In-line type fuel feed pump of high-pressure common rail system

A high-pressure common rail system and in-line technology, applied in the direction of charging systems, fuel injection pumps, engine components, etc., can solve the problems of high-pressure sealing complexity, high manufacturing cost, and difficult processing, and achieve simplified structure, easy manufacturing, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and working principle of the oil supply pump of the present invention will be further described below in conjunction with specific embodiments.

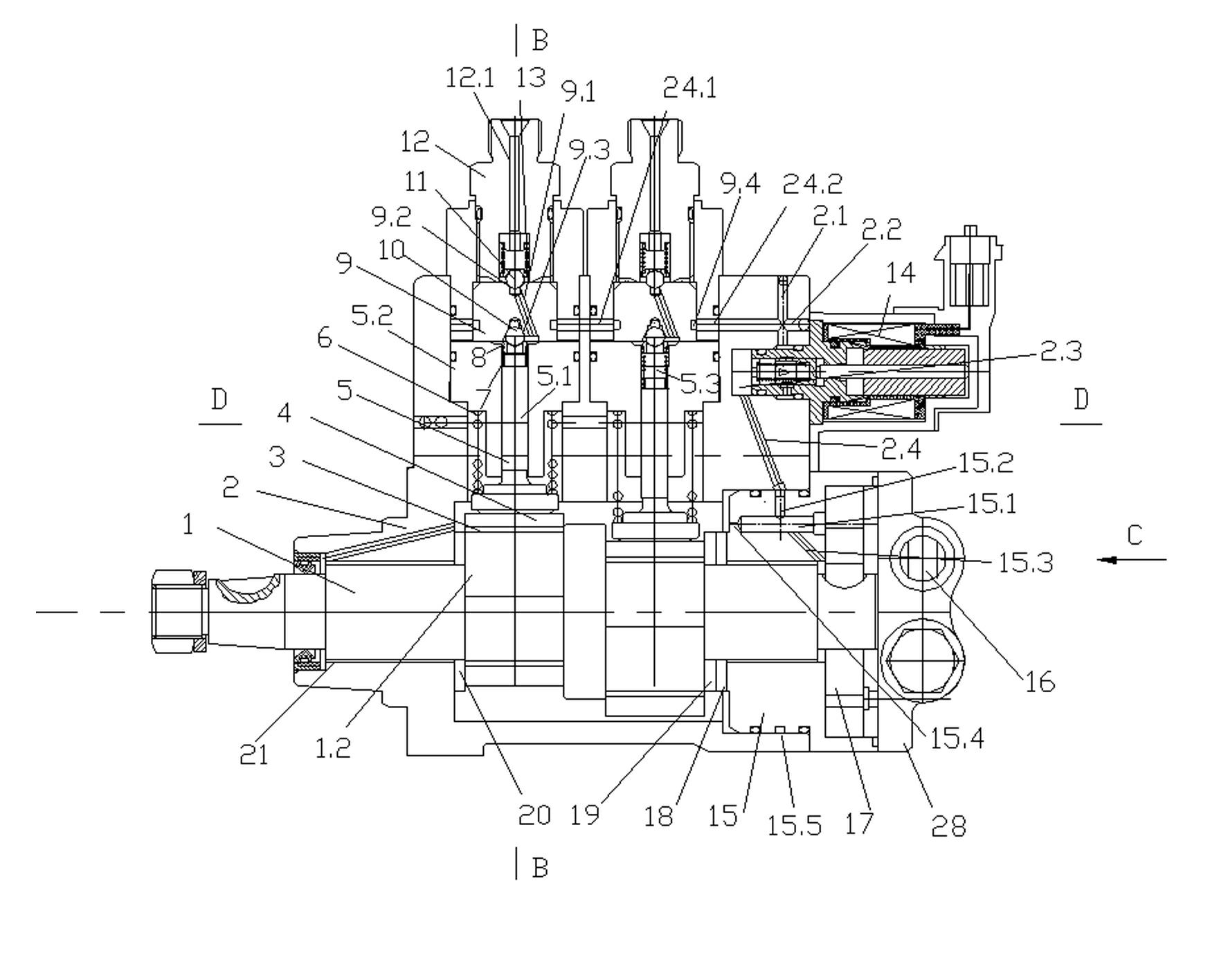

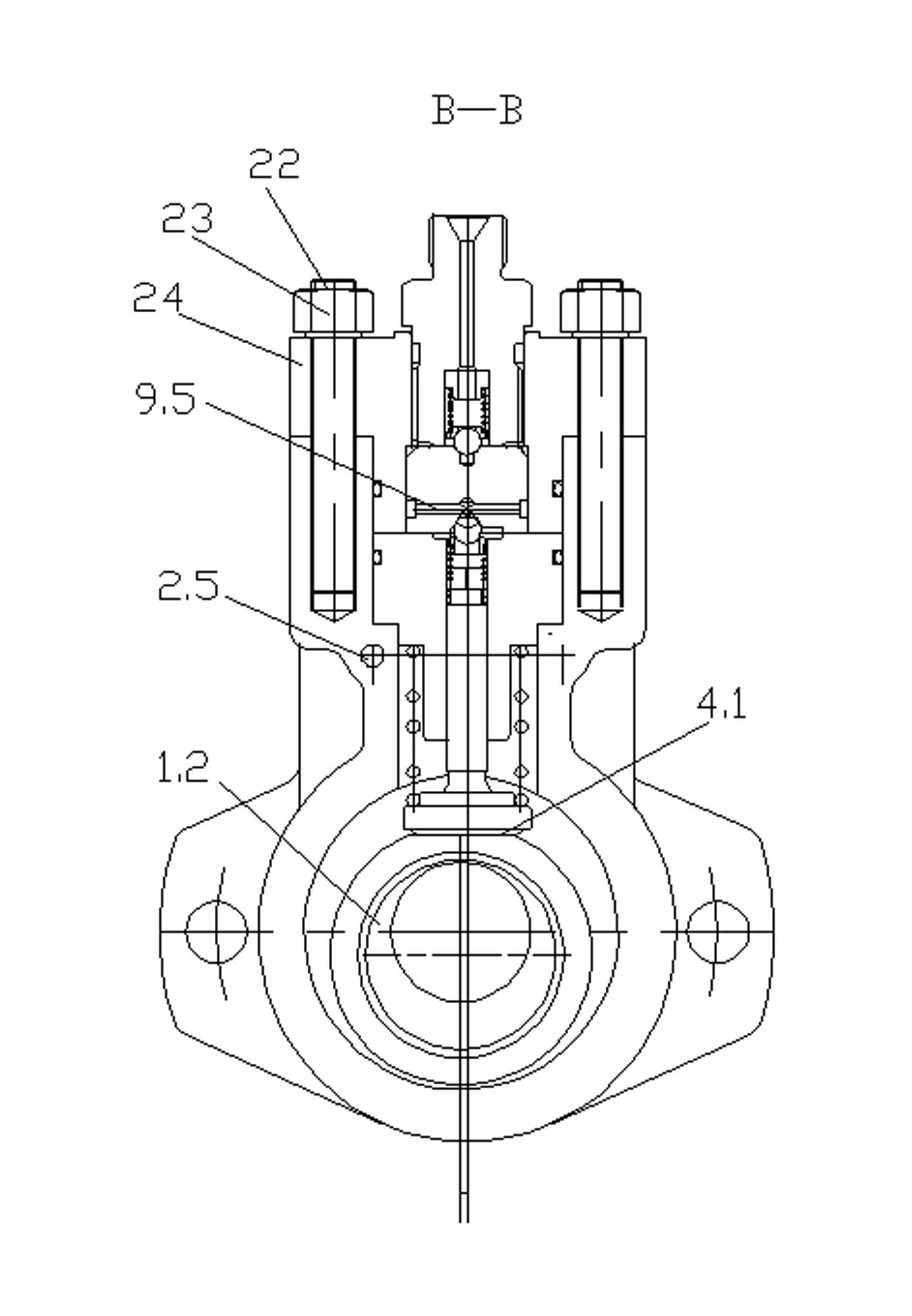

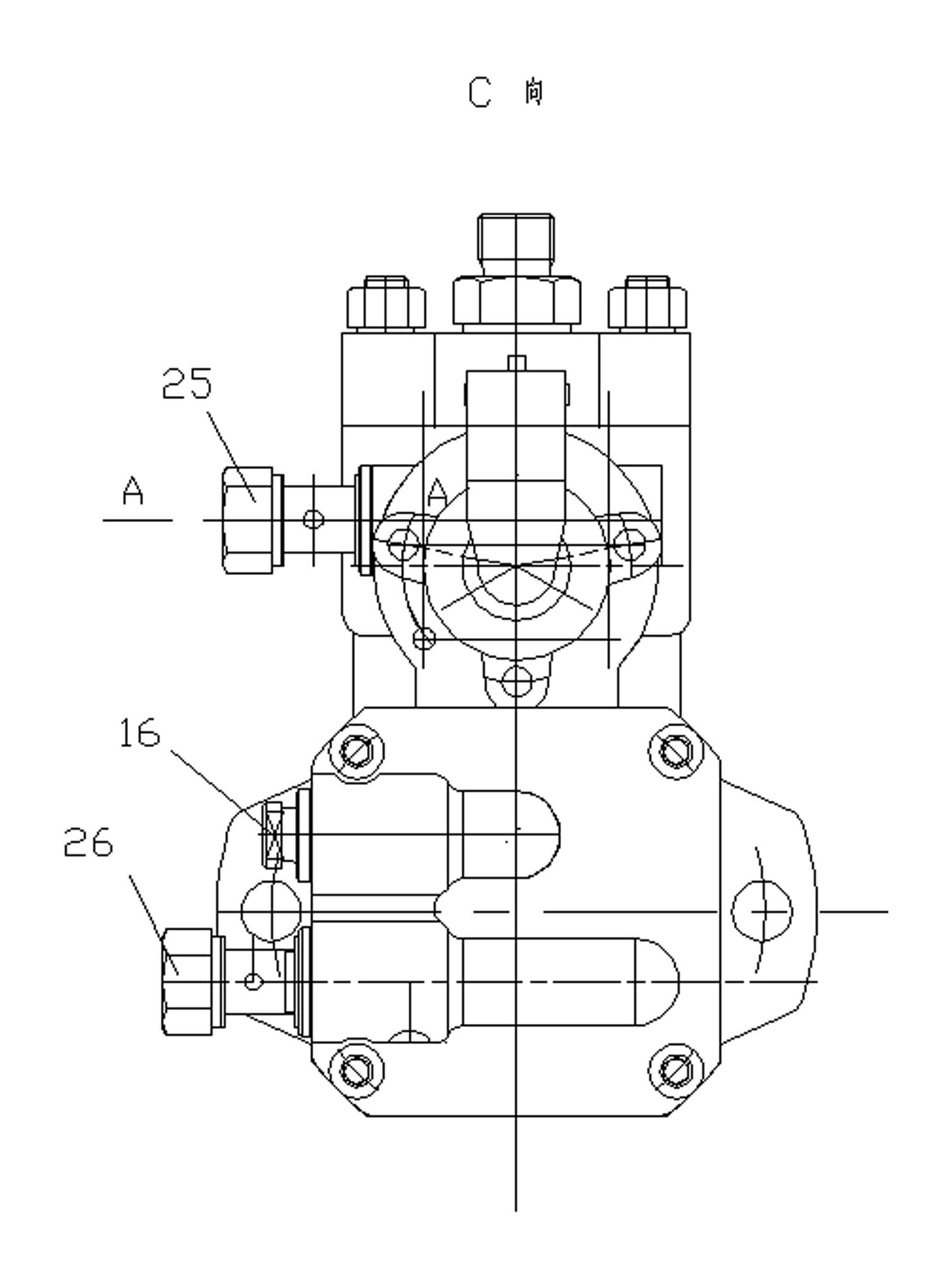

[0015] Such as Figure 1~4 As shown: the present invention includes a double-cylinder in-line oil supply pump, which is characterized in that: the camshaft of the double-cylinder in-line oil supply pump body is provided with two sets of mutually independent cam mechanisms and an oil circuit group connected to the cam mechanism; The two sets of cam mechanisms described above are fixed on the camshaft of the pump body through eccentric wheels, and the eccentric circles of the two sets of cam mechanisms are set on the camshaft in opposite directions, and an oil inlet and outlet ball valve is also arranged above the cam structure Common seat.

[0016] The cam mechanism includes an eccentric circle 1.2, a ring 4, a plunger spring 6, a plunger 5.1, a plunger flange sleeve 24, a plunger coupling 5, a valve seat 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com