MEMS microphone and encapsulation method thereof

A packaging method and technology for microphones, which are applied to sensors, electrostatic transducers, microphones, electrical components, etc., can solve the problems of non-adhesion and firmness of conductive adhesives, deformation, and complicated manufacturing processes, and are conducive to large-scale production. The effect of promotion, simple bonding process and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

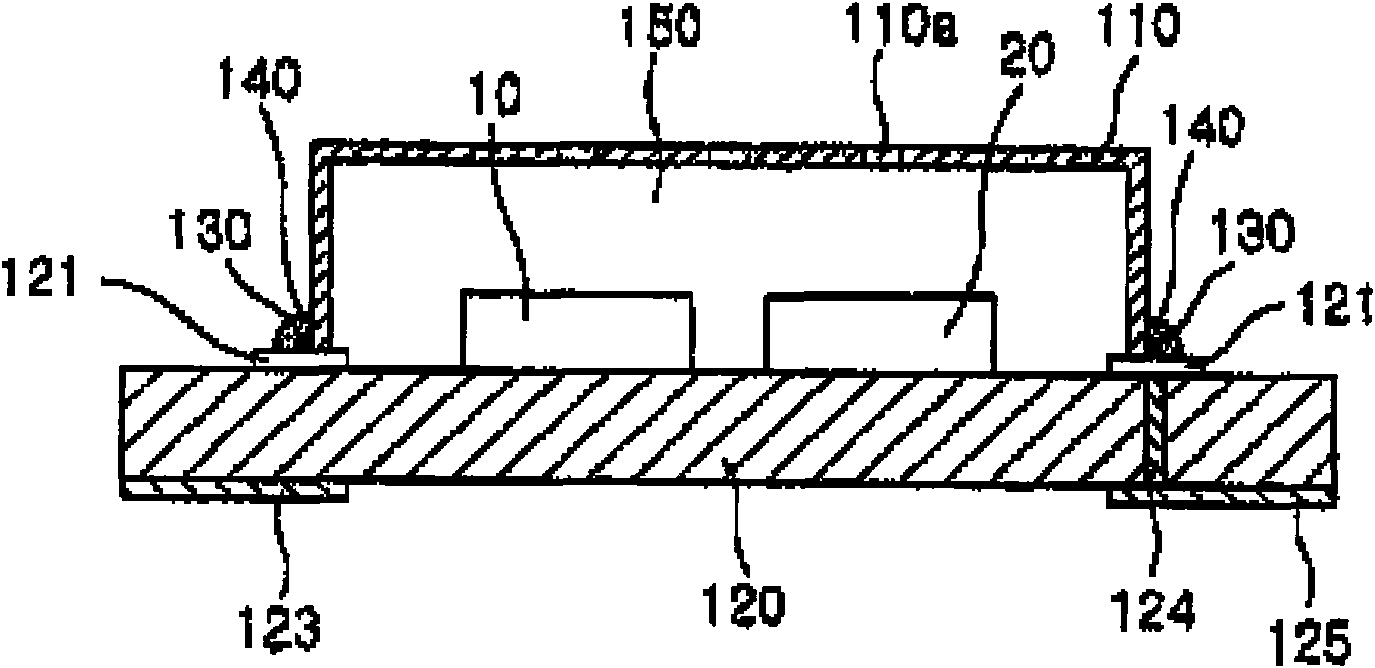

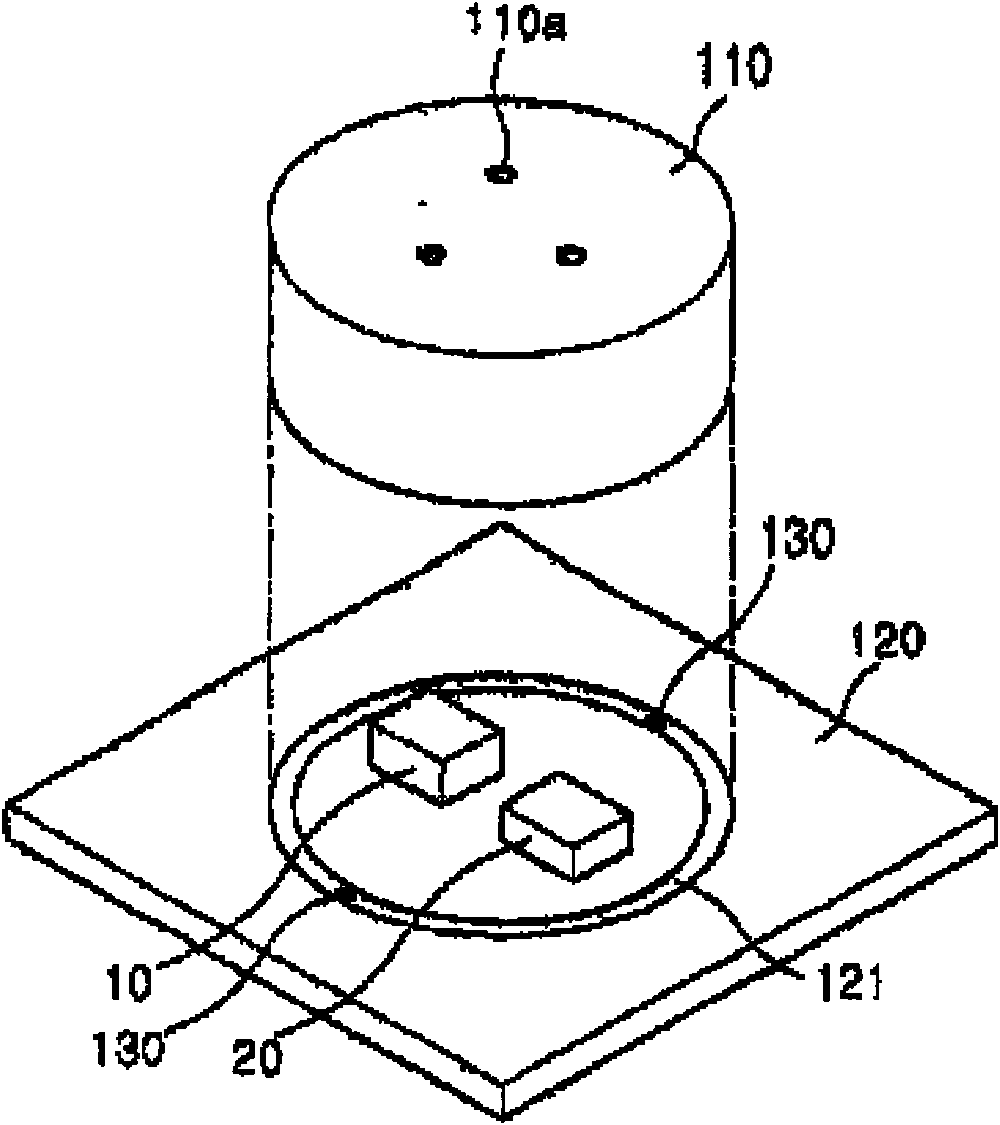

[0035] image 3 is a schematic diagram showing a specific structure of the MEMS microphone according to the first embodiment of the present invention. Such as image 3 As shown, the MEMS microphone that the present invention relates to comprises a square groove-shaped housing 1 and a square circuit board 3, and the open end 11 of the housing 1 and the square circuit board 3 are bonded together to form a square cavity of the MEMS microphone. A MEMS acoustic chip 2 for converting sound signals into electrical signals and an ASIC 4 for amplifying electrical signals are arranged in the cavity. The shell 1 is provided with a sound hole 5 for receiving external sound signals. And: the position on the circuit board 3 combined with the opening end 11 of the housing 1 is provided with a grounded annular conductive layer 31, the surface of the opening end 11 of the housing is set as an annular conductive surface, between the circuit board 3 and the opening end 11 of the housing 1 An ...

