Spent fuel pool cooling pump for nuclear power station

A technology for a spent fuel pool and a cooling pump, which is applied to liquid fuel engines, components of a pumping device for elastic fluids, pumps, etc., can solve the problems of large volume, poor shock resistance, and inconvenient maintenance, and achieves a solution to the problem of large volume. , to ensure the mechanical properties, the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

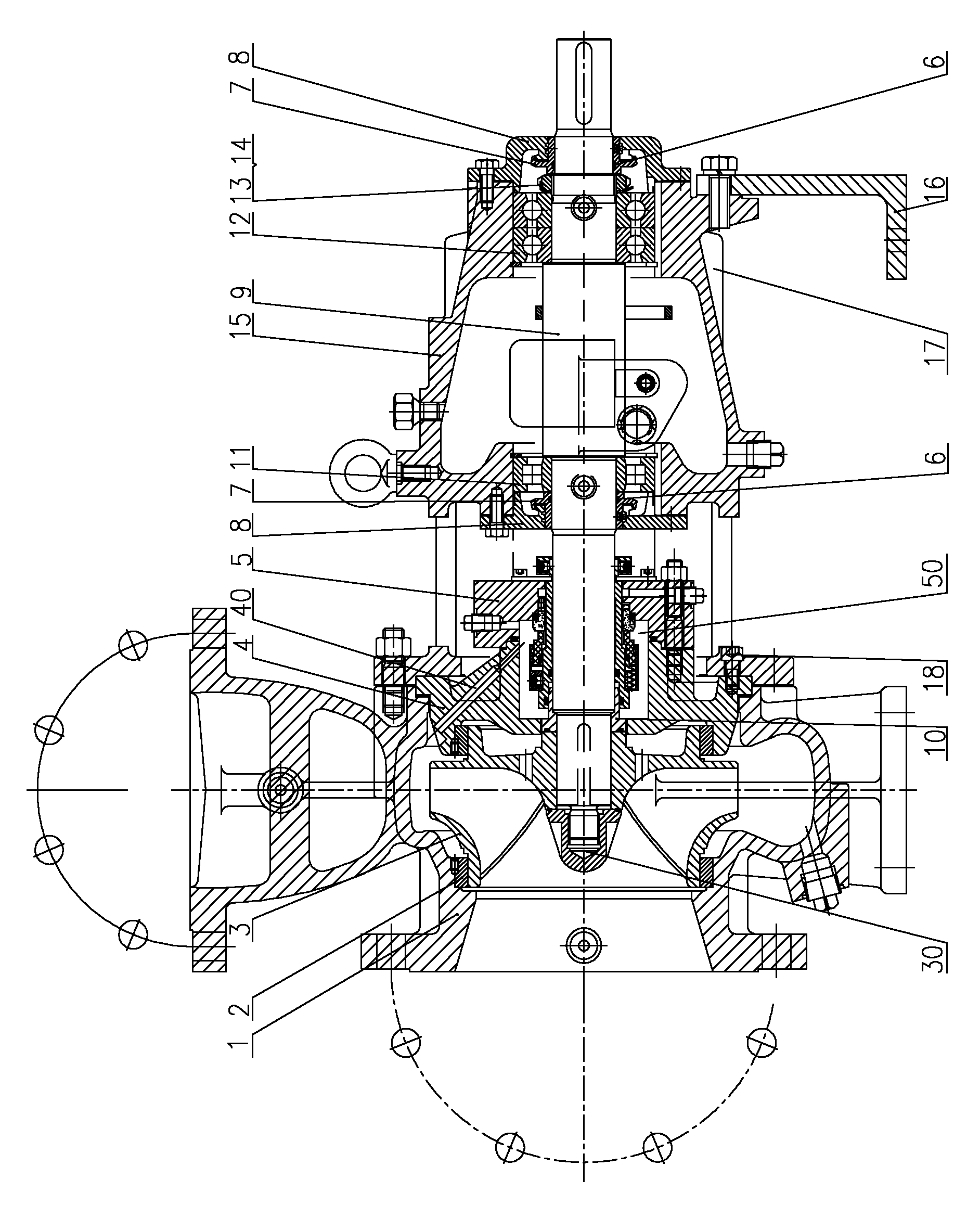

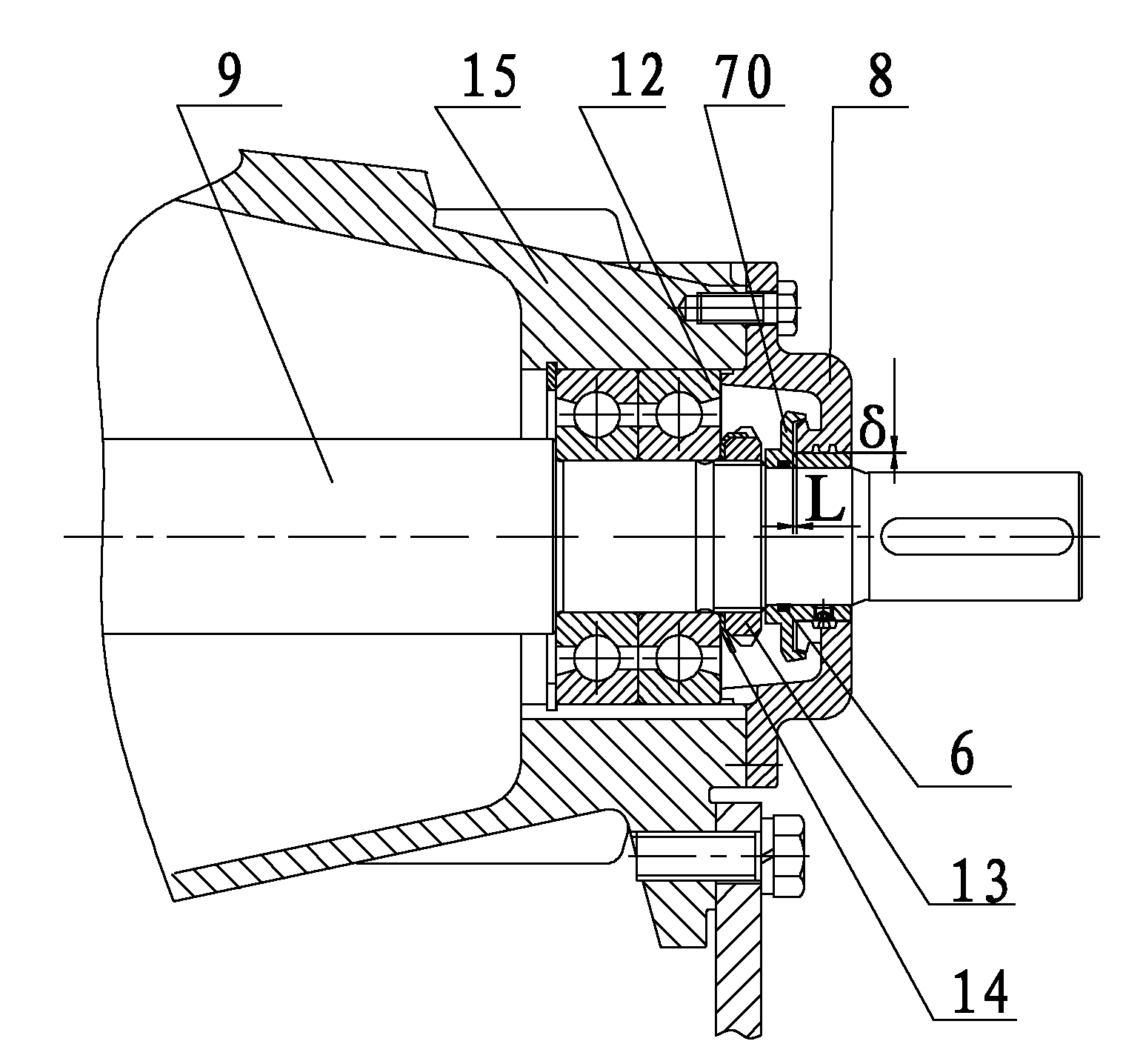

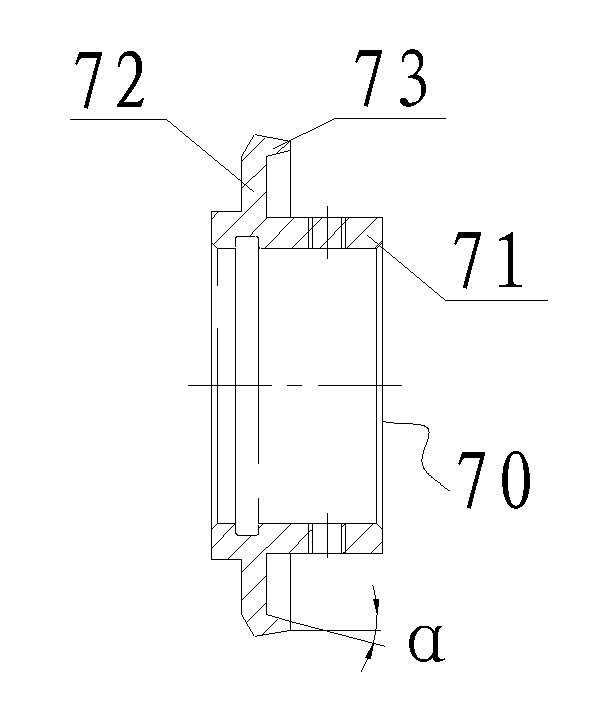

[0025] see figure 1 The spent fuel pool cooling pump for nuclear power plants of the present invention is a single-stage single-suction horizontal cantilever pump, which includes a stator assembly, a rotor assembly, a bearing assembly and a shaft seal assembly. The stator assembly includes a pump body 1, a pump cover 4 with a mechanical seal chamber and a pump body seal ring 2; the rotor assembly includes a pump shaft 9, an impeller 3, an impeller nut 30 and a shaft sleeve 10; the bearing assembly includes A bearing body 15 , bearings, a pair of bearing end covers 8 and a bearing bracket 16 ; the shaft seal assembly includes a bearing oil seal device 7 and a mechanical seal device 5 . in:

[0026] The pump body 1 is a radially split double volute structure, the suction port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com