Method for inspecting gas tightness of argon pipelines of molten steel tank

A technology of argon gas tube and molten steel tank, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc. High, easy to observe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

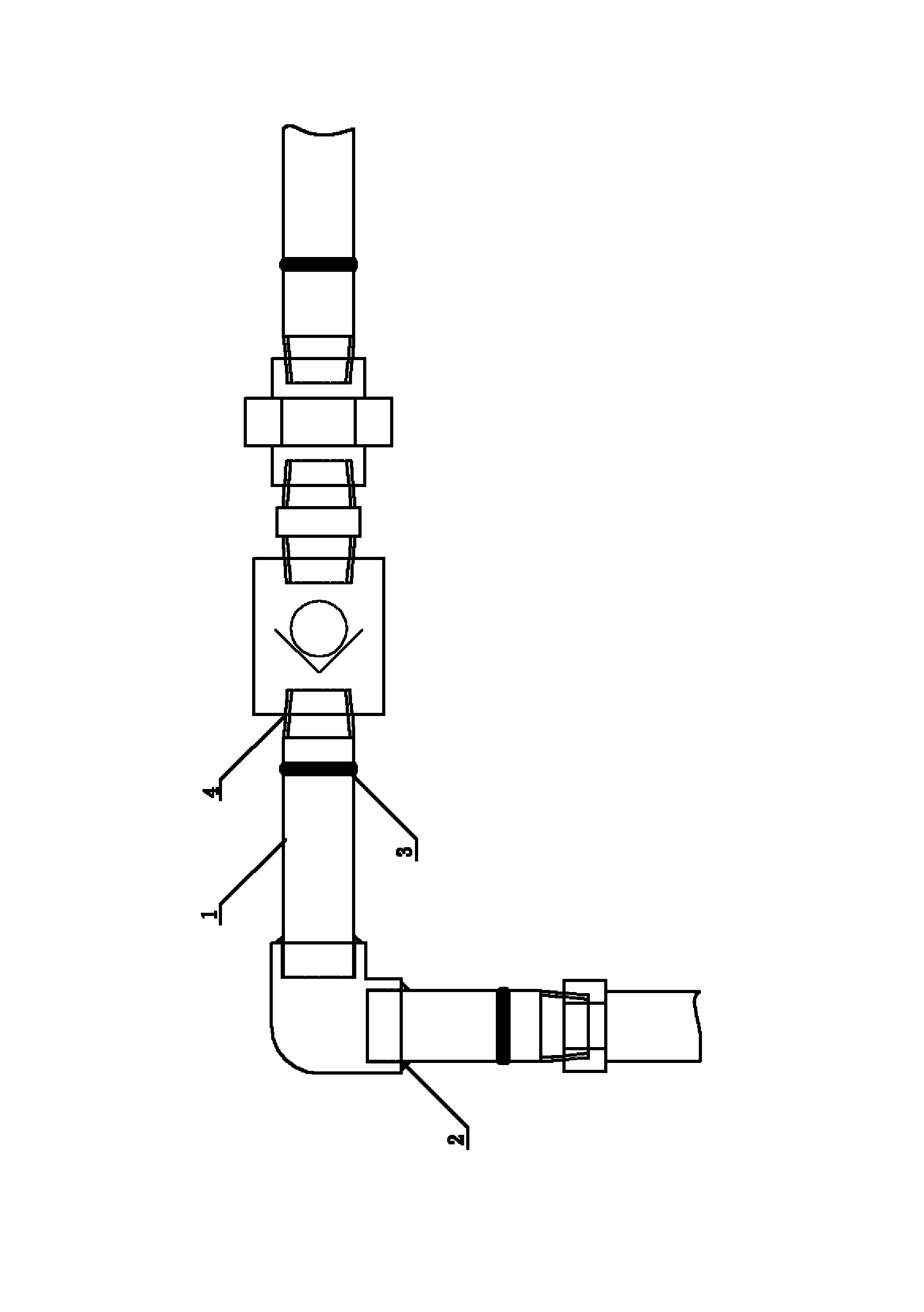

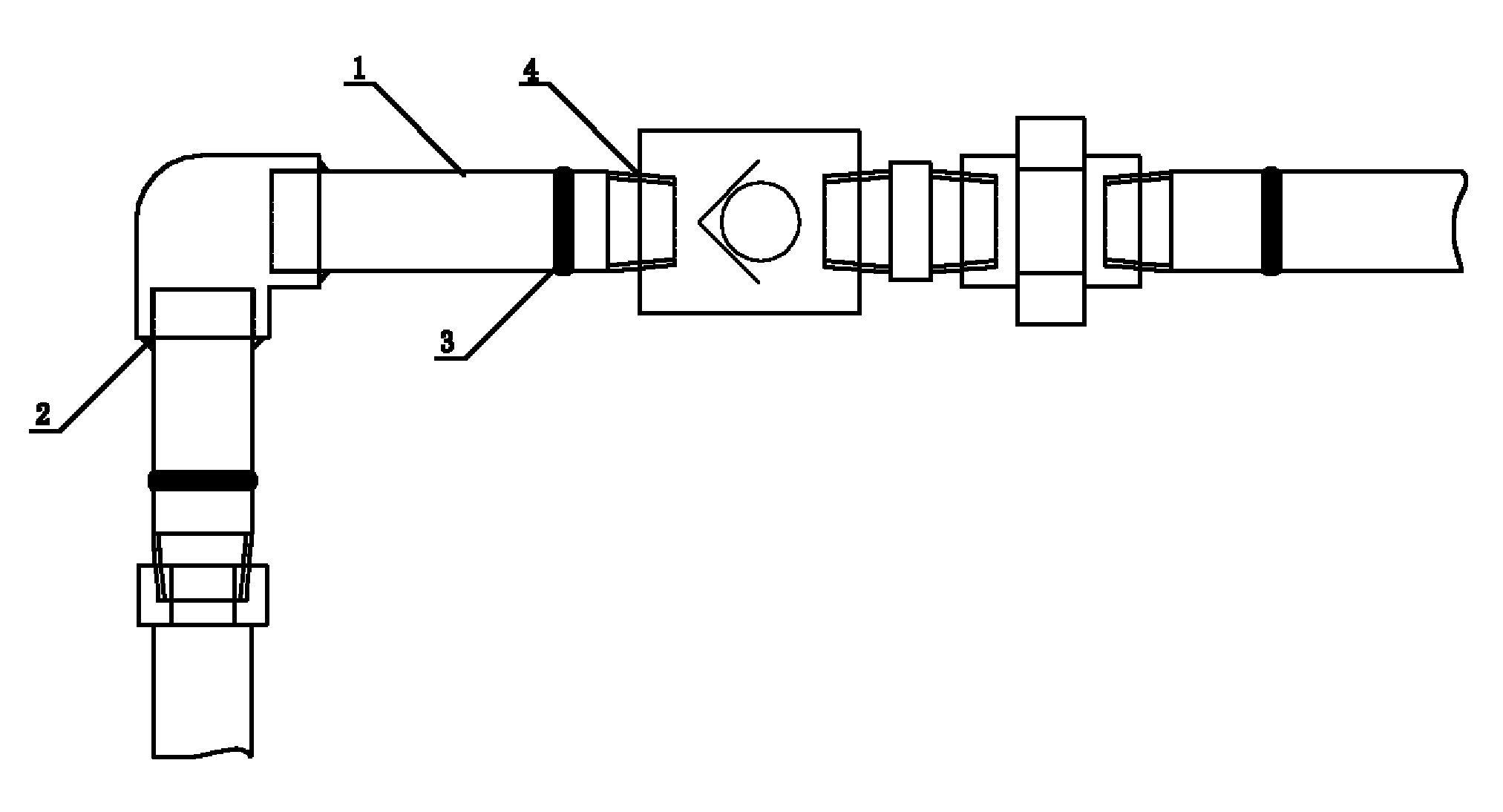

[0009] figure 1 Among them, 1 is the steel pipe, 2 is the fillet weld, 3 is the butt weld, and 4 is the threaded joint, among which 2, 3, and 4 are the air tightness inspection parts of the pipeline.

[0010] The following is a detailed description of the inspection process:

[0011] Air pressure test: in the part to be tested of the argon pipeline of the molten steel tank, such as figure 1 Apply clear water to 2, 3, and 4 of the test, and then apply purple litmus reagent to the area to be tested, and then inject high-pressure CO with a concentration ≥ 90% into the pipeline. 2 Gas, if the purple litmus reagent is found to turn red, it can be judged that the airtightness here is poor, which is because the high concentration of carbon dioxide gas escaping here reacts with water to produce carbonic acid, which turns the litmus red.

[0012] Hydrostatic test: in the part to be tested of the argon pipeline of the molten steel tank, such as figure 1 Apply purple litmus reagent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com