Small-curvature radius complex curved surface intelligent ultrasonic thickness measurement system

A complex surface, ultrasonic technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of the measurement accuracy not meeting the requirements, the measurement range is limited, etc., to achieve low cost, simple structure, intuitive display Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

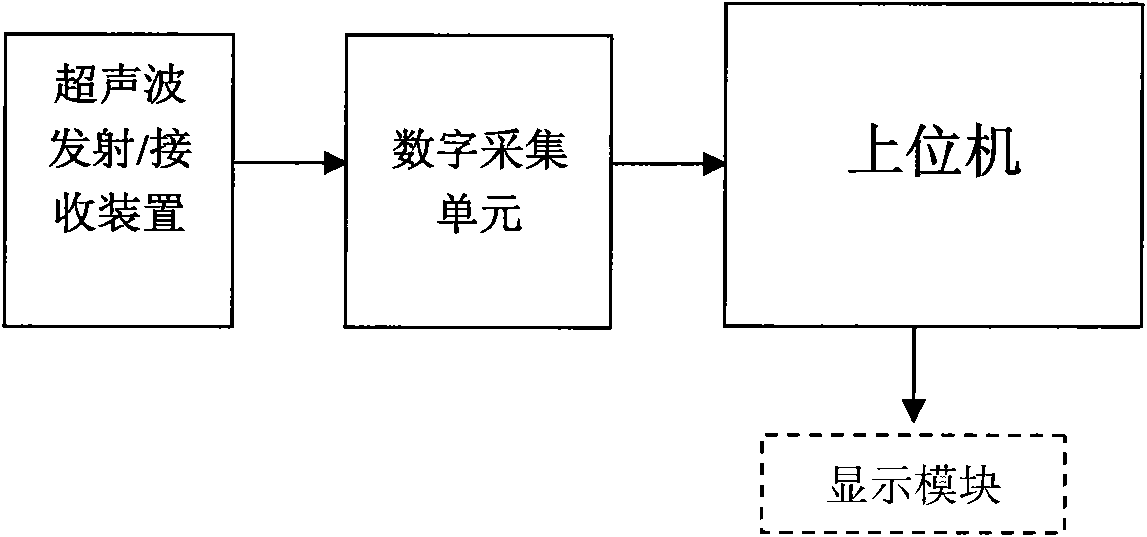

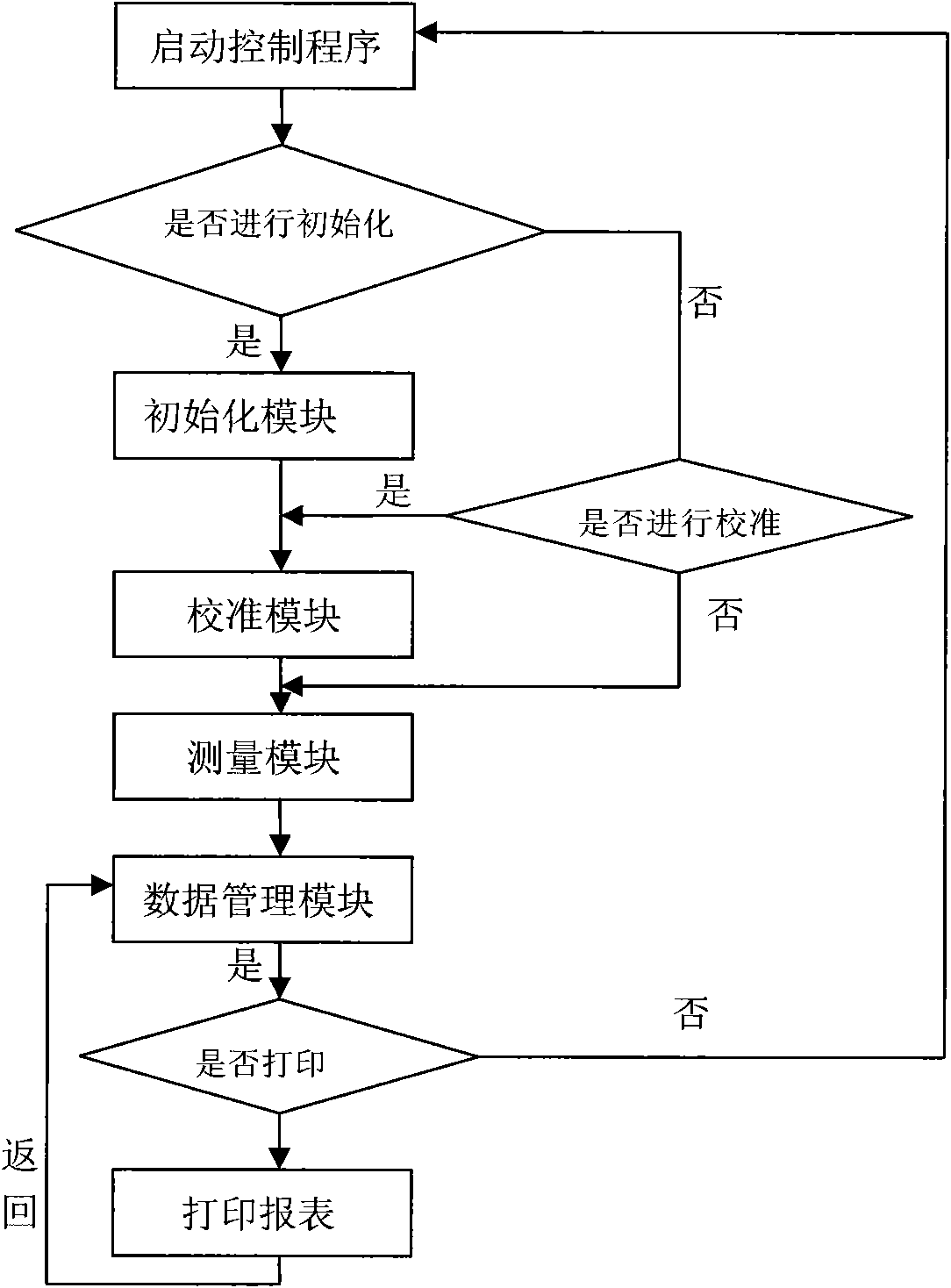

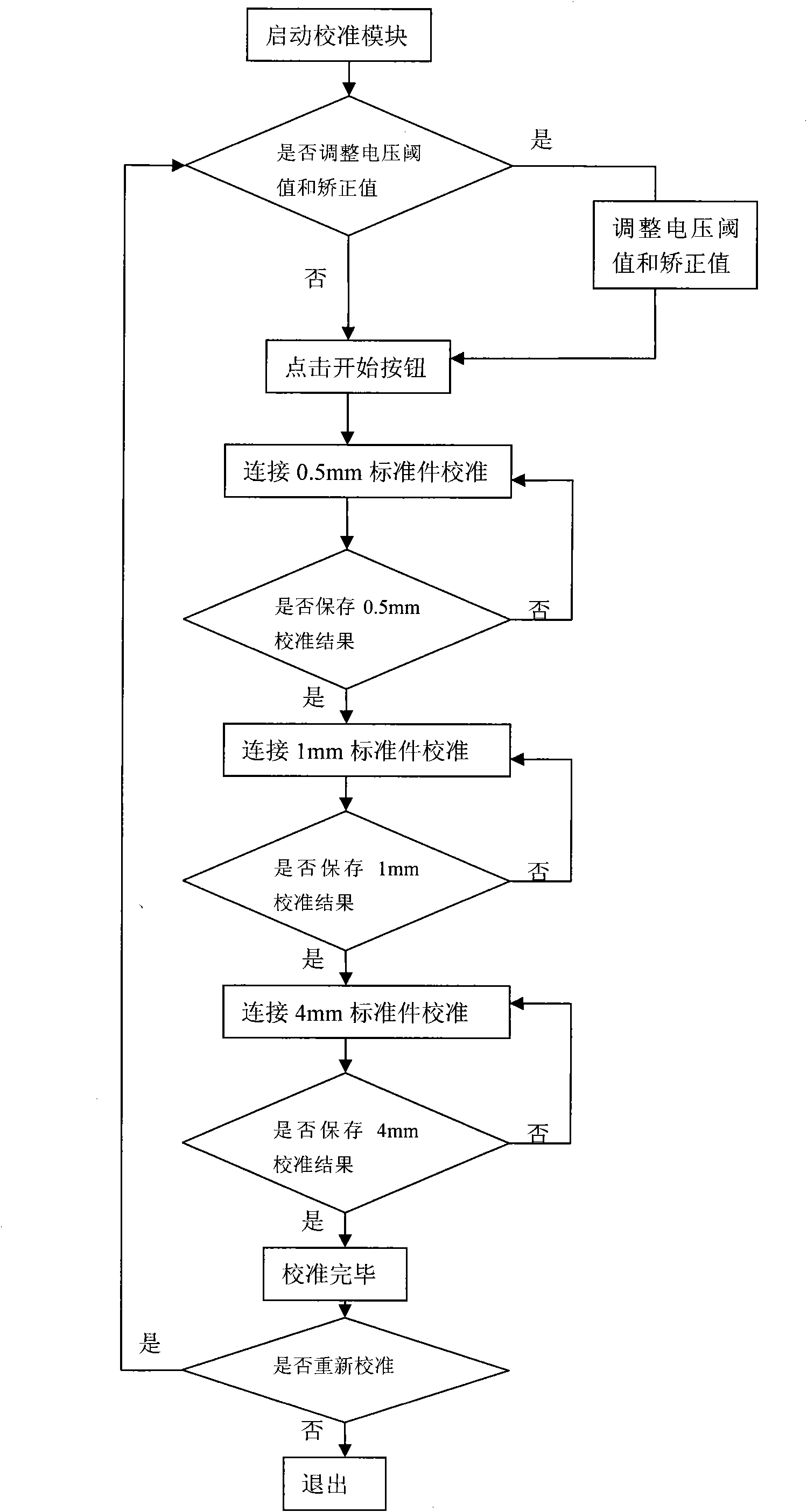

[0037] like Figure 1-6 As shown in the figure, an intelligent ultrasonic thickness measurement system with small curvature radius and complex curved surface includes a host computer, a digital acquisition unit and a display module. The host computer receives the digital signal from the digital acquisition unit, and the host computer outputs the received digital signal To the display module display; the signal input end of the digital acquisition unit is connected to the ultrasonic transmitting / receiving device; the ultrasonic transmitting / receiving device transmits the ultrasonic signal to the measured object through the ultrasonic probe, and the ultrasonic transmitting / receiving device receives the measured object The returned ultrasonic signal; the digital acquisition unit converts the returned ultrasonic signal of the measured object into a digital signal and outputs it to the host computer.

[0038] The upper computer adopts Advantech PT610 dual-core processor, main frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com