Full-digital-frequency tracking inverting type electromagnetic induction heating power supply

An electromagnetic induction heating and frequency tracking technology, applied in induction heating, induction current source, induction heating control and other directions, can solve the problems of slow dynamic response, narrow frequency tracking range, poor reliability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

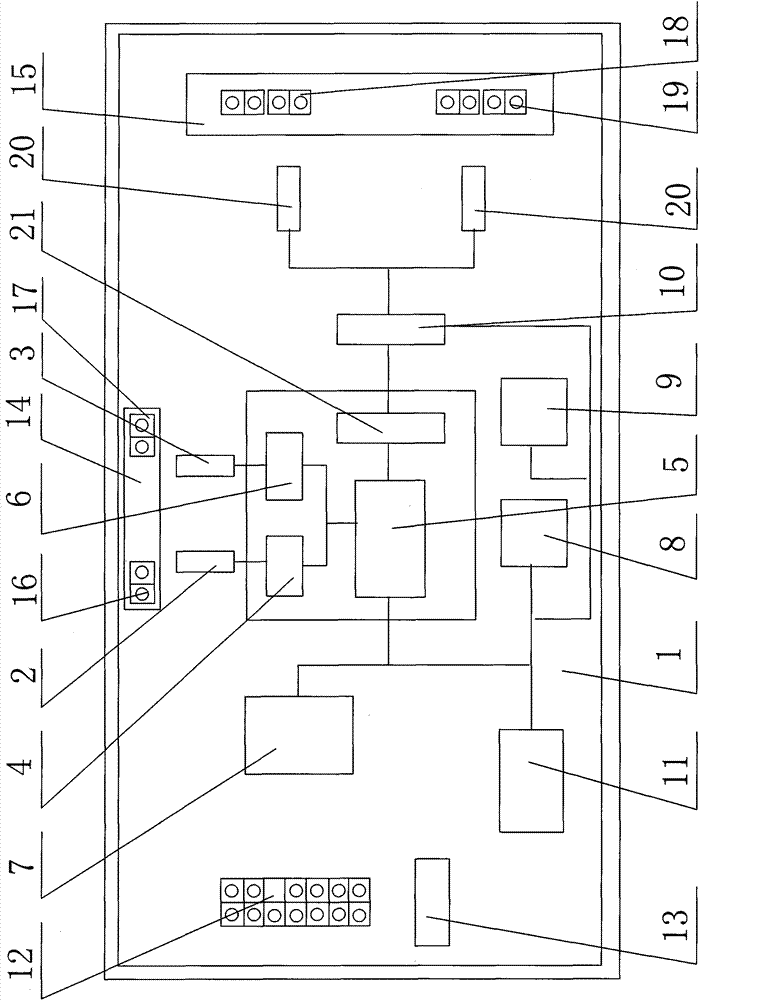

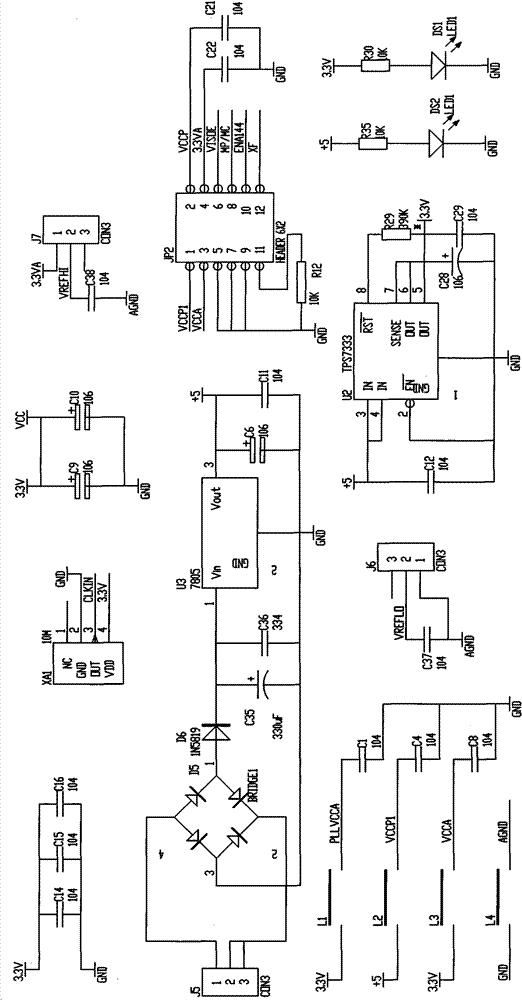

[0022] An all-digital frequency tracking inverter type electromagnetic induction heating power supply, which consists of: a substrate 1, on which a voltage feedback unit circuit 2 and a current feedback unit circuit 3 are installed, and the voltage feedback unit circuit 2 is converted by analog to digital ADC is connected to central processor unit circuit 5, and described current feedback unit circuit 3 is connected to central processor unit circuit 5 through phase lock 6, and described central processor unit circuit 5 is respectively connected to online test JTAG interface unit circuit 7, reset circuit 8. An oscillating OSC unit circuit 9 , a frequency tracking circuit 21 and a power unit circuit 11 , the frequency tracking circuit is connected to the buffer driving unit circuit 10 , and the buffer driving unit circuit 10 is connected to the isolation driving unit circuit 20 .

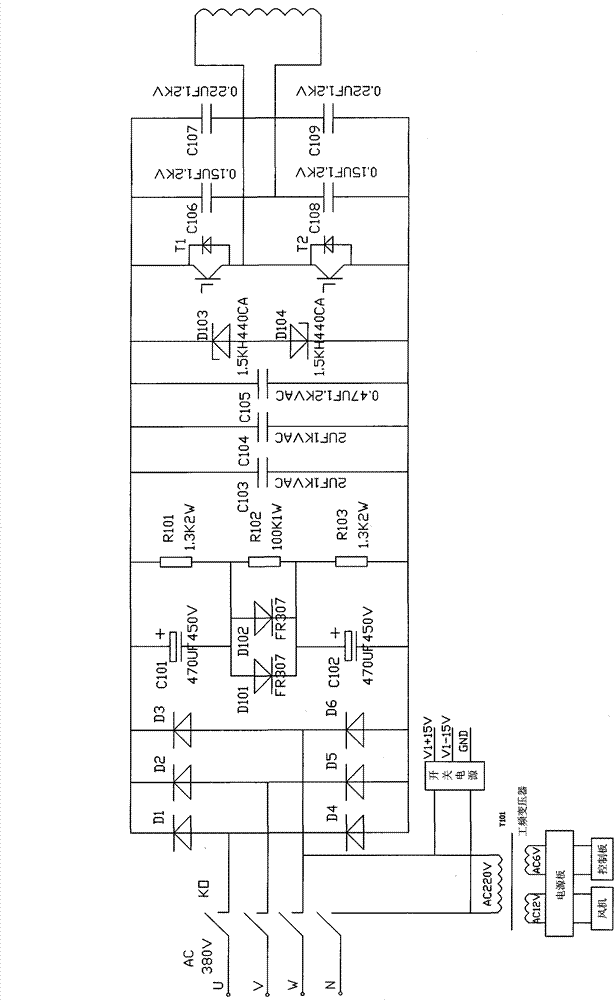

[0023] In the all-digital frequency tracking inverter type electromagnetic induction heating power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com