Energy dissipating and damping type multi-ribbed composite wallboard and manufacturing method thereof

A technology of composite wall panels and manufacturing methods, which is applied in the direction of shock resistance, manufacturing tools, ceramic molding machines, etc., can solve the problems of frequent replacement and maintenance of filling blocks, and achieve the effect of delaying the damage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

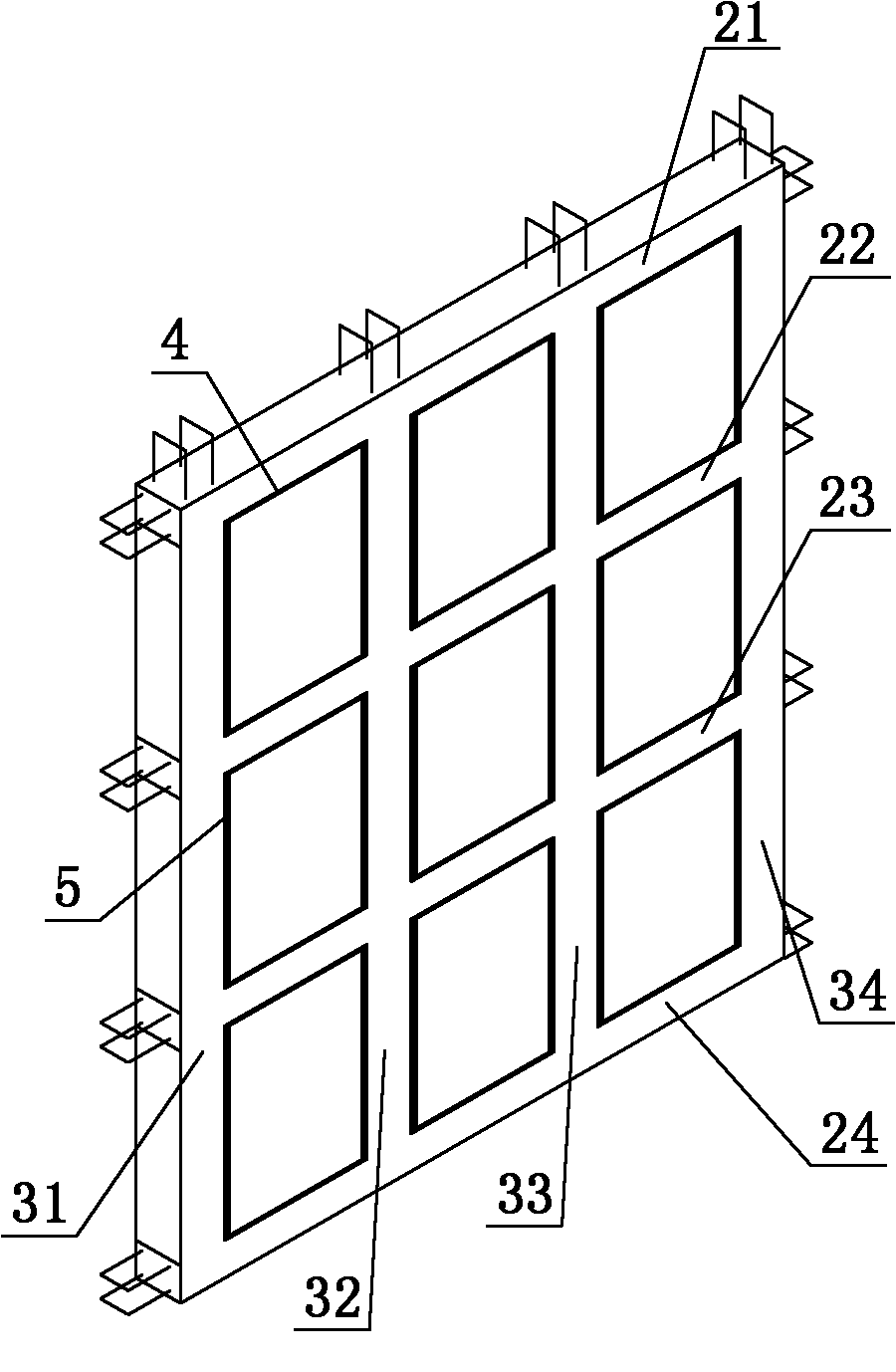

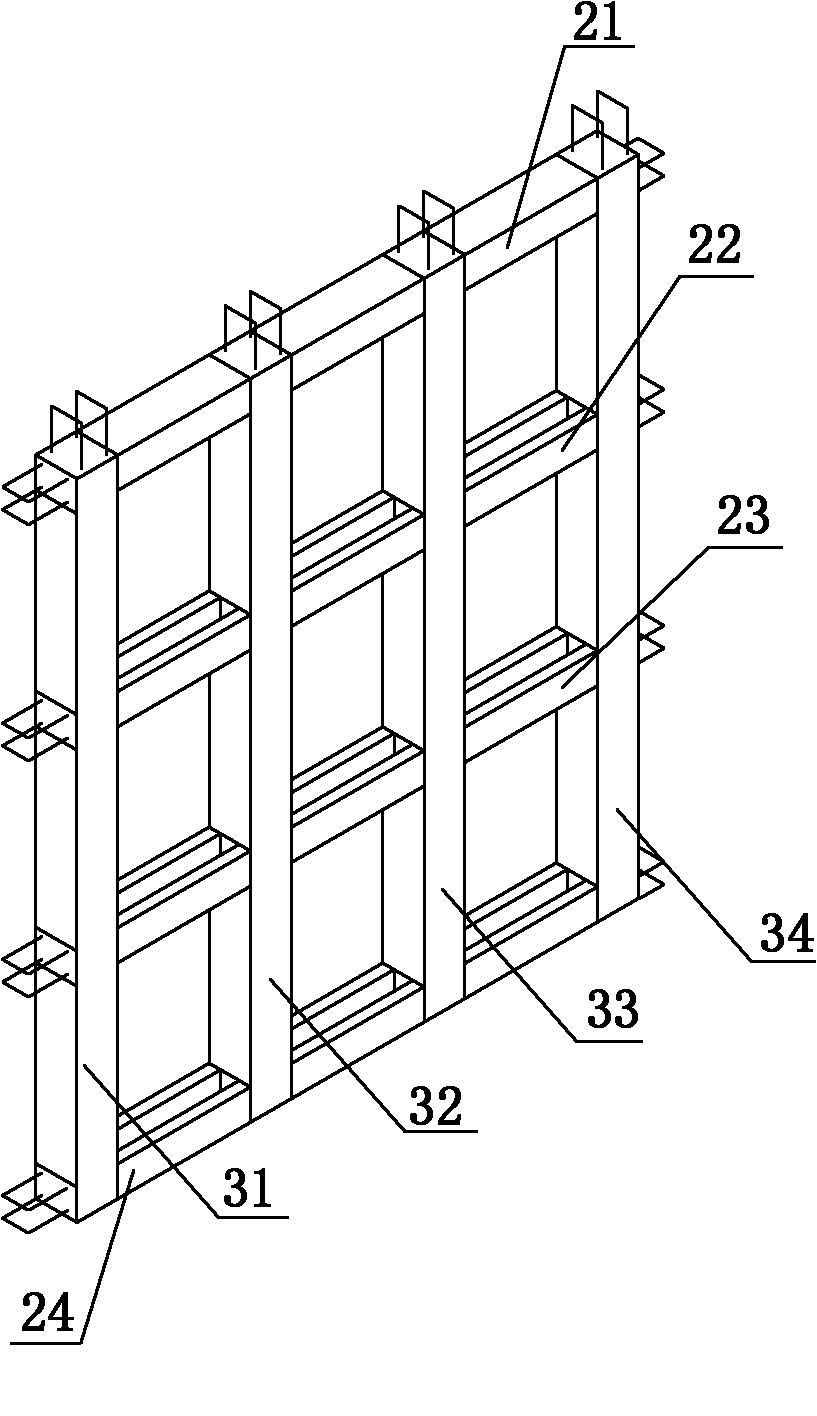

[0063] Fabrication of energy-dissipating and shock-absorbing densely ribbed composite wall panels with rectangular grooves and grooves with a 3×3 reinforced concrete grid with a size of 3000mm×3000mm×250mm, see figure 1 , figure 2 , whose production steps include:

[0064] Step 1, make a 3×3 reinforced concrete grid according to the following dimensions.

