Piezoelectric flat panel loudspeaker with distributed ceramic wafers

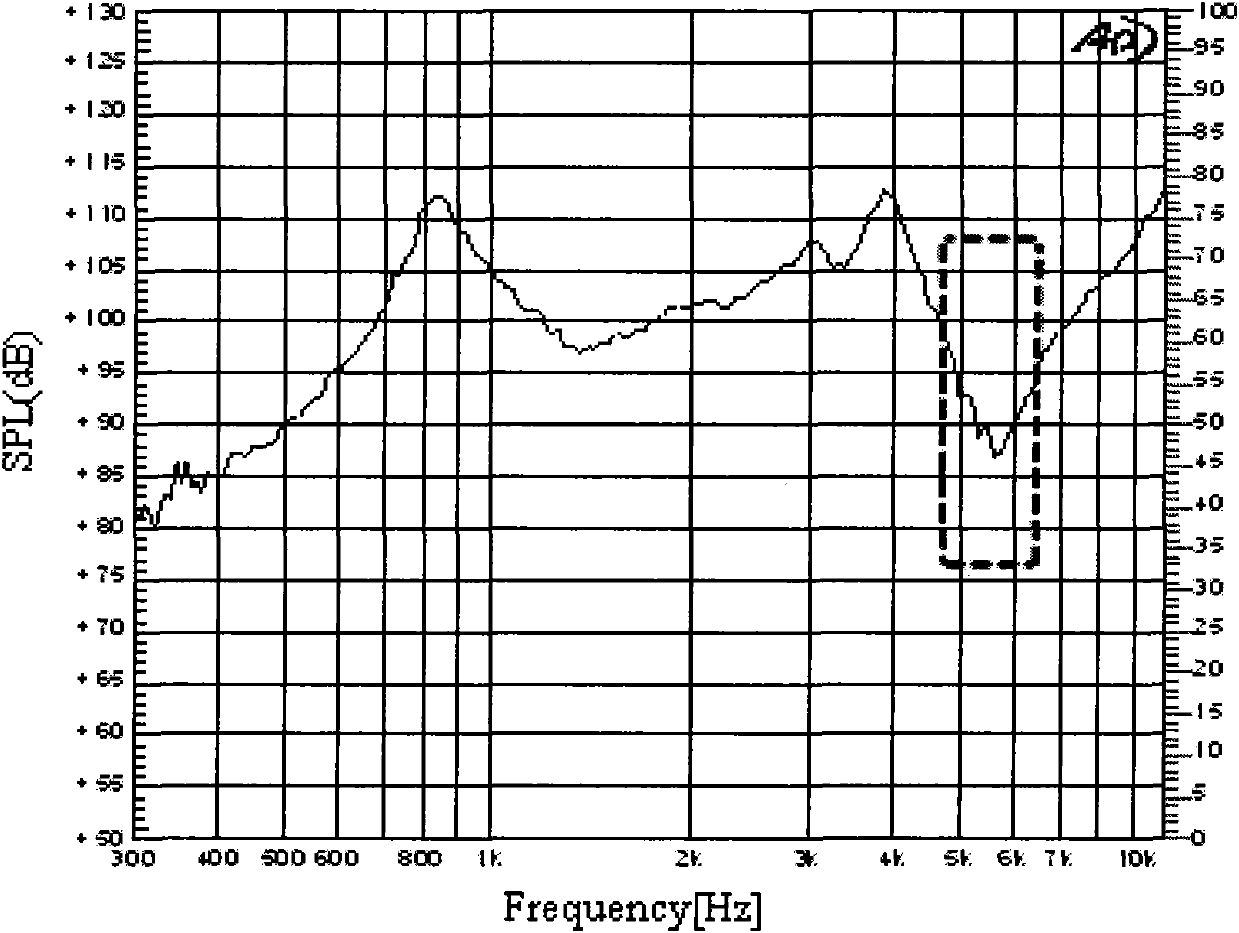

A flat-panel loudspeaker, distributed technology, applied in the direction of piezoelectric/electrostrictive transducers, sensors, electrical components, etc., can solve problems that restrict the popularization and application of piezoelectric loudspeakers, achieve better sound quality, eliminate peaks and The effect of improving the flatness of valley and sound pressure level curves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

