Method and device for achieving in-situ activation of SCR catalyst by utilizing ozone

An SCR catalyst and catalyst technology, applied in the field of SCR flue gas denitrification, can solve problems such as narrow application range, complex flue gas components, and difficulty in ensuring long-term efficient operation of SCR catalysts, so as to improve utilization rate, realize in-situ activation and regeneration, shorten Effect of ozone addition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

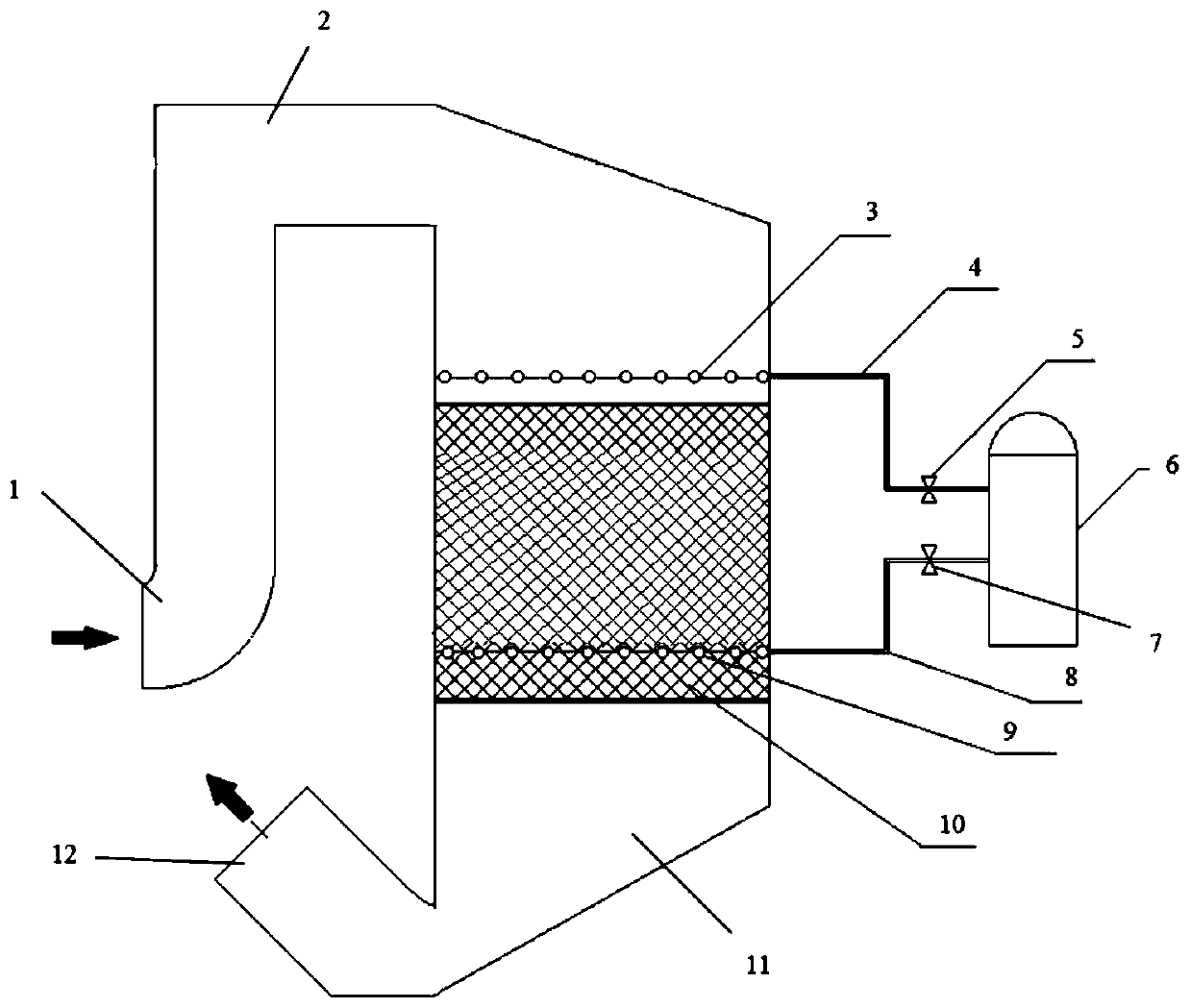