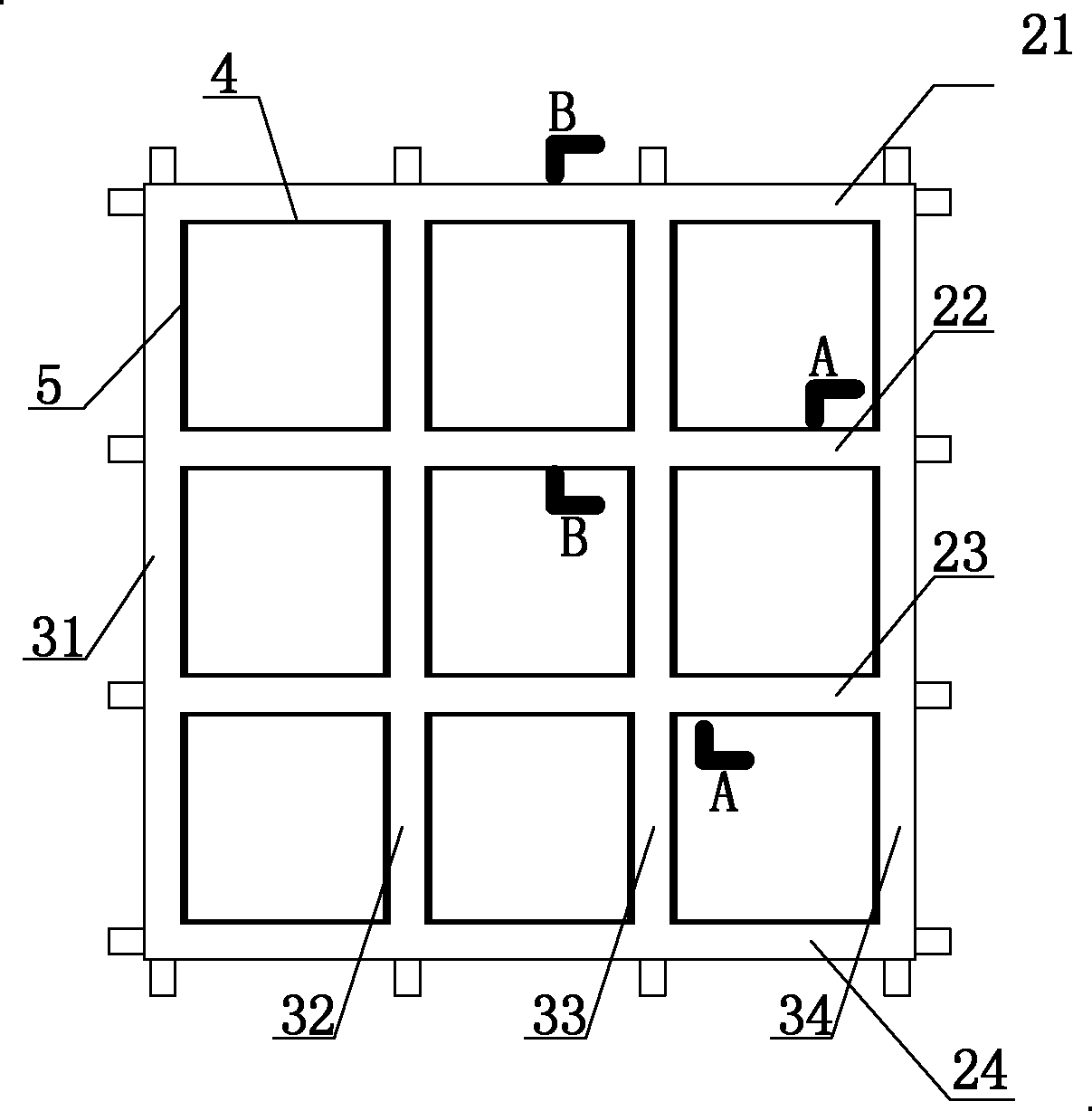

[0065] The reinforced concrete top rib beam 21 and the reinforced concrete bottom rib beam 24 have cross-sectional dimensions of 200mm×130mm, and the cross-sectional dimensions of the first reinforced concrete middle rib beam 22 and the second reinforced concrete middle rib beam 23 are 200mm×160mm.

[0066] The cross-sectional dimensions of the first to fourth reinforced concrete rib columns 31, 32, 33, 34 are 200mm×150mm.

[0067] The above-mentioned four reinforced concrete rib beams and four reinforced concrete rib columns constitute nine empty reinforced concrete grids with a size of 800mm×800mm×200mm.

[0068] Arran...

example 2

[0074] The difference between the second engineering example and the first engineering example is that the coating thickness of the graphite lubricating layer 4 is 4mm. The viscoelastic material cushion layer 5 has a thickness of 2 cm. The material for filling blocks is plant fiber concrete.

example 3

[0076] Fabrication of energy-dissipating and shock-absorbing densely ribbed composite wall panels with dovetail-shaped grooves and 3×3 reinforced concrete grids with a size of 3000mm×3000mm×250mm, see figure 1 , figure 2 , whose production steps include:

[0077] Step 1, make a 3×3 reinforced concrete grid according to the following dimensions.

[0078] The reinforced concrete top rib beam 21 and the reinforced concrete bottom rib beam 24 have cross-sectional dimensions of 200mm×130mm, and the cross-sectional dimensions of the first reinforced concrete middle rib beam 22 and the second reinforced concrete middle rib beam 23 are 200mm×160mm.

[0079] The cross-sectional dimensions of the first to fourth reinforced concrete rib columns 31, 32, 33, 34 are 200mm×150mm.

[0080] The above-mentioned four reinforced concrete rib beams and four reinforced concrete rib columns constitute nine empty reinforced concrete grids with a size of 800mm×800mm×200mm.

[0081] Arrange and bin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com