Temperature compensation current source having wide temperature scope and being compatible with CMOS (complementary metal-oxide-semiconductor transistor) technique

A temperature compensation and wide temperature technology, applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve the problems of small temperature range, large current source area, and high manufacturing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further describe the present invention below in conjunction with accompanying drawing.

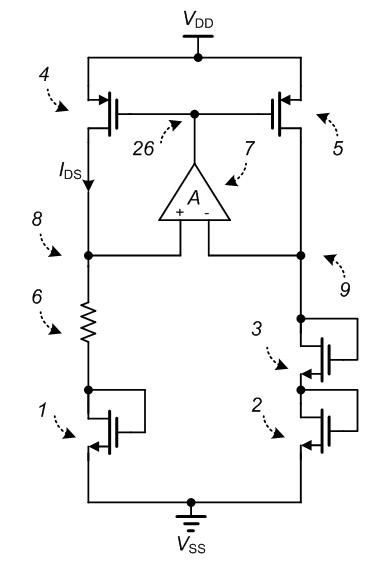

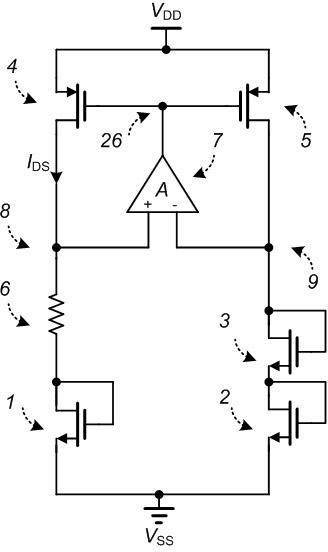

[0014] figure 1 A circuit implementation of the entire temperature compensated current source is shown. In the figure, the PMOS transistors 4 and 5 are connected in the form of a current mirror to ensure that the current of the two branches is twice the relationship, and the operational amplifier 7 has a high enough gain to make the voltages of the nodes 8 and 9 equal, that is, the resistance 6 and the NMOS The sum of the gate-source voltage of tube 1 is equal to the sum of the gate-source voltages of NMOS tubes 2 and 3. Through this equation relationship, the reference current source can realize temperature compensation by using different temperature coefficients of resistance, MOS tube mobility, and threshold voltage. , so as to obtain a reference current source with a lower temperature coefficient. Wherein, the sources of the PMOS transistors 4 and 5 are connected to the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com