Special efficient turning tool for hogging ultra-large axial forgings

A super-large, waste machining technology, applied in the direction of tools for lathes, metal processing equipment, turning equipment, etc., can solve the problems of low tool service life, restricted production efficiency, tool breakage failure, etc., to improve processing efficiency, increase Effective heat dissipation area and the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

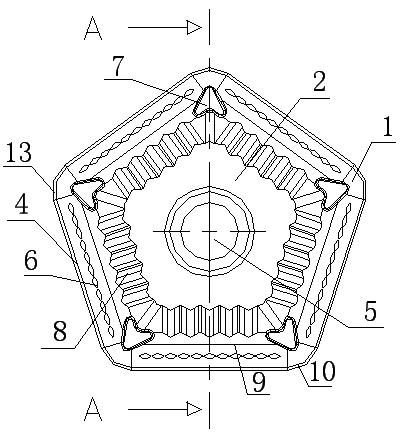

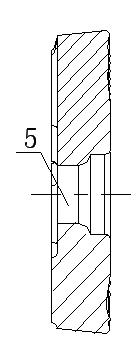

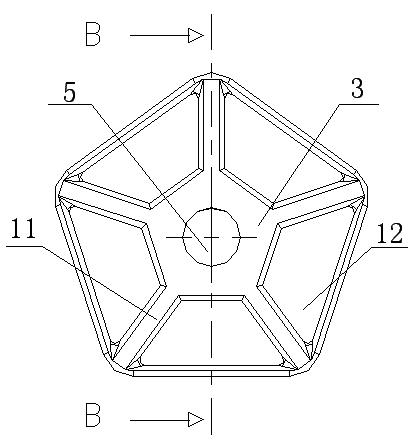

[0024] A special high-efficiency turning tool for super-large shaft forgings, which consists of: a turning tool body 1, the center of the turning tool body has a fastening screw hole 5, and the turning tool body is a regular pentagon with five a cutting edge, the turning tool body has a rake face 2 and a bottom surface 3, the turning tool body cutting surface 13 has a group of negative chamfer cutting edges 4, and the turning tool body rake face has in turn Ellipsoidal protrusions 6, arrow-shaped protrusions 7, wave-shaped chip guide walls 8, chip pockets 9, arc transition edges 10;

Embodiment 2

[0026] The special high-efficiency turning tool for machining super large shaft forgings described in Example 1, the cutting edge is linear, the thickness of the turning tool body is 9mm, and a relief angle of about 7°-9° is adopted, 6 °--A rake angle of about 7°, the edge inclination angle is 0°; the rake face has a three-dimensional chip breaker, and the chip pocket has an ellipsoidal protrusion near the cutting edge; the chip pocket The inner chip guide wall is a wave-shaped structure; the corner of the chip breaker, that is, the transition edge, has an arrow-shaped protrusion; the bottom of the turning tool body has a cooling groove; the turning tool body is connected with the The turning tool holder is fixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com