Controller and control method of eddy-current retarder of combined braking system

An eddy current retarder and combined braking technology, which is applied in electric braking systems, electric vehicles, transportation and packaging, etc., can solve troublesome operation, long working hours, and difficulty in reaching the working temperature of main brake contact wear and contact parts and other issues to achieve the effect of reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

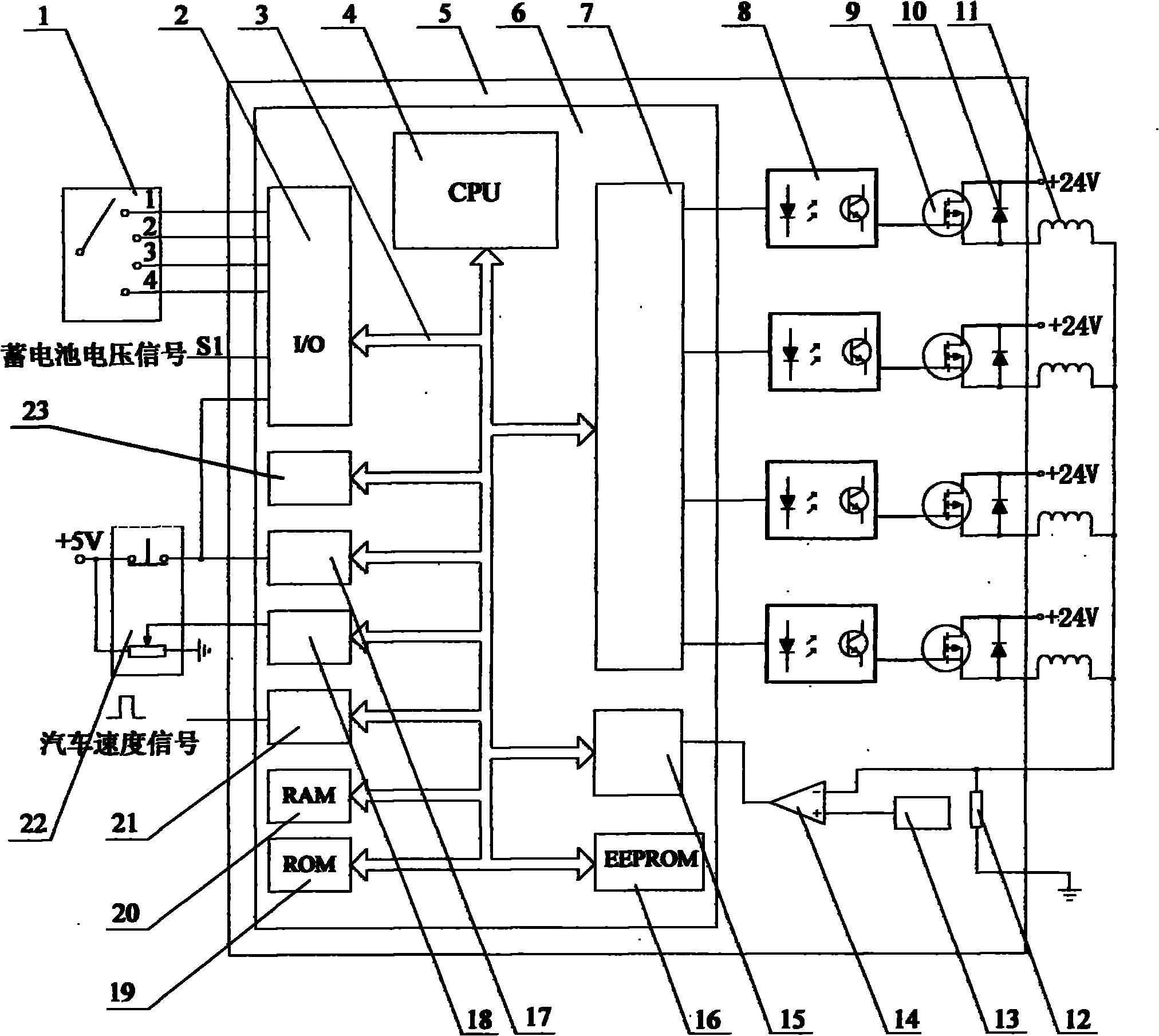

[0021] The following combination figure 1 Illustrate the joint control system eddy current retarder controller circuit structure of the present invention:

[0022] Such as figure 1 As shown, the combined braking system eddy current retarder controller is composed of a microcomputer 6, a high-power transistor drive circuit, a current feedback circuit, an eddy current retarder combination switch 1, and a brake pedal position sensor 22. Wherein microcomputer 6 comprises input / output port 2, internal bus 3, microcomputer CPU4, PWM control unit 7, No. 1 interrupt controller 15, No. 2 interrupt controller 17, electrically erasable programmable memory 16, modulus / digital Converter 18, read-only memory 19, random access memory 20, counter 21, timer 23, high-power transistor drive circuit includes optocoupler 8, insulated gate bipolar transistor 9, freewheeling diode 10, current feedback circuit includes sampling resistor 12, Precision voltage source 13, operational amplifier 14, edd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com