Method for ultrasound shot-blasting of turbomachine parts

A technology of shot blasting and ultrasonic waves, which is applied in the direction of manufacturing tools, vibrating devices, abrasives, etc., can solve the problems that the laser shock extrusion method cannot be used, and the surface of the component is not enough to treat the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In a jet engine, the rotor disk has a rim around which are mounted removable blades. The blades are mounted in axial grooves, for example in the form of a dovetail joint, which are machined into the rim, and the blade including the root, which is also in the form of a dovetail joint, is machined at the bottom of the blade and the root is inserted into the recess Assembly is possible in the slot. Blade roots slide into grooves with limited backlash. The blade root is axially fixed by means of an axial fixing hook connected to the blade root. The hook cooperates with a transverse retaining ring located between the blade root and the hook. To this end, the grooves contain the axial movement of the blade root. The platform located on the top surface of the blade root limits the range of gas ejection. The material is selected from the class of steel, titanium alloys, nickel-based superalloys or aluminum.

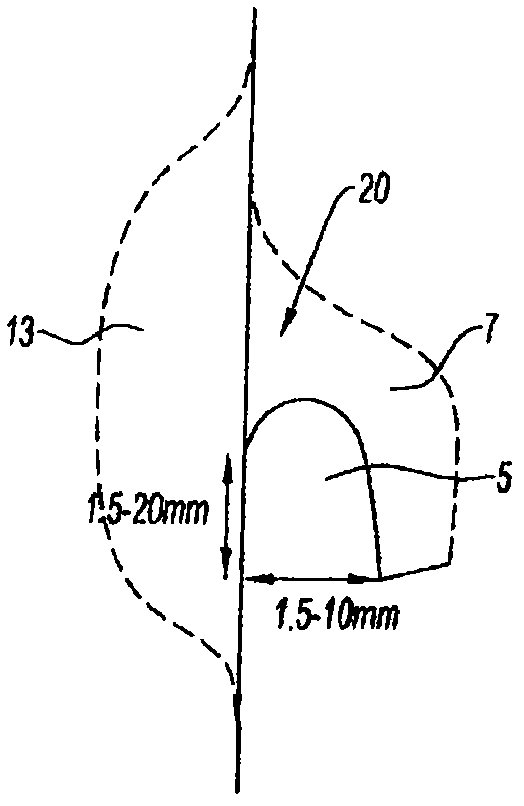

[0032] figure 1 For the geometry involved when applying the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com