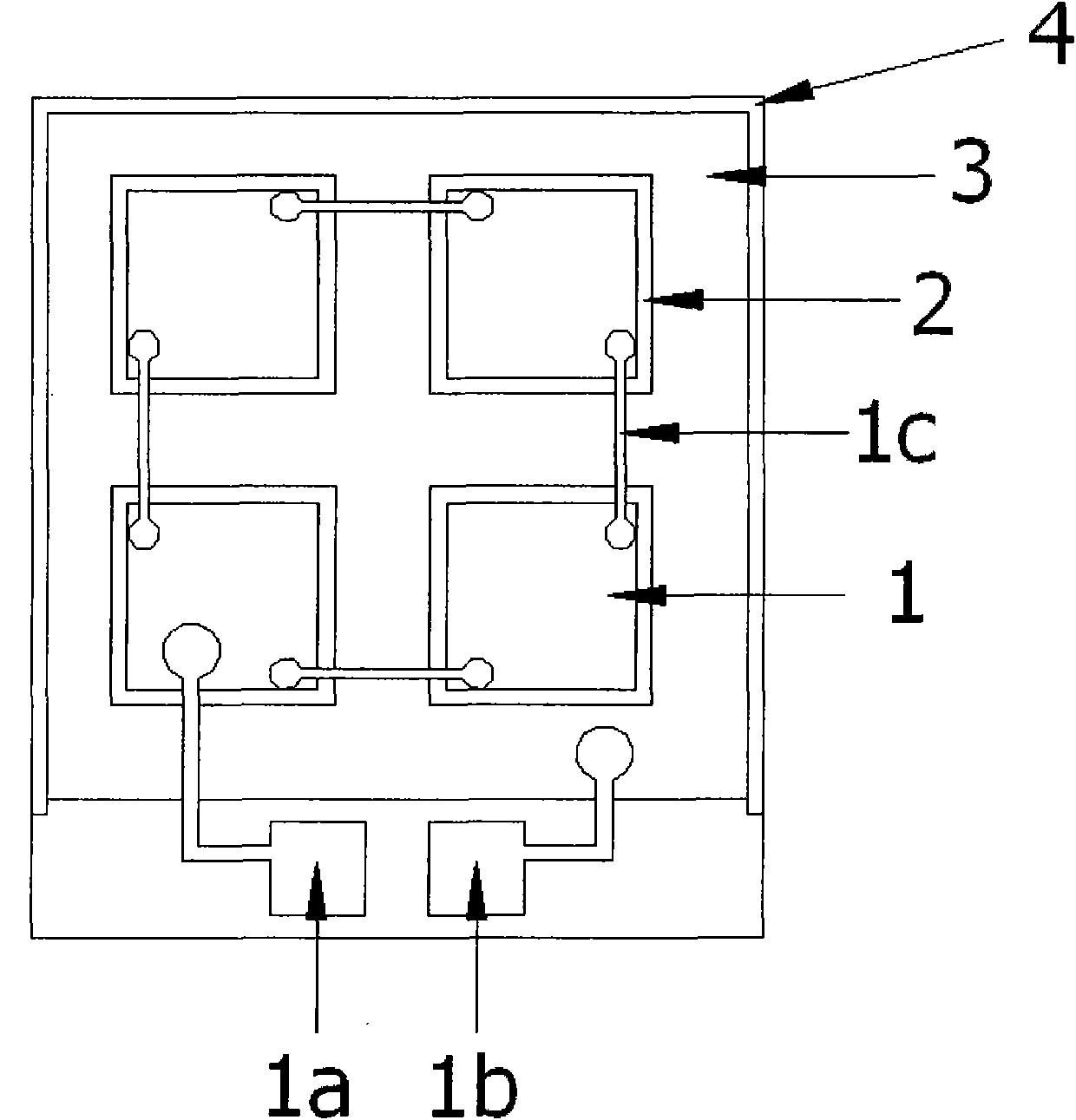

[0038]Figure 3(a) and Figure 3(b) are the front view and exploded view of Embodiment 1 of the present invention. The electrode 1 is divided into a positive electrode and a negative electrode, which are distributed on the upper surface and the lower surface of the piezoelectric ceramic sheet 2 . The piezoelectric ceramic sheet 2 includes four small rectangular sheets, which are pasted on the upper surface of the diaphragm 3 in a two-by-two matrix arrangement or eight small rectangular sheets are respectively bonded on the top of the diaphragm 3, lower surface. The vibrating membrane 3 is rectangular, made of nickel-iron alloy or stainless steel, and the layer thickness is controlled within 30 microns to 100 microns. The frame 4 constrains and fixes the diaphragm 3 . The positive electrode lead 1a and the negative electrode lead 1b respectively lead the positive electrode and the negative electrode to corresponding solder points on the frame to facilitate connection to externa...

