Tester for measuring degassing rate of dangerous chemical under condition of meeting water

A technology of dangerous chemicals and outgassing rate, which is applied in the direction of instruments and analytical materials, can solve problems such as test errors, calculation deviations, hazards, etc., and achieve the effects of saving tediousness, preventing backflow, and avoiding hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

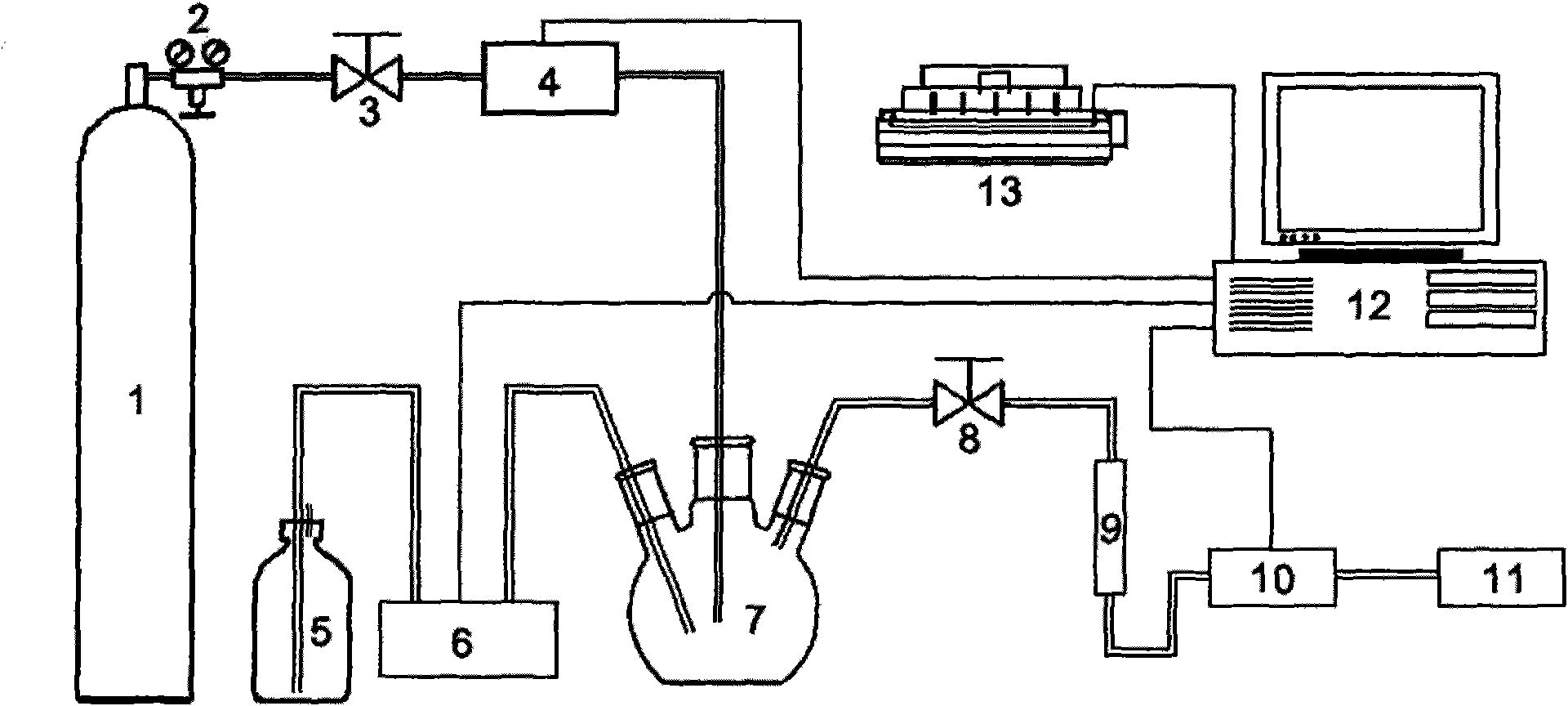

[0012] As shown in the accompanying drawings, the three-necked flat-bottomed flask in the present invention is a reaction bottle (7) for degassing when encountering water, one of which is connected to the infusion pump (6), and the inlet of the infusion pump is connected to the liquid storage bottle (5), and the nitrogen cylinder (1) The nitrogen in the tank enters the inlet of the solenoid valve (3) after passing through the pressure reducing valve (2) and the gas pipeline, and the constant flow of nitrogen gas from the solenoid valve (3) is introduced into the first stage of the reaction bottle (7) through the pressure sensor (4). Two bottle mouths, the gas generated by the reaction with water flows out from the third mouth of the reaction bottle (7) along with the constant nitrogen flow, and enters the air flow meter (10) after passing through the solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com