Monitoring system for element in gas in pipeline and operation method thereof

A monitoring system and element technology, applied in the direction of measuring devices, preparation of test samples, color/spectral characteristic measurement, etc., can solve the problems of high cost, complex structure, troublesome system maintenance, etc., and achieve easy maintenance and high system reliability , save the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

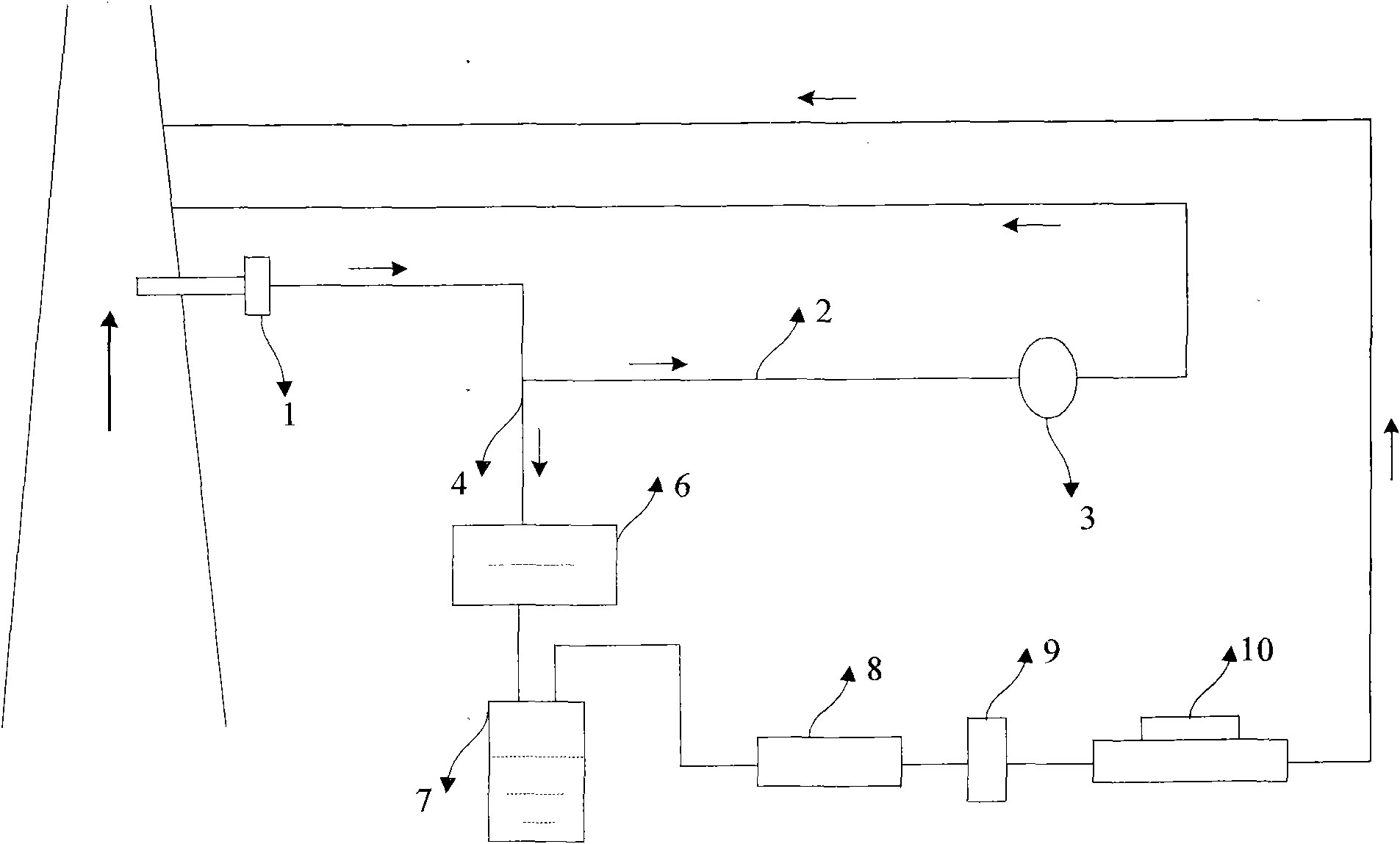

[0047] figure 2 A basic structural diagram of a monitoring system for elements in gas in a chimney according to an embodiment of the present invention is schematically given. Such as figure 2 As shown, the monitoring system includes:

[0048] Sampling probe 1, the sampling probe is installed on the chimney.