no. 2 example

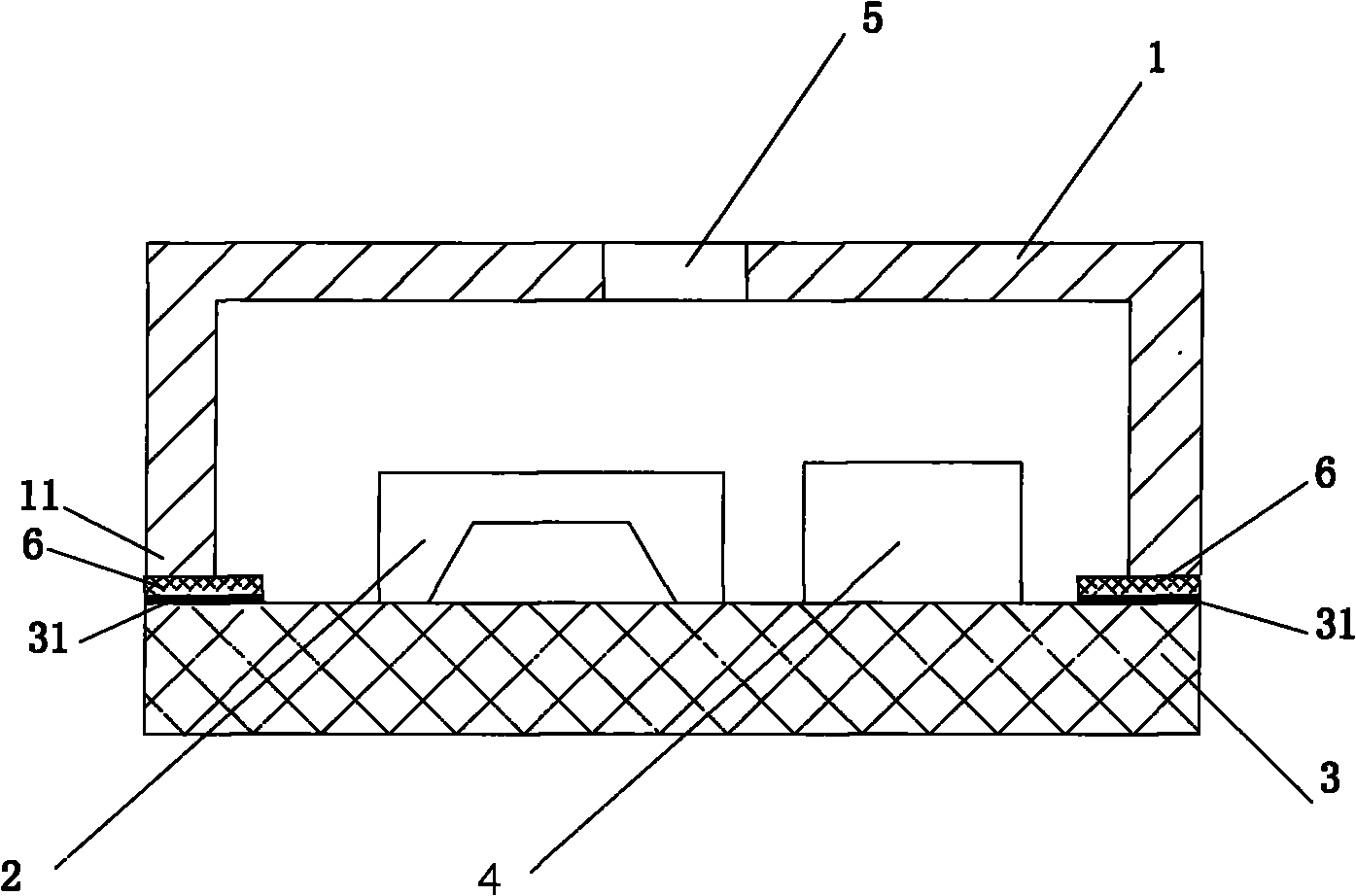

[0044] Figure 5 is a schematic diagram showing a specific structure of the MEMS microphone according to the second embodiment of the present invention. Such as Figure 5 As shown, the MEMS microphone includes a slot-shaped housing 1 and a circuit board 3, the open end 11 of the housing 1 and the circuit board 3 are bonded together to form the cavity of the MEMS microphone, and a sound signal conversion function is provided in the cavity. A MEMS acoustic chip 2 for electrical signals and an ASIC 4 for amplifying electrical signals. The shell 1 is provided with a sound hole 5 for receiving external sound signals. And: the position where the circuit board 3 is combined with the opening end 11 of the housing 1 is provided with a grounded annular conductive layer 31, the surface of the opening end 11 of the housing is set as an annular conductive surface, and the circuit board 3 and the opening end 11 of the housing 1 are arranged between There is an annular insulating adhesive g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com