Photodiffusion film and preparation method thereof

A technology of light diffusion film and diffusion layer, applied in optics, nonlinear optics, instruments, etc., can solve the problem of poor light diffusion performance of light diffusion film, and achieve improved light diffusion performance, good light diffusion performance, and good light diffusion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

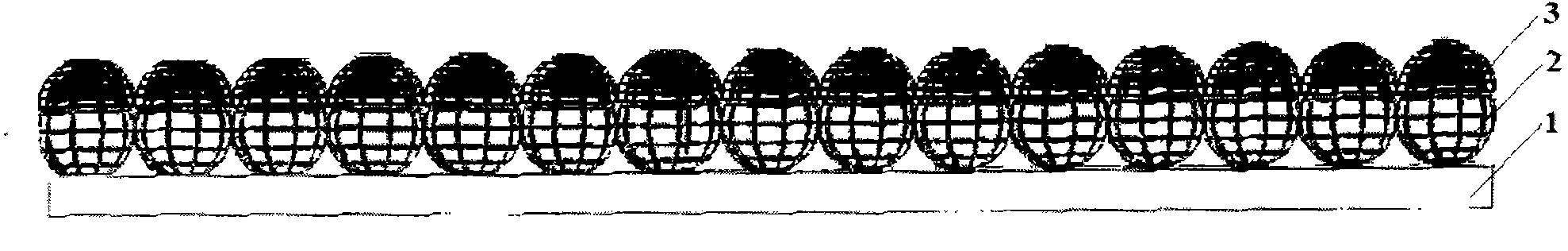

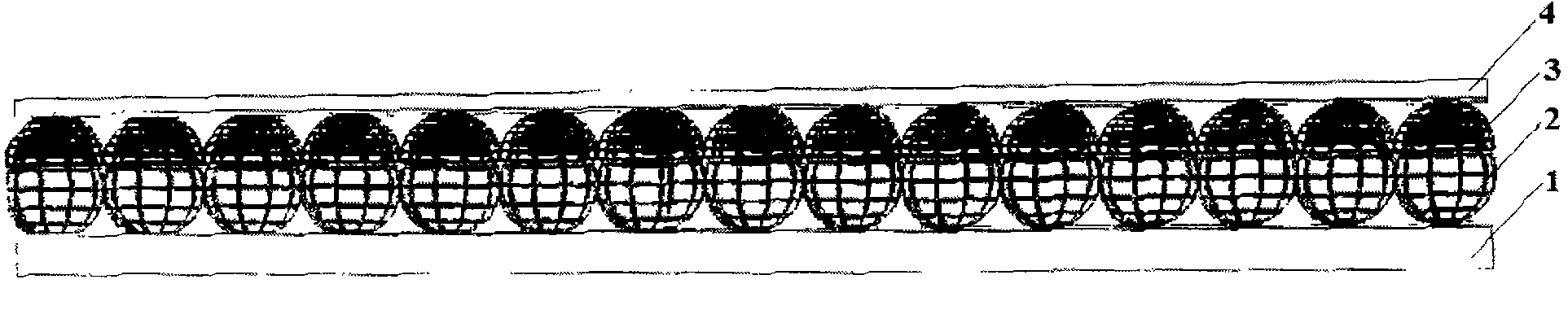

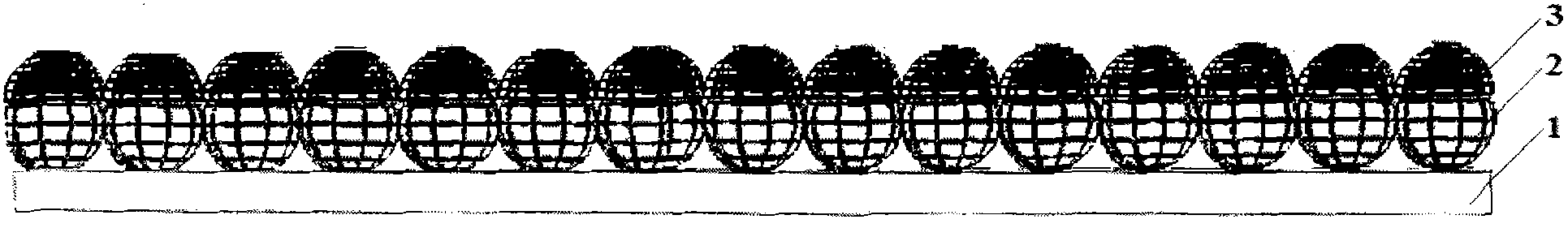

[0023] The present invention also provides a method for preparing a light-diffusing film, the method comprising sequentially forming a first diffusion layer 2 and a second diffusion layer 3 on one surface of a transparent substrate 1, the first diffusion layer 2 being composed of average particle Spherical diffusion particles with a diameter of 0.1-5 microns are formed, and are formed by a method of self-assembly into a film, and the second diffusion layer 3 is coated on the first diffusion layer 2 .

[0024] According to the method provided by the present invention, in order to further reduce the thickness of the light-diffusing layer in the final light-diffusing film, and then achieve the effect of reducing the thickness of the light-diffusing film, the method of self-assembled film is preferably include:

[0025] (a) making the spherical diffusing particles into a colloid, and diffusing the colloid into a film;

[0026] (b) make described transparent substrate 1 be placed ...

Embodiment 1

[0043] This embodiment is used to illustrate the light-diffusing film provided by the present invention and its preparation method.

[0044] (1) Form the first diffusion layer

[0045] a. Corona treatment is carried out on a transparent base material with a thickness of 30 microns formed by polyethylene terephthalate (purchased from Toray, Japan, model T60), and then cut into transparent base sheets of 80 mm × 80 mm ;

[0046] b. Fill a 500 ml beaker (the bottom is provided with a water gate) with pure water, then immerse the cut transparent substrate in step a into the bottom of the beaker;

[0047] c. Clean the glass flakes ultrasonically, and then dry them at 100°C for 30 minutes;

[0048] d. Add spherical silica particles with an average particle diameter of 1 micron (the difference between the largest particle diameter and the smallest particle diameter is 1 micron) to absolute ethanol, and then ultrasonically disperse it in an ultrasonic cleaner for 30 minutes, thereby...

Embodiment 2

[0058] This embodiment is used to illustrate the light-diffusing film provided by the present invention and its preparation method.

[0059] (1) Form the first diffusion layer

[0060] a. Corona treatment is carried out on a transparent substrate with a thickness of 100 microns formed by polystyrene (purchased from Nantong Ruiao Electronic Technology Co., Ltd., model BOPS38), and then cut into transparent substrates of 80 mm × 80 mm;

[0061] b. Fill a 500 ml beaker (the bottom is provided with a water gate) with pure water, then immerse the cut transparent substrate in step a into the bottom of the beaker;

[0062]c. Clean the glass flakes ultrasonically, and then dry them at 100°C for 30 minutes;

[0063] D, the average particle diameter is 3 micron spherical polymethacrylate particles (the difference between the maximum particle diameter and the minimum particle diameter is 1.5 micron) in dehydrated alcohol, then ultrasonically dispersed in an ultrasonic cleaner for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com