[0049] The first pipeline 2 and the air extraction device 3 , under the action of the air extraction device 3 , the gas in the chimney flows back into the pipeline after passing through the sampling probe 1 and the first pipeline 2 . A heat tracing module is arranged on the first pipeline 2 .

[0050] The second pipeline 4 , one end of the second pipeline 4 is opened in the first pipeline 2 , and the other end is connected to the element enrichment device 6 .

[0051] The element enrichment device 6 is used for enriching mercury, cadmium, arsenic and other elements in the sampled gas.

[0052] The measuring unit is used for measuring the enriched mercury, cadmium, ...

Embodiment 2

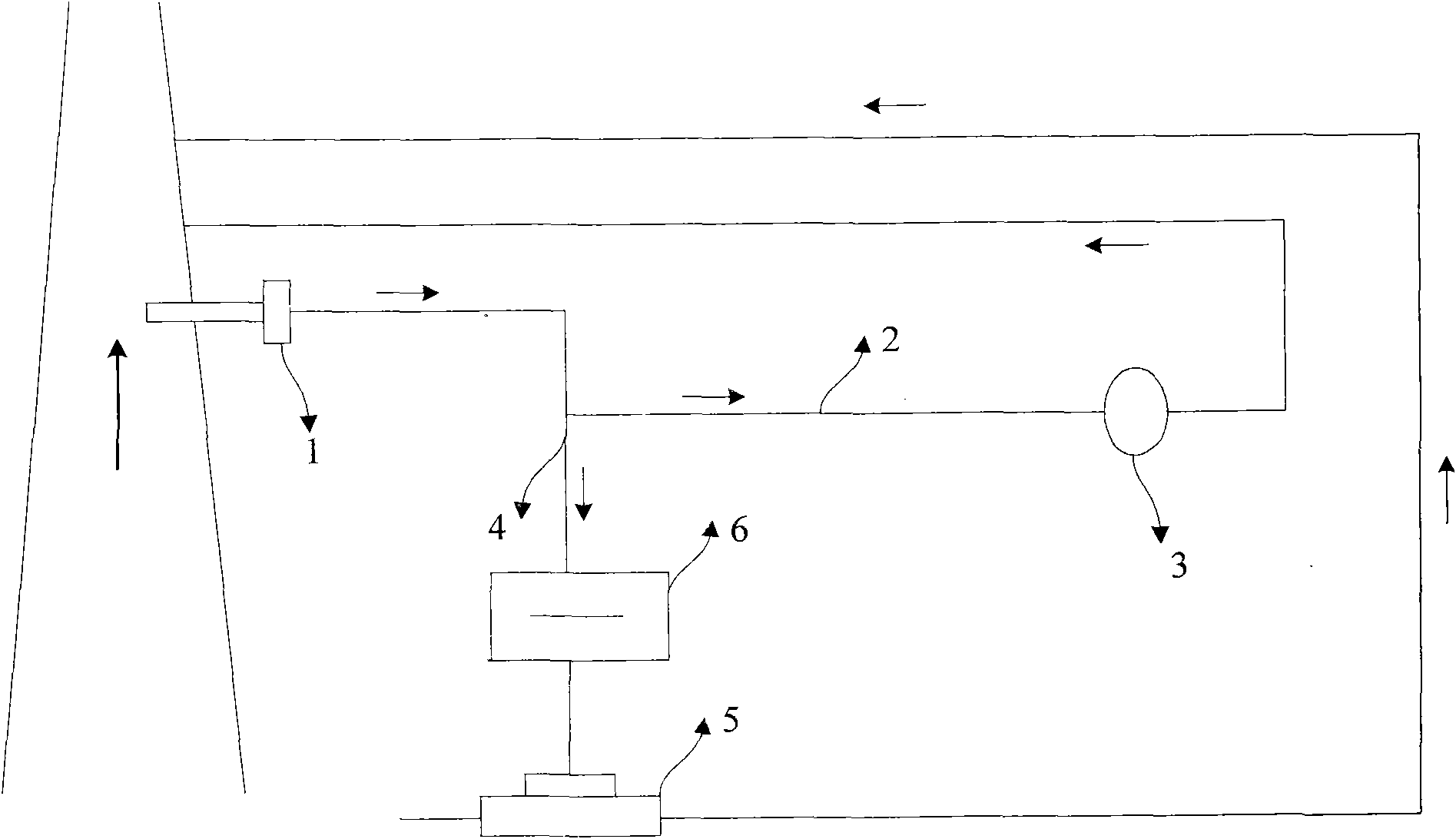

[0071] The monitoring system of element in the gas in the chimney is different from embodiment 1:

[0072] The monitoring system further includes a heating device, the heating device is arranged on the volume measuring device to prevent components in the gas from being precipitated and blocking the channel due to cooling down when passing through the volume measuring device, effectively prolonging the continuous working time of the volume measuring device, Reduced work maintenance.