Embodiment 2

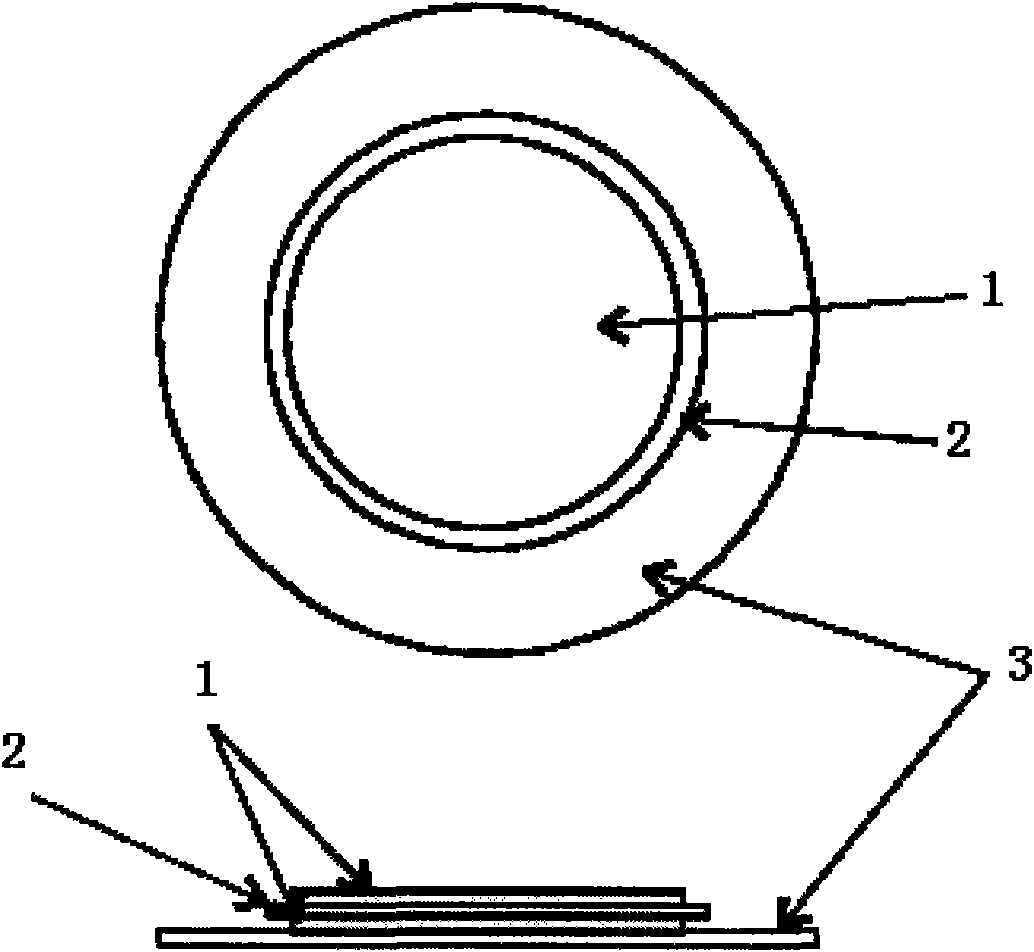

[0040] Figure 5(a) and Figure 5(b) are the front view and exploded view of Embodiment 2 of the present invention. The electrode 1 is divided into a positive electrode and a negative electrode, which are distributed on the upper surface and the lower surface of the piezoelectric ceramic sheet 2 . The piezoelectric ceramic sheet 2 includes four small 90-degree sector-shaped pieces, which are pasted on the upper surface of the diaphragm 3 in an arrangement of 90-degree intervals in a circular array, or eight small 90-degree sector-shaped pieces are respectively bonded to the diaphragm 3's upper and lower surfaces. The vibrating membrane 3 is circular or oval, made of nickel-iron alloy or stainless steel, and the layer thickness is controlled within 30 microns to 100 microns. The frame 4 constrains and fixes the diaphragm 3 . The positive electrode lead 1a and the negative electrode lead 1b respectively lead the positive electrode and the negative electrode to corresponding sold...

Embodiment 3

[0042] Figure 6(a) and Figure 6(b) are the front view and exploded view of Embodiment 3 of the present invention. The electrode 1 is divided into a positive electrode and a negative electrode, which are distributed on the upper surface and the lower surface of the piezoelectric ceramic sheet 2 . The piezoelectric ceramic sheet 2 includes four small rectangular sheets, which are pasted on the upper surface of the diaphragm 3 in a two-by-two matrix arrangement or eight small rectangular sheets are respectively bonded on the top of the diaphragm 3, lower surface. The vibrating membrane 3 also adopts four small vibrating membranes, which are arranged in a two-by-two matrix and correspond one-to-one in space to the four piezoelectric ceramics arranged in a two-by-two matrix. Each small piece of the vibrating membrane 3 They are connected at the junction 3a of the diaphragms of the blocks, and the diaphragm 3 is made of nickel-iron alloy or stainless steel, and the layer thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com