Infrared focal plane detector packaging window and manufacturing method thereof

An infrared focal plane and detector technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as easy air leakage of detectors, poor vacuum performance, and reduced packaging yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

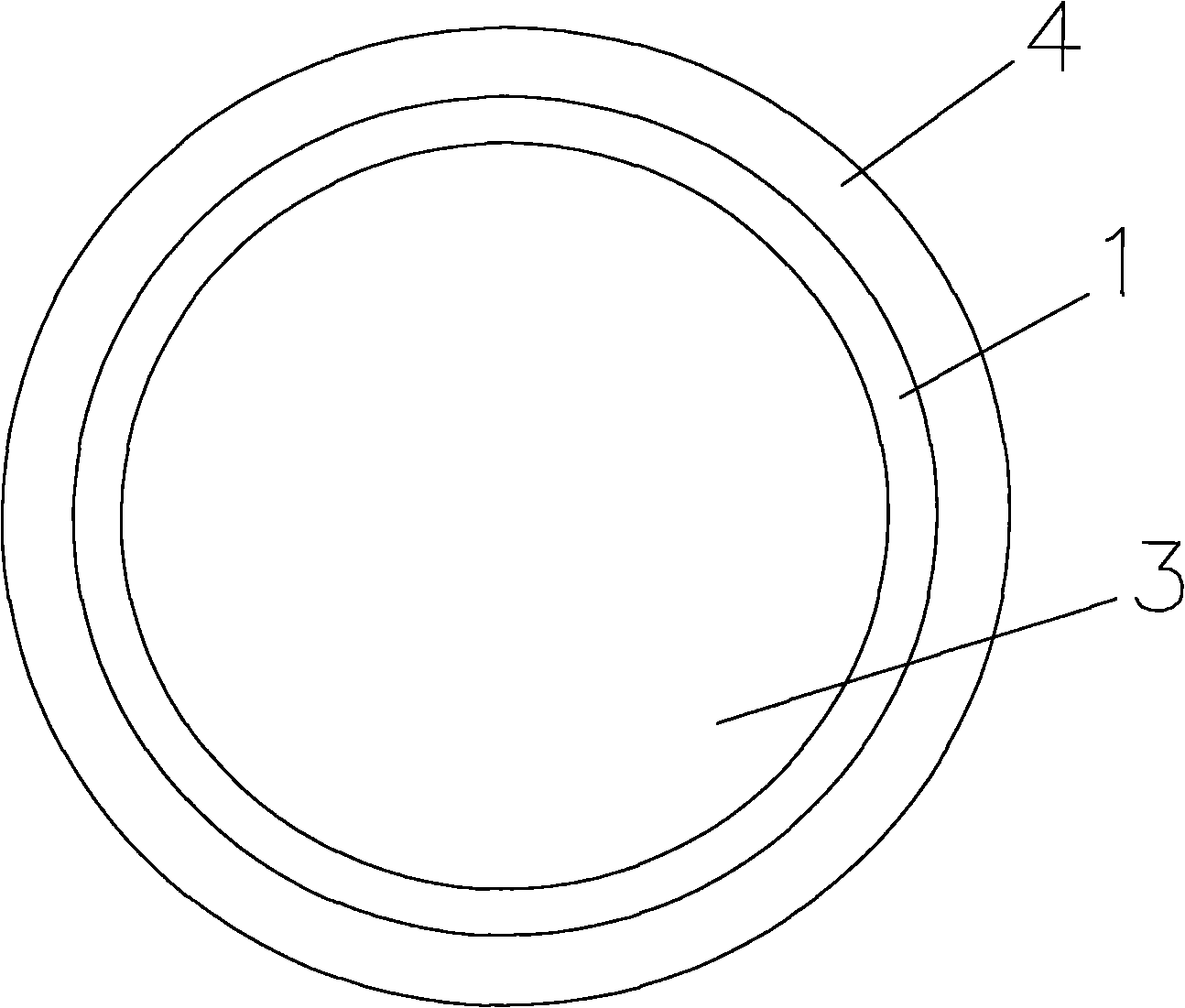

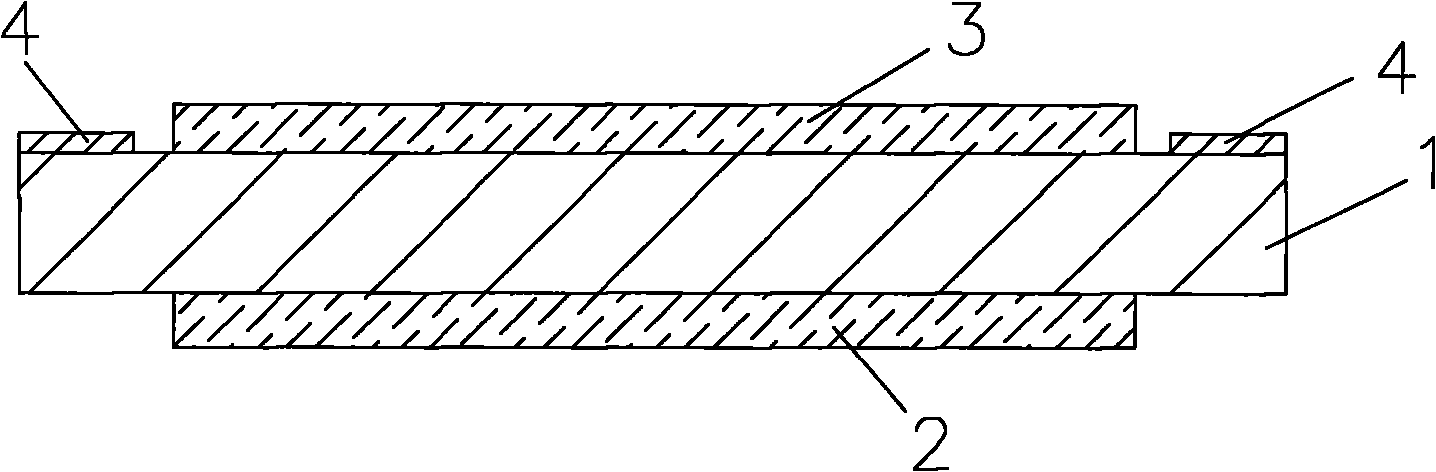

[0045] According to the above-mentioned manufacturing method, a 7.0um cut-off infrared focal plane detector packaging window for thermal imaging cameras was manufactured.

[0046] The substrate material is Si, the infrared thin film material is Ge and ZnS, and the metal welding layer material is Cr, Ni, Au.

[0047] The infrared optical film structure on the back is 1Sm-1.256L-2.951H-2.452L-2.752H2.274L-2.186H-2.407L-2.758H-2.612L-2.867H-2.153L-2.201H-2.693L-3.038H- 2.591L-4.714H-2.66L-3.432H-3.525L-4.319H-2.382L-3.861H-4.085L-3.257H-2.134L-5.305H-6.288L, where Sm represents Si substrate, H represents Ge, L stands for ZnS, and the data are in optical units.