Embodiment 3

[0074] The monitoring system of element in the gas in the chimney is different from embodiment 1:

[0075] 1. The volume measuring device adopts a diaphragm pump, so that under the action of the diaphragm pump, the gas passes through the small hole at the speed of sound.

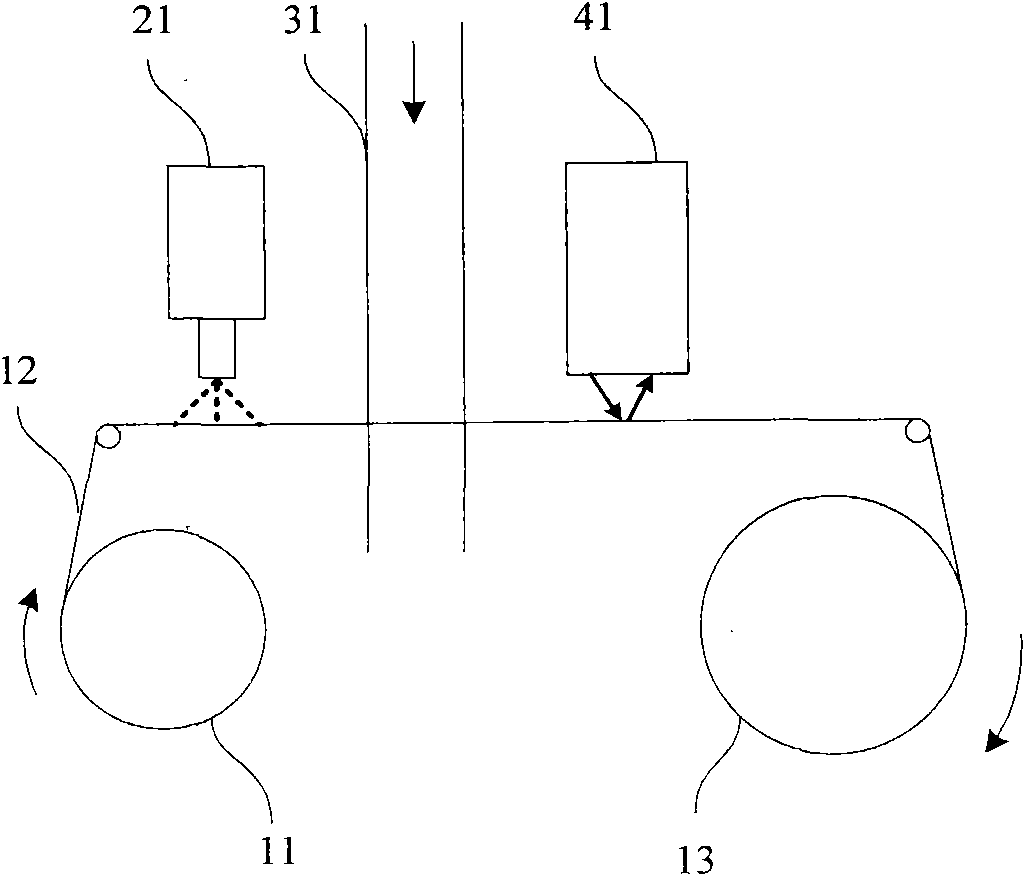

[0076] 2, Figure 6 shows the basic structural diagram of the solution application unit in Embodiment 3 of the present invention, as Figure 6 As shown, the sulfur solution applying unit 22 is a sealed container containing sulfur solution, and the solvent is carbon disulfide. The filter membrane 12 moves between the supporting rollers 221, 222, 223, and passes through the sulfur solution in the container to keep hermetically sealed with the container, so as to prevent the solution in the container from being volatilized and discharged from the container.

[0077] 3. The detection unit is a cold vapor atomic absorption spectrometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com