Novel cone lens generating single bottle beam

A technology of localized hollow beam and cone lens, applied in lens, optics, optical components, etc., can solve the problems of limited bottle intensity and low damage resistance threshold, and achieve easy component processing, high conversion efficiency, and high light damage threshold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure and principle of the novel axicon lens of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

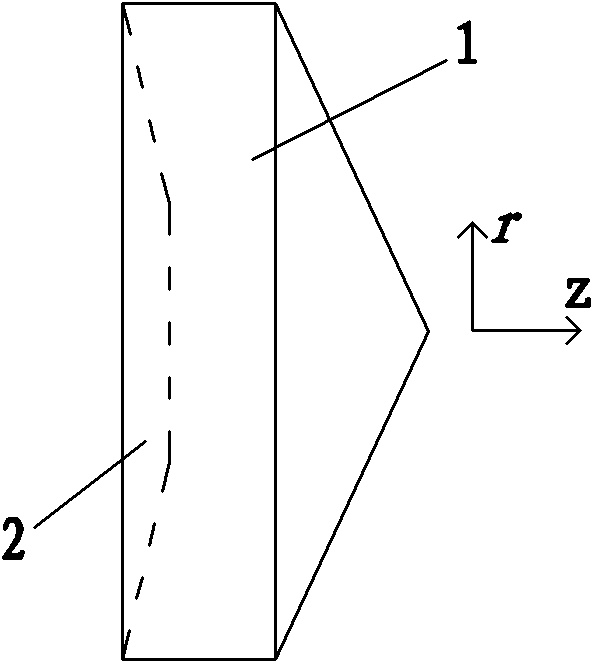

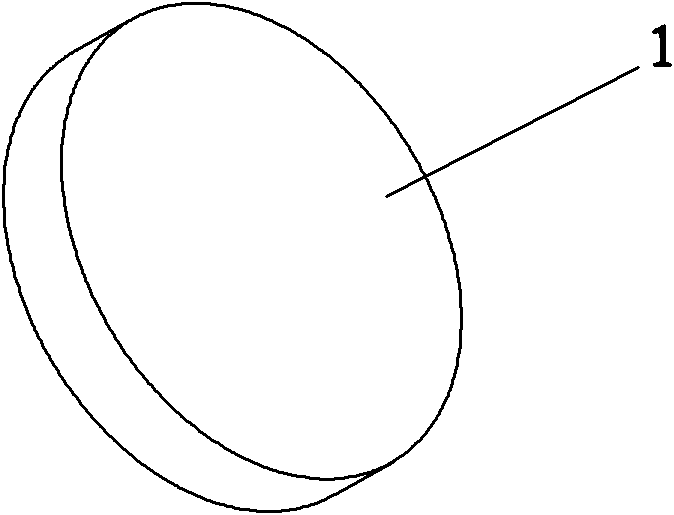

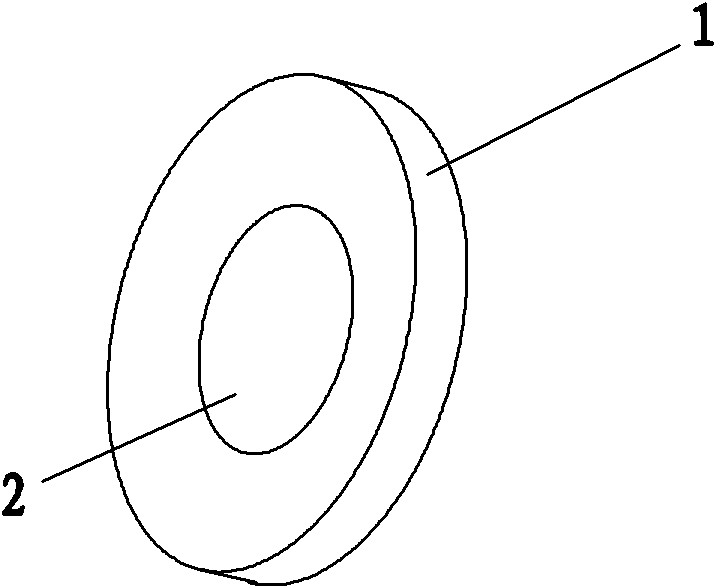

[0016] Such as Figure 1-3 Shown is a novel axicon lens that produces a single localized hollow beam of the present invention, which is an axicon 1 made of common optical glass materials, and a concave circular frustum is formed at the bottom of the axicon 1 by grinding structure 2, and the base angle of the frustum structure 2 is smaller than the base angle of the axicon 1.

[0017] As a preferred embodiment of the present invention, such as Figure 4 As shown, the peripheral radius of the frustoconical structure 2 is equal to the radius of the base of the axicon 1; wherein, the radius of the base of the axicon is set to be R 1 , the base angle is γ 1 , the outer radius of the frustum 2 is R 1 , the radius of the inner bottom surface is R 2 , the base angle is γ 2 , and γ 2 1 . Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com