Deicing system for airfield runway

An airport runway and ice-melting technology, which is applied to roads, roads, pavement details, etc., can solve the problems of easy frost or ice on the surface of the runway, the impact of the normal operation of the airport, and the impact on the safety of the aircraft, and achieve low-cost ablation and defrosting Ice, reduce construction costs, avoid frost or icing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

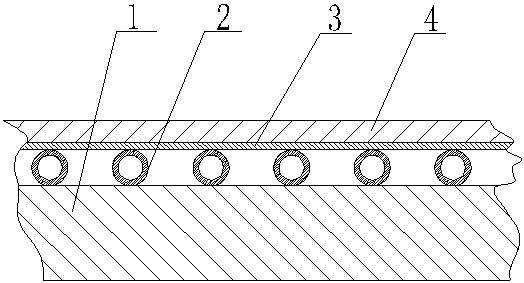

[0011] Such as figure 1 As shown, on the cement concrete base 1 lay a steel pipe 2 connected to the heating device in circulation, on the steel pipe 2 lay a load-bearing heat-conducting layer made of a steel plate 3, and finally lay cement concrete on the steel plate 3 surface layer4.

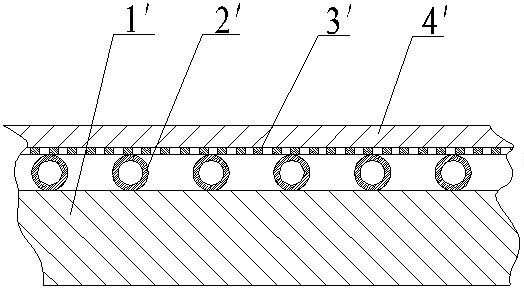

[0012] Such as figure 2 As shown, on the cement concrete base 1' lay a steel pipe 2' connected to the heating device, on the steel pipe 2' lay a load-bearing heat-conducting layer made of a mesh steel material layer 3', and finally in A cement concrete surface layer 4' is laid on the mesh rigid material layer 3'.

[0013] The invention can control the heating temperature and the flow rate of the heating device to achieve the best use effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com