Vacuum cleaner and insert part of a vacuum cleaner

A technology for vacuum cleaners and inserts, applied in the directions of vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of high cost, laborious processing and assembly, etc., and achieve the effect of enhancing purposeful flow and avoiding eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

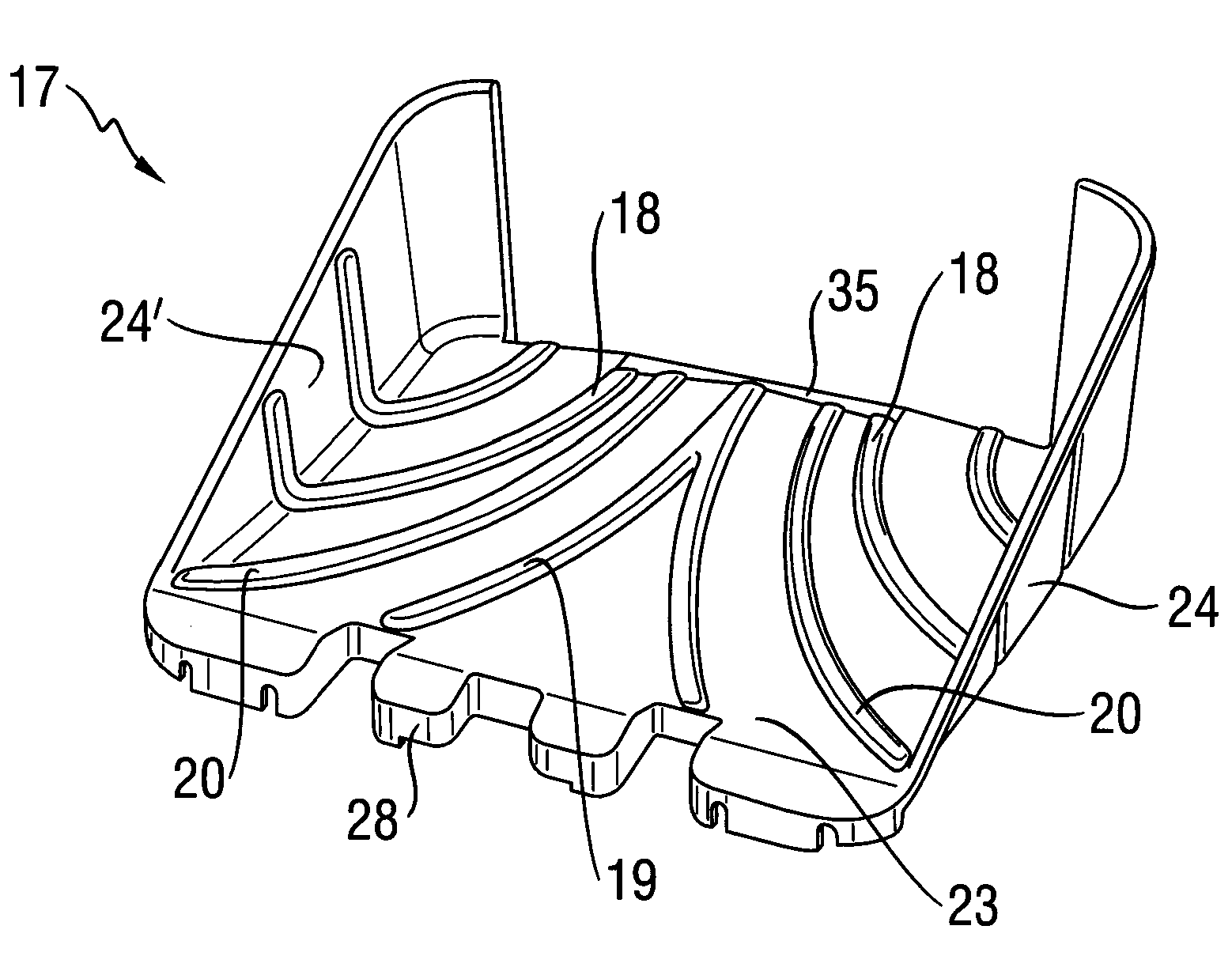

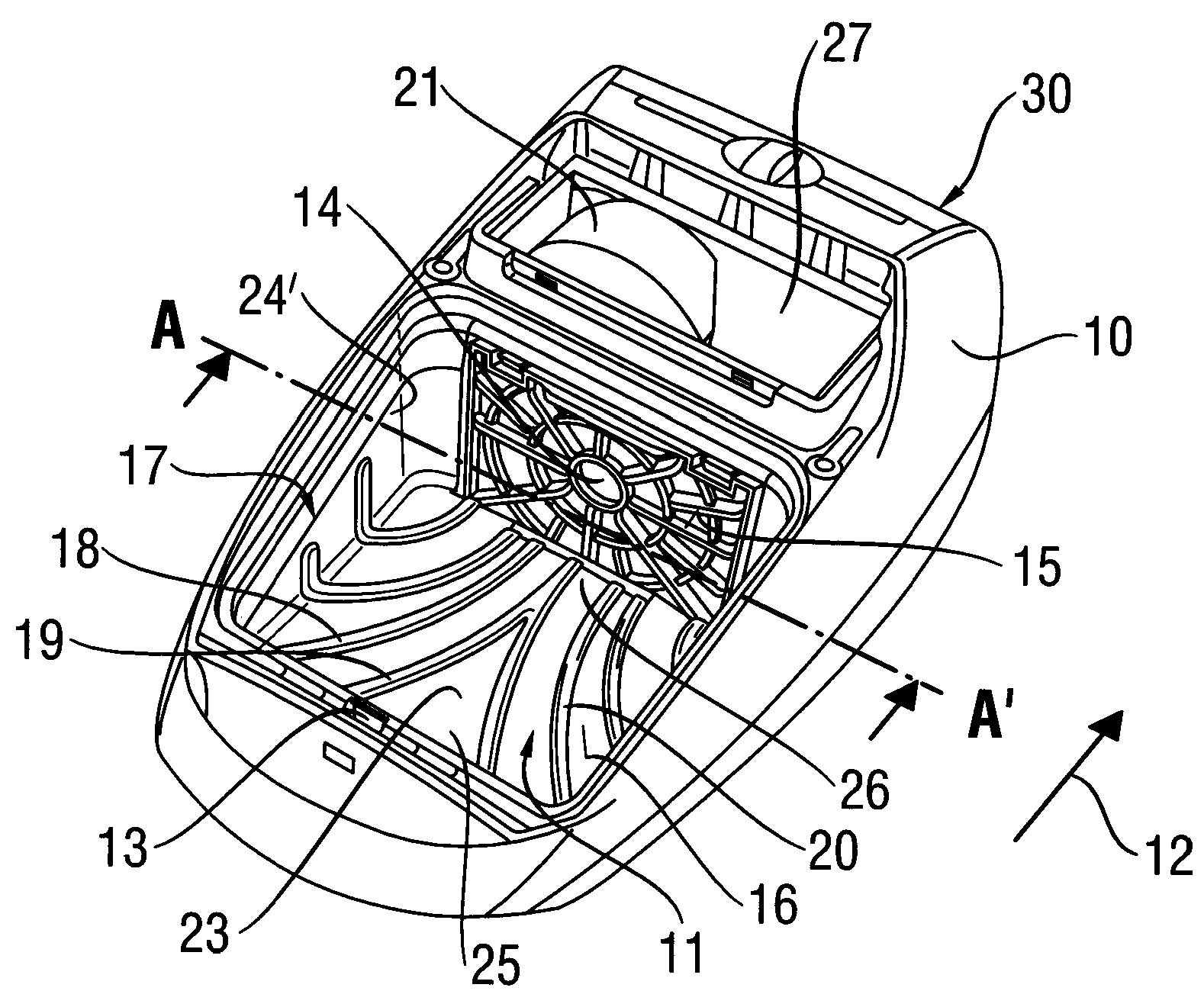

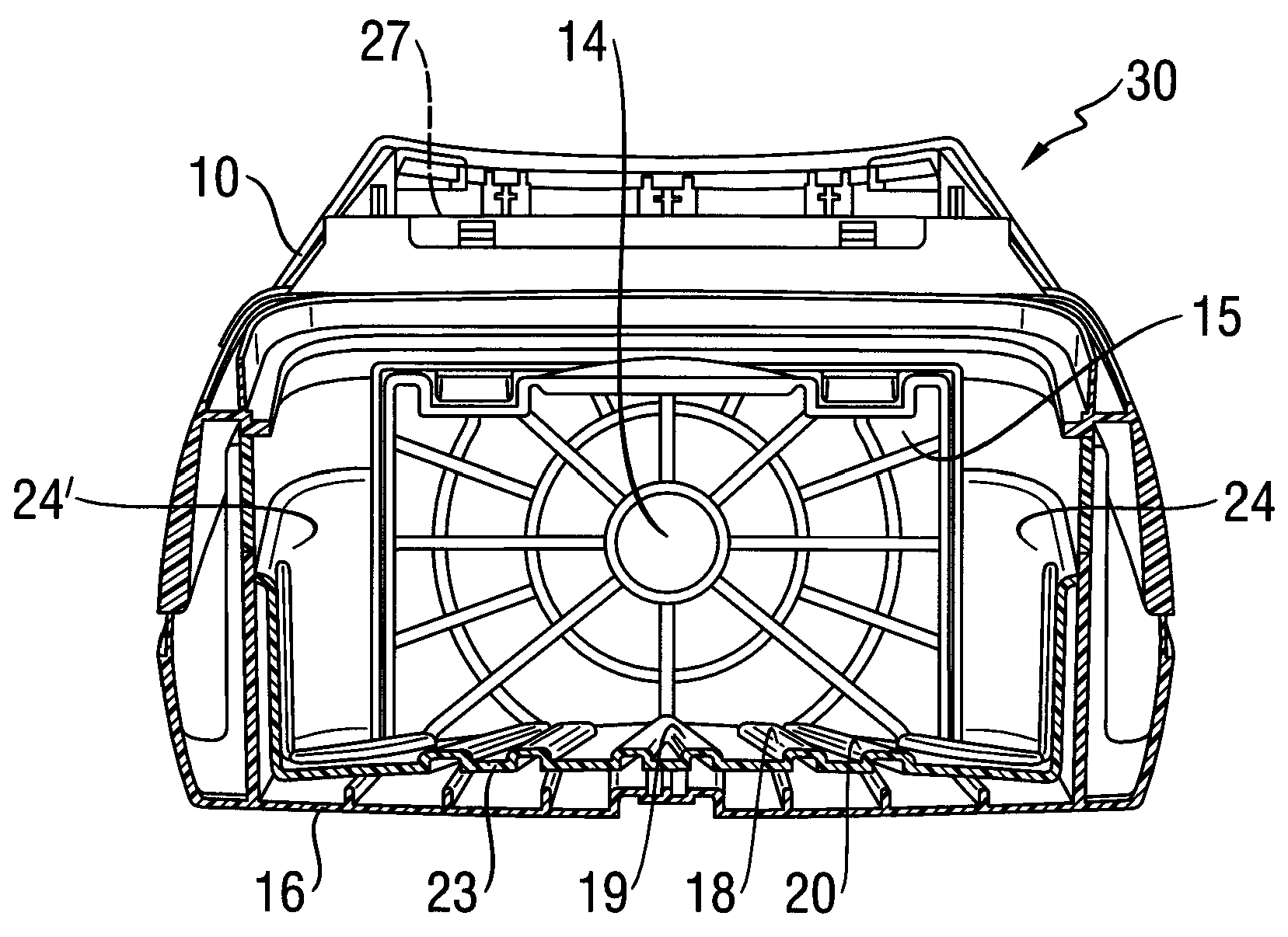

[0029] figure 1 A perspective view of a preferred exemplary embodiment of an insert 17 with ribs 18 , 19 , 20 for a dust chamber 11 of a vacuum cleaner 30 is shown. figure 2 shows the assembled state of the insert 17 and the vacuum cleaner 30, image 3 Shown along the section line A-A' figure 2 cutaway view.

[0030] The vacuum cleaner 30 has a housing 10 with a dust chamber 11 arranged in the housing 10 in which a not shown dust container is arranged. The dust chamber 11 can be opened via a dust chamber cover. exist figure 2 The vacuum cleaner 30 is shown without a dust chamber cover. The blower chamber 27 is adjacent to the dust chamber 11, and the blower 21 is provided in the blower chamber. Air is sucked in from the dust chamber 11 by the blower 21 through the air outlet 14 . The sucked-in air flows into the dust chamber 11 via an air inlet 13 via a connection (not shown). The dust chamber 11 is thus loaded with a negative pressure and the clean air flow 22 (see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com