[0048] The front optical film structure is 1Sm-1.198H-0.783L-1.362H-0.796L-1.46H0.859L-0.982H-1.247L-1.003H-1.307L-0.684H-1.128L-1.064H-1.137L-1.237 H-1.307L-1.682H-1.148L-1.815H-1.072L-1.162H-1.84L-1.446H-1.49L-1.261H-1.65L-1.516H-1.257L-1.996H-1.655L-1.901H- 2.084L-2.144H-1.633L-2.195H-1.727L-2.381H-2.36L-1.053H-2.65...

Embodiment 2

[0052] According to the above manufacturing method, a 8.5-12um transparent infrared focal plane detector packaging window is manufactured.

[0053] The substrate material is Ge, the infrared thin film material is PbTe and ZnSe, and the metal welding layer material is Ti, Ni, Au.

[0054]The infrared optical film structure on the back is 1Sm-0.478L-1.041H-0.994L-1.101H-1.006L-1.004H-0.972L-1.342H-0.971L-0.971H-1.011L-1.006H-0.561L-0.811L -1.023H-1.447L-1.732H-1.434L-1.624H-1.577L-1.033H-1.542L-1.81H-1.359L-2.209H-0.983L-1.133L-1.595H-1.818L-2.618H-1.608 L-1.611H-2.375L-2.352H-0.649L-3.551H-3.7L. Among them, Sm represents Ge substrate, H represents PbTe, L represents ZnSe, and the data are in optical units.

[0055] The front optical film structure is 1Sm-1.389H-0.122L-1.393H-1.121L-1.043H-1.051L-1.027H-1.038L-1.023H-1.034L-1.021H-1.032L-1.022H-1.033L- 1.023H-1.035L-1.027H-1.043L-1.04H-1.075L-1.02H-0.518L. Among them, Sm represents Ge substrate, H represents PbTe, L represen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com