Special ecological blended yarn made of natural multicolour cotton-flax and preparation method thereof

A technology of blended yarn and ring spinning, applied in yarn, biochemical fiber processing, textile and papermaking, etc., can solve the problems of harmful human chemical residues, environmental pollution, etc., to reduce the cost of degumming, reduce environmental pollution, take good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

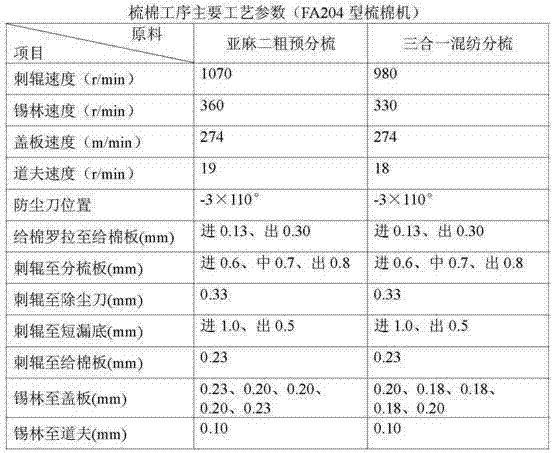

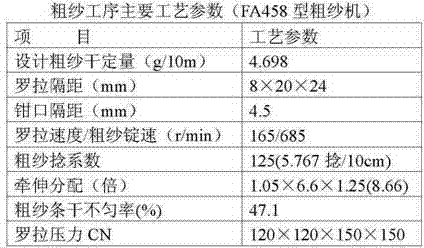

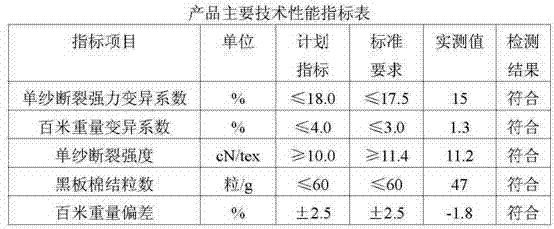

[0069] In this embodiment, the flax di-crude fiber content is controlled at 38%, and the cotton fiber content is controlled at 62%, wherein: the natural colored cotton fiber (dark brown) is controlled at 30% to ensure the degree of luster. Natural colored cotton, linen two-coarse and white cotton are ring spun according to the following steps:

[0070] (1) Second rough pretreatment of flax, i.e. flax opening and pre-carding process

[0071] The process flow is: artificial anesthesia → mist spraying emulsified oil and biological enzyme preparations → numbing → GM-210B bomb cleaning machine to open the hemp → GM-210B bomb cleaning machine for the second time to open the numb → the second numbing → A002D type disc bale grabbing machine→A035B type mixed cotton opener→FA106B type cotton opener→FA046 type vibrating cotton box feeder→A076E type single hand lapping machine→FA204 type carding machine→the third sacking.

[0072] A total of 24 hours for three times of numbness, each tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com