Honeycomb paper element cutting device

A shearing device, honeycomb paper core technology, applied in cardboard articles, metal processing and other directions, can solve the problems of product quality can not be well guaranteed, jitter, shearing error and other problems, achieve simple structure, small shearing vibration , the effect of high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

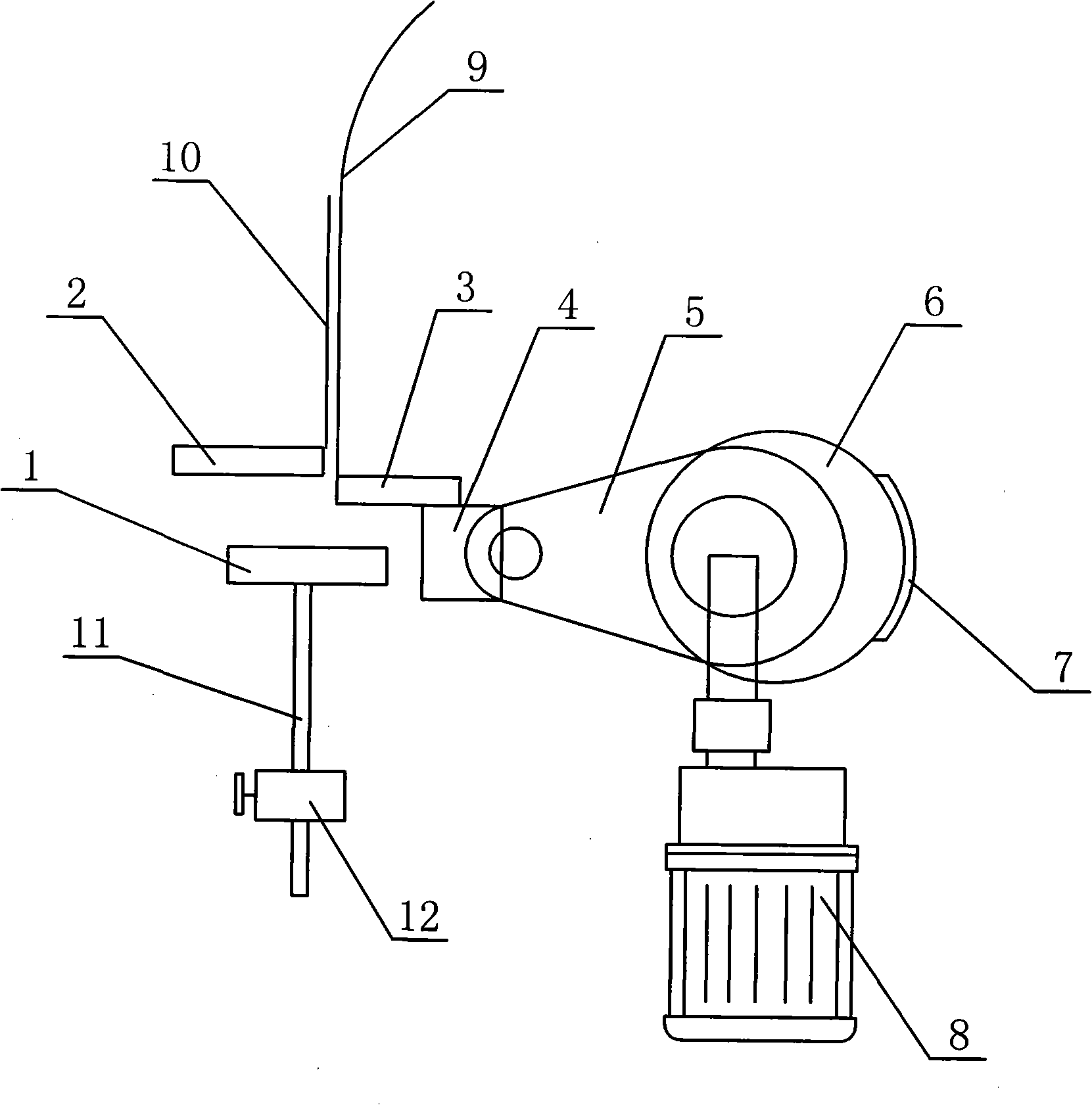

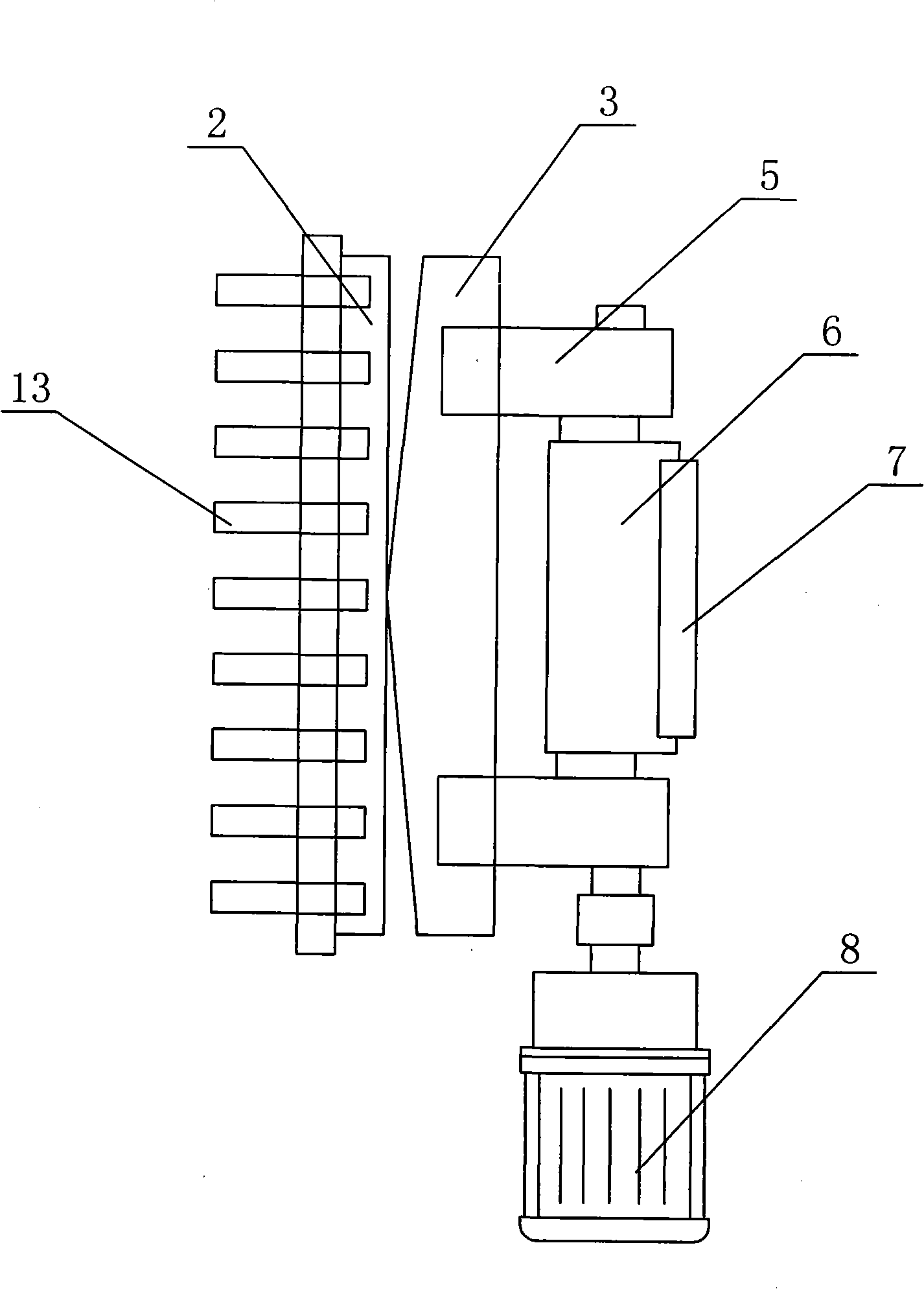

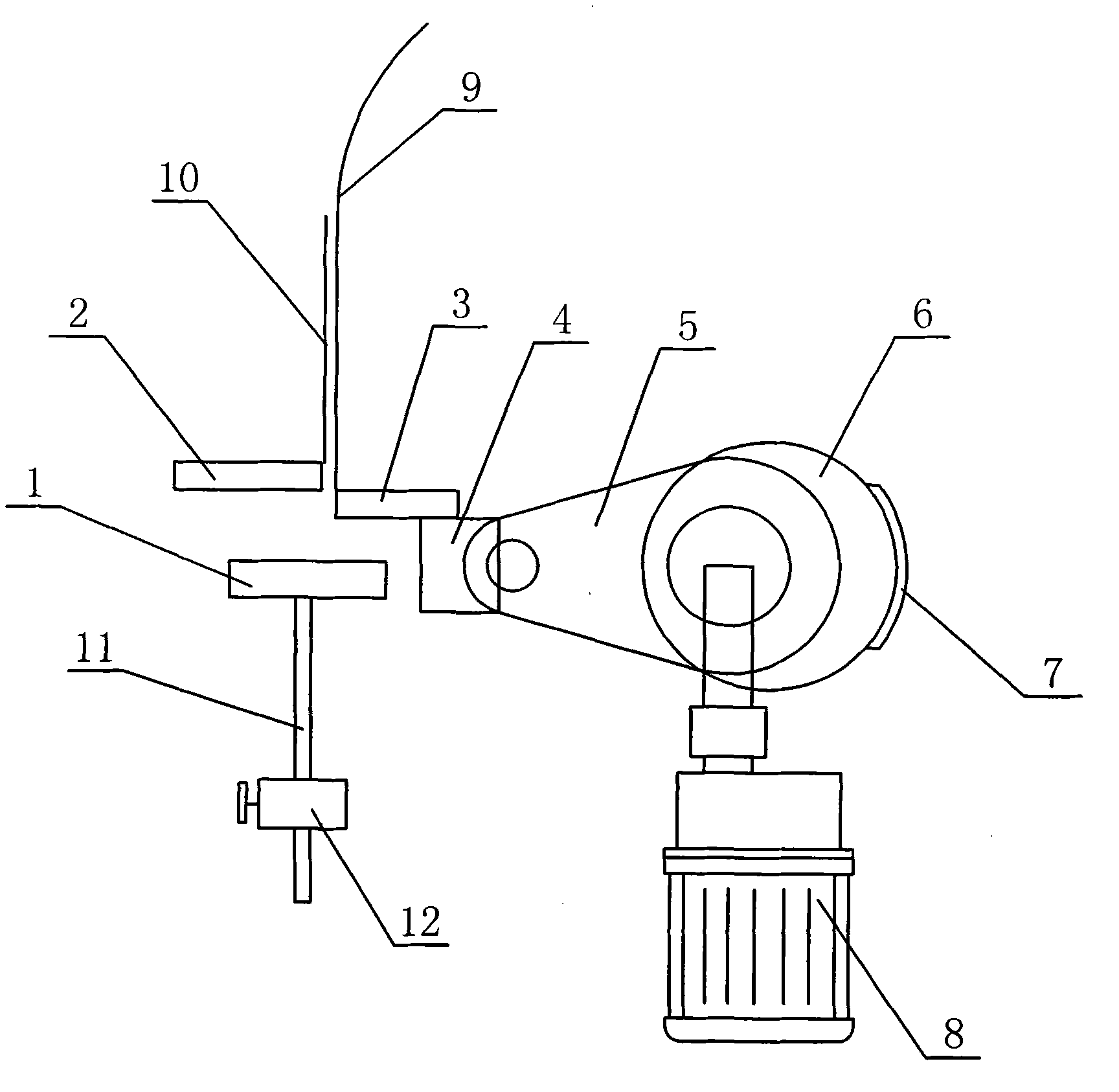

[0015] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of the honeycomb paper core shearing device of the present invention; figure 2 It is a structural schematic diagram of the cutting tool of the honeycomb paper core cutting device of the present invention.

[0016] In this embodiment, the honeycomb paper core shearing device includes a workbench 1, and a lift wire shaft 11 and a lift nut 12 are arranged below the workbench 1, and the height of the workbench 1 can be adjusted by adjusting the lift nut 12, and The top of the workbench 1 is provided with a movable knife 3 and a fixed knife 2 that are horizontally tangent up and down, the fixed knife 2 is fixed by a positioning block 13, and the movable knife 3 is fixed on the movable knife seat 4. The movable knife seat 4 is connected to the eccentric wheel 5, the eccentric wheel 5 is arranged on the eccentric shaft 6, the balance weight 7 is arranged on the eccentric shaft 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com