Retractable type high-altitude oil filling device

A refueling device and telescopic technology, applied in the direction of engine components, engine lubrication, mechanical equipment, etc., can solve the problems of high labor intensity, long time for adding butter, etc., to eliminate potential safety hazards, shorten the time of adding butter, and realize semi-automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

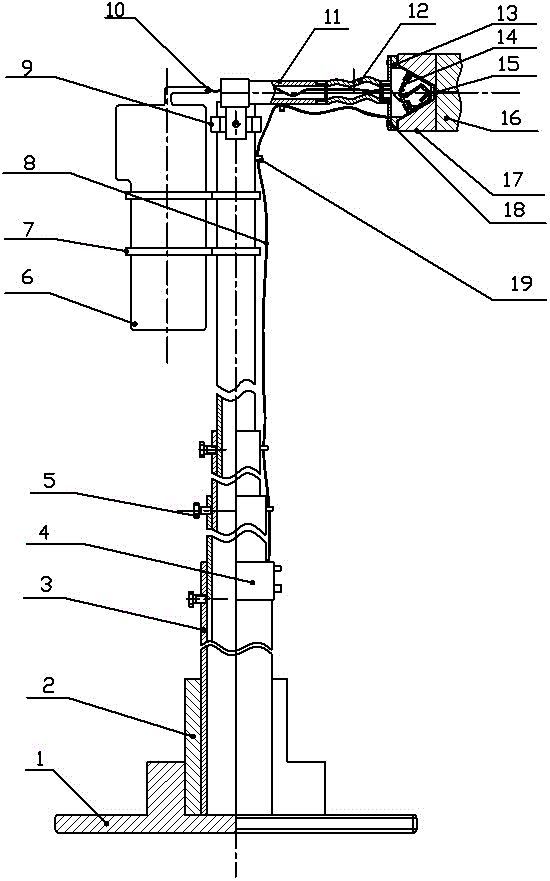

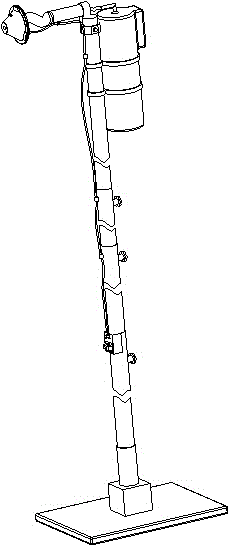

[0013] Embodiment one: see figure 1 , figure 2 with image 3 , the retractable high-altitude refueling device is composed of a base, a telescopic mechanism, a foldable support mechanism, a refueling mechanism, and a control part. It is characterized in that: the base is composed of a chassis 1 and a pipe joint 2, and the chassis 1 and The pipe joints 2 are connected by interference fit; the telescopic mechanism is composed of four telescopic rods 3, and the 3 telescopic rods are tightly connected by the plum blossom wheel screws 5, and the telescopic rods 3 have wire hole protrusions of the same size Block 19; the foldable support mechanism is composed of a sleeve 9, a rotating support rod 11, and a flexible joint 12. The rotating support rod 11 is close to the right end face of the sleeve 9, and the rotating support rod 11, the sleeve 9 is connected with the telescopic rod 3, and the flexible joint 12 is connected with the rotating support rod 11 through pipe threads; the...

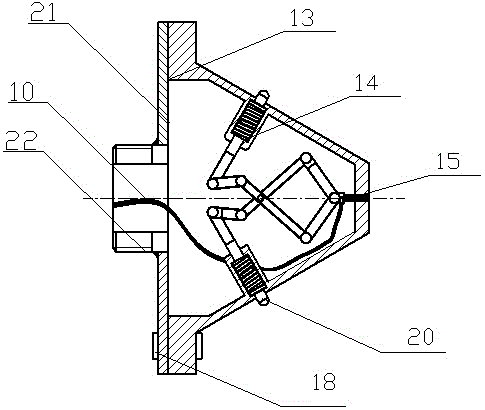

Embodiment 2

[0014] Embodiment two: see figure 1 , figure 2 with image 3 , this embodiment is basically the same as Embodiment 1, and the special features are as follows: the trigger mechanism 14 is composed of a connecting rod and a spring, and the funnel cover 13 is closely attached to the oil receiving chuck 17 to press the trigger button 20 to drive the trigger mechanism 14 Thereby the gun head 15 is stretched out. An electromagnet 18 is attached to the bucket-shaped oil filling head, and the electromagnet 18 can be controlled by the control box 4 to realize the absorption or release of the oil receiving chuck 17 by the bucket-shaped oil filling head. Described oil receiving chuck 17 is installed in the position that needs refueling, and is used when not taking off again for refueling.

[0015] The working principle of the retractable high-altitude refueling device is as follows:

[0016] 1. First, install the oil receiving chuck 17 at the position where oil needs to be refueled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com