Auxiliary cooling device for connection to aircraft liquid cooling system

An auxiliary cooling and liquid cooling technology, applied in aircraft parts, ground equipment, transportation and packaging, etc., can solve the problems of reduced payload, large installation space, high fuel consumption, etc., and achieve less space, simplified integration, and low weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

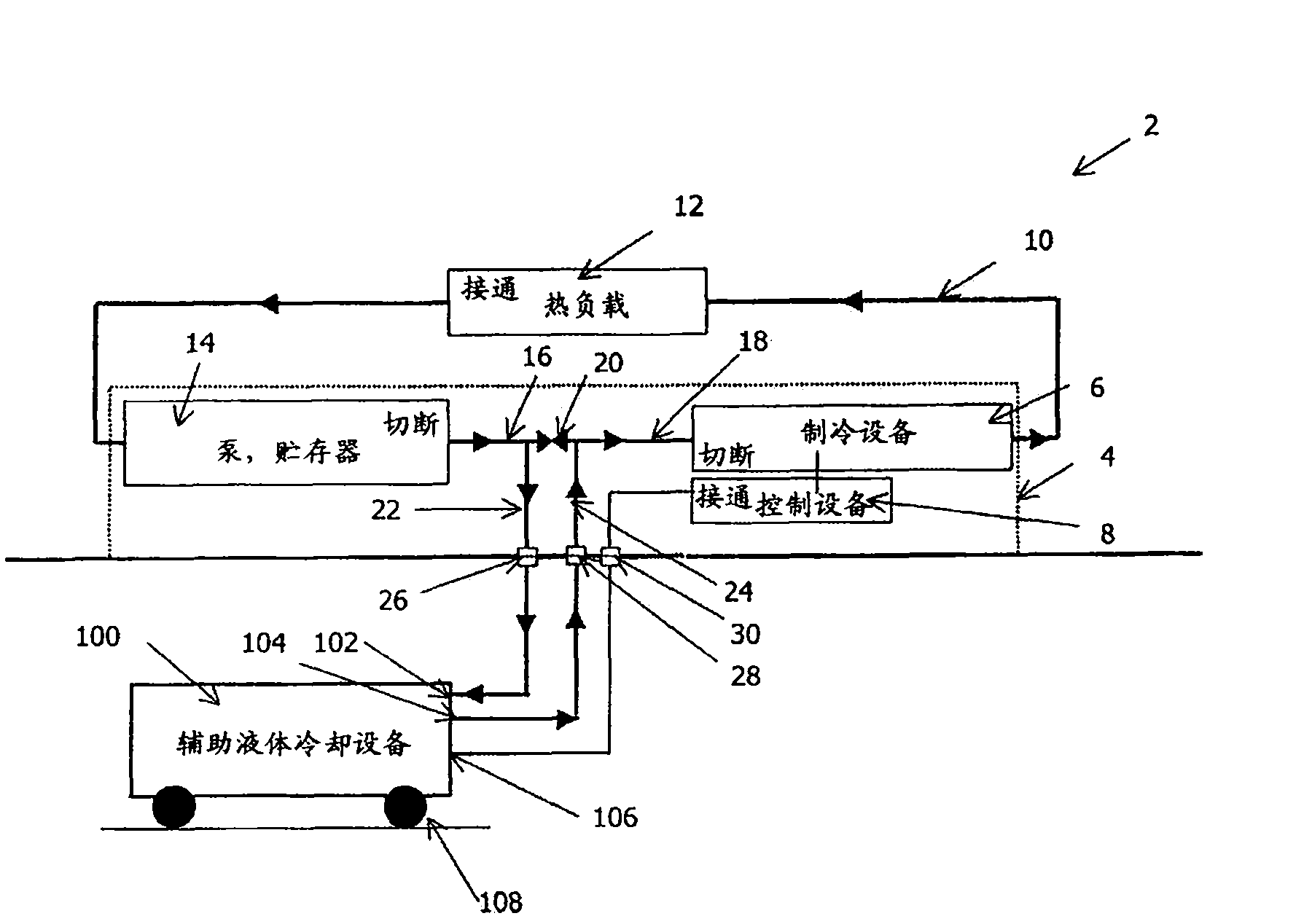

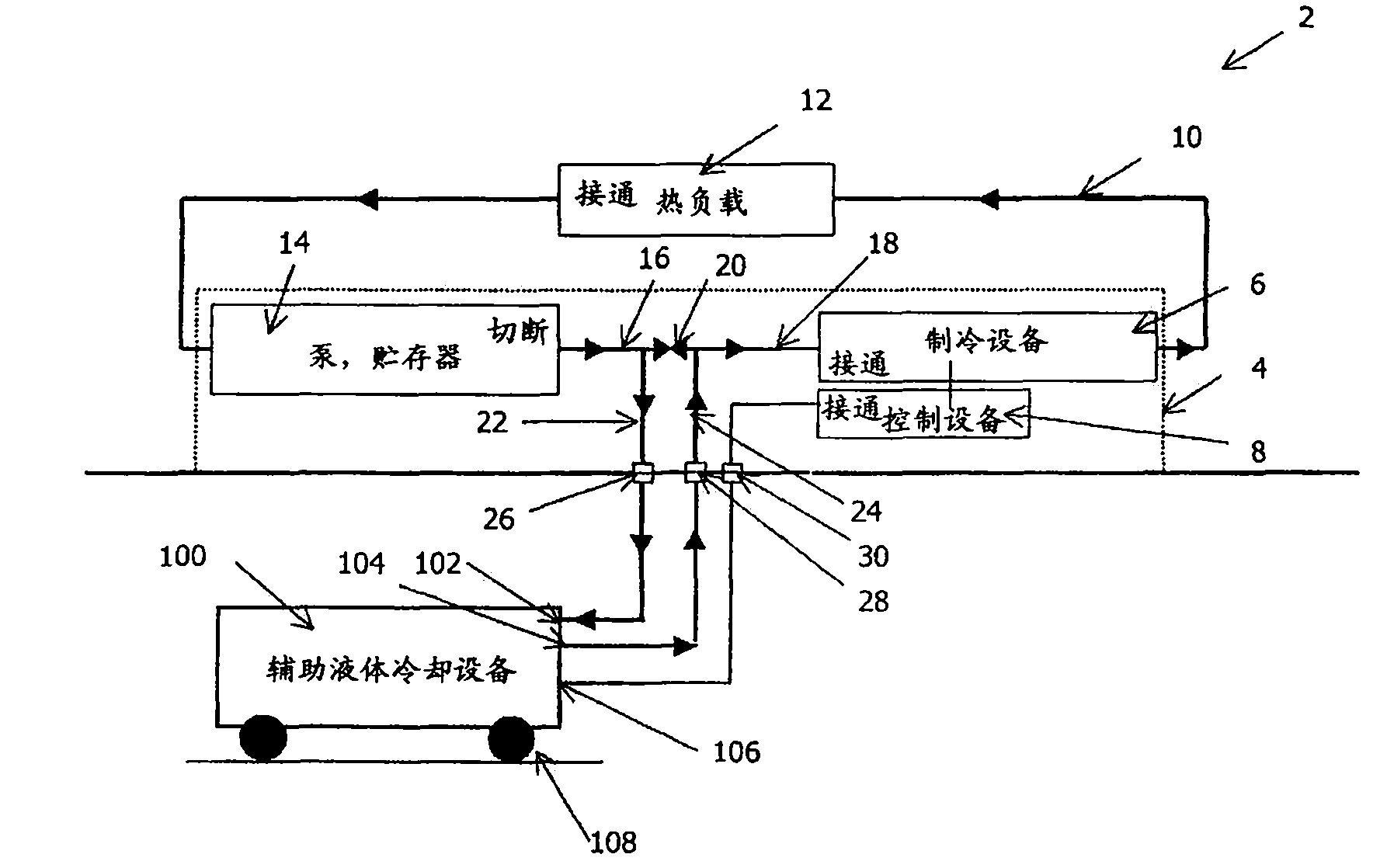

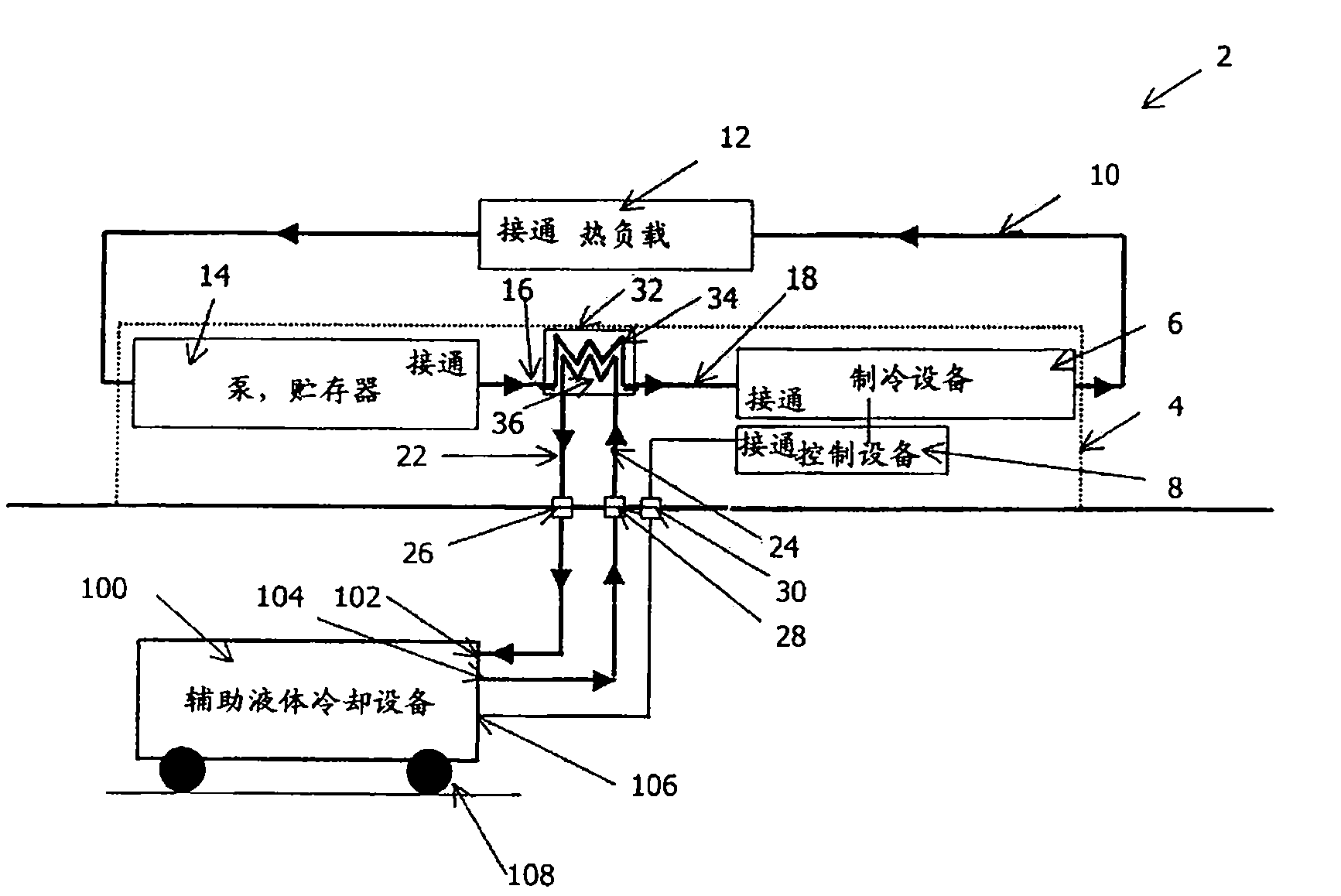

[0031] figure 1 An aircraft liquid cooling system 4 in an aircraft 2 is shown together with an auxiliary cooling device 100 . The aircraft liquid cooling system 4 comprises a refrigeration device 6 , a control device 8 , a pump and reservoir 14 , a first line 18 , a second line 16 and a first valve 20 . In flight, the refrigeration device 6 cools the liquid coolant delivered to the line 10 . The liquid coolant cools the heat load 12 . A pump 14 supplies coolant through the cooling circuit. Reservoir 14 provides additional coolant in the event of a leak. Since the first valve 20 between the first line 16 and the second line 18 is opened in flight, liquid coolant circulates in the cooling circuit.

[0032] The heat loads 12 may be food carts in the galley, food or drink areas in the galley, flight control computers, entertainment systems, and / or cabin areas to be individually air-conditioned. The cabin area to be individually air-conditioned may be first class and / or the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com