Method for determining expansion process parameters of tube and tube plate of AP1000 nuclear evaporator

A technology of nuclear power evaporator and process parameters, which is applied in the field of nuclear power equipment manufacturing, can solve the problem that the second-generation expansion joint process parameters cannot be used, and there is no AP1000 third-generation nuclear power evaporator tube/tube sheet expansion joint process parameters determination method, etc. problems, to achieve the effect of reducing the test cost and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

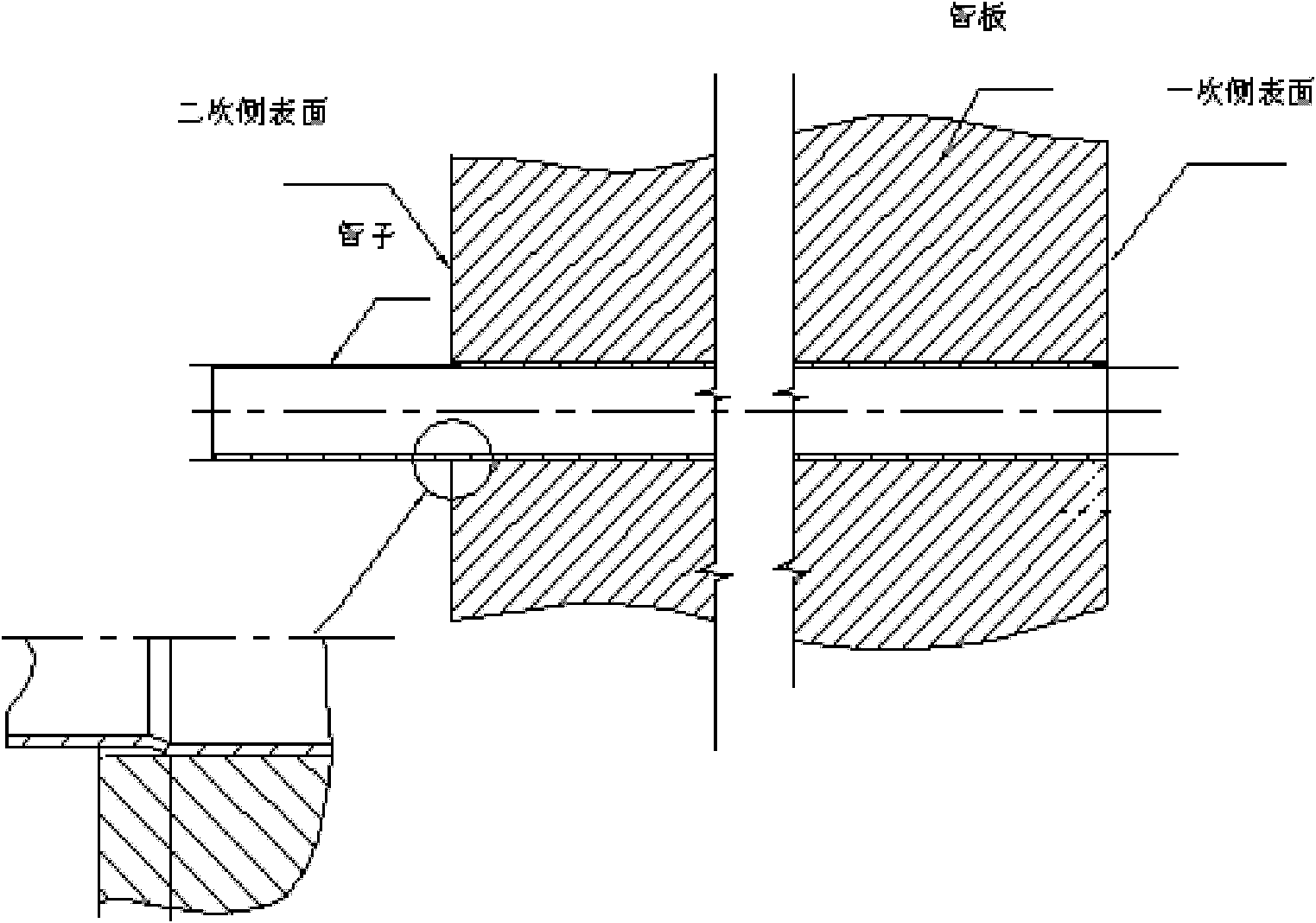

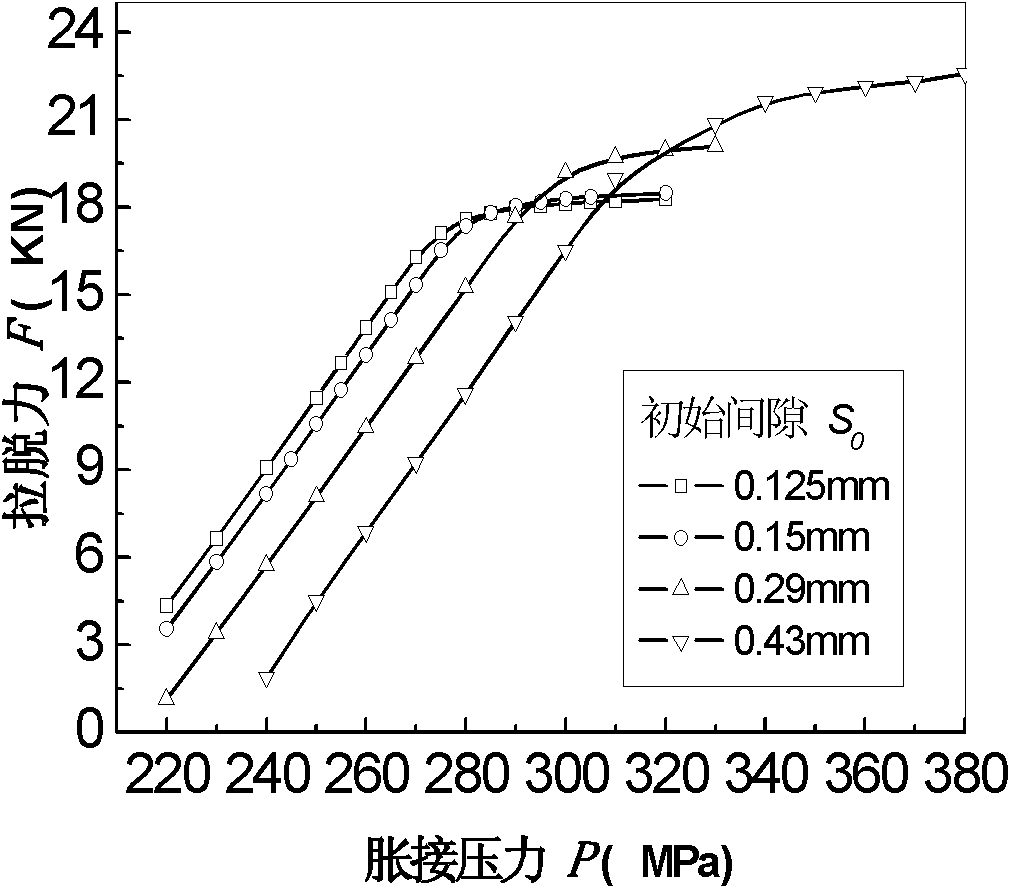

[0065] (1) According to the ASME code of the United States, the axial load L=A in the design of the expansion joint between the pipe and the tube sheet t ×S y × f r , where A t is the cross-sectional area of the heat transfer tube, S y is the minimum yield strength of the heat transfer tube material at the operating temperature, f r is the joint reliability factor, and its minimum value is 0.7 (according to the ASME code, the minimum value is 0.7, if it is lower than 0.7, the joint is unreliable). for figure 1 For the AP1000 heat transfer tube shown in , the outer diameter of the tube is 17.48mm and the inner diameter of the tube is 15.46mm, and the wall thickness of the tube is t=(17.48-15.46) / 2=1.01mm, then the calculated value of the cross-sectional area of the tube is A t =52.23mm 2 , from the ASME code, the minimum yield strength S of the Alloy 690 pipe at an operating temperature of 340°C y =190MPa, f r The value of is taken as 0.7, then the calculated axial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com