Gas drainage system and method for hyposmosis soft coal seams

A technology for soft coal seam and gas extraction, which is applied in the directions of gas discharge, drilling equipment and methods, and production fluids, etc., can solve the problems of inability to develop a fracture system, unsatisfactory drainage effect, and unsatisfactory drainage effect, etc. Improve the drainage effect, improve the gas drainage effect, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

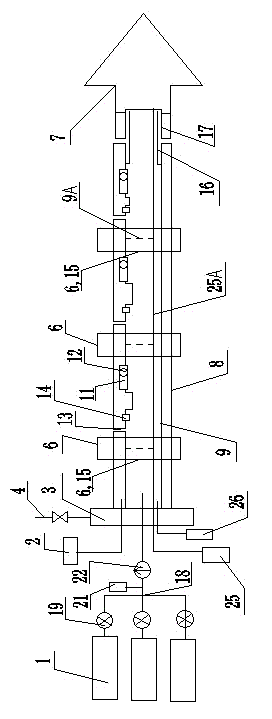

[0015] Such as figure 1 As shown, the low-permeability, soft coal seam gas extraction system of the present invention includes a power device mechanism, a drilling pressure-extraction integration mechanism and a metering mechanism.

[0016] The power device mechanism includes an air compressor 1 and an air drill 2 and is used to provide power for the integrated drilling, pressing and pumping mechanism.

[0017] The drilling pressure-pumping integrated mechanism includes a rotating blowout preventer 3, a blowout pipeline 4 (the function of the blowout pipeline 4 is to blowout when the pressure reaches the set value), drill pipe, and a multi-stage packer 6 ( There are at least two packers 6 (in practice, three to eight are evenly arranged along the length of the drill pipe, which can play the role of sealing the coal hole), inner drill pipe connector 15, electric motor 25, power motor and automatic variable diameter expansion Hole three-wing drill bit 7 (BZ-II type automatic va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com