Plastic-metal binder and preparation method thereof

A metal bonding and plastic technology, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of low bonding strength, pulling apart, weak bonding, etc. The effect of simple process, good stability and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

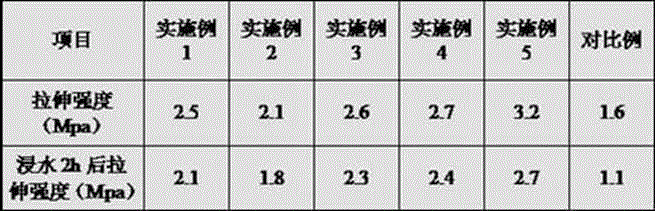

Examples

Embodiment 1

[0021] A preparation method of a plastic-metal adhesive, the preparation steps are as follows:

[0022] Weigh each raw material according to parts by weight, specifically: 60 parts of epoxy resin, 30 parts of phenolic resin, 6 parts of isocyanate, 1 part of chromium powder, 2 parts of cobalt powder, 10 parts of dibutyl maleate, Tween 601 parts, 3 parts of calcium stearate, 2 parts of sodium chloride, 6 parts of polyoxymethylene dimethyl ether, 4~10 parts of polyoxymethylene, 2 parts of sodium silicate, 13 parts of o-cresyl glycidyl ether, curing agent 15 parts, 22 parts of acetone and 30 parts of butyl acetate; The curing agent is the composite of trimethylhexamethylenediamine and bisbenzylamino ether in a weight ratio of 0.5:1;

[0023] Add epoxy resin, phenolic resin, dibutyl maleate, o-cresyl glycidyl ether, polyoxymethylene dimethyl ether, polyoxymethylene and butyl acetate in the container, and heat Stir at high temperature to obtain mixture A;

[0024] Add chromium pow...

Embodiment 2

[0027] A preparation method of a plastic-metal adhesive, the preparation steps are as follows:

[0028] Weigh each raw material according to parts by weight, specifically: 75 parts of epoxy resin, 48 parts of phenolic resin, 14 parts of isocyanate, 5 parts of chromium powder, 8 parts of cobalt powder, 18 parts of dibutyl maleate, Tween 606 parts, 10 parts of calcium stearate, 7 parts of sodium chloride, 11 parts of polyoxymethylene dimethyl ether, 4~10 parts of polyoxymethylene, 6 parts of sodium silicate, 28 parts of o-cresyl glycidyl ether, curing agent 25 parts, 40 parts of acetone and 50 parts of butyl acetate; The curing agent is the compound of trimethylhexamethylene diamine and bisbenzyl amino ether in a weight ratio of 2:3;

[0029] Add the epoxy resin, phenolic resin, dibutyl maleate, o-cresyl glycidyl ether, polyoxymethylene dimethyl ether, polyoxymethylene and butyl acetate in the container, at 50 ℃ Stir at high temperature to obtain mixture A;

[0030] Add chromi...

Embodiment 3

[0033] A preparation method of a plastic-metal adhesive, the preparation steps are as follows:

[0034] Weigh each raw material according to parts by weight, specifically: 67 parts of epoxy resin, 39 parts of phenolic resin, 10 parts of isocyanate, 3 parts of chromium powder, 5 parts of cobalt powder, 14 parts of dibutyl maleate, Tween 603 parts, 6 parts of calcium stearate, 5 parts of sodium chloride, 8 parts of polyoxymethylene dimethyl ether, 7 parts of polyoxymethylene, 4 parts of sodium silicate, 21 parts of o-cresyl glycidyl ether, 20 parts of curing agent , 31 parts of acetone and 40 parts of butyl acetate; Described curing agent is the composite of trimethylhexamethylene diamine and bisbenzyl amino ether by weight ratio of 1.2:2;

[0035] Add the epoxy resin, phenolic resin, dibutyl maleate, o-cresyl glycidyl ether, polyoxymethylene dimethyl ether, polyoxymethylene and butyl acetate in the container, at 35~50 Stirring at a temperature of °C to obtain a mixture A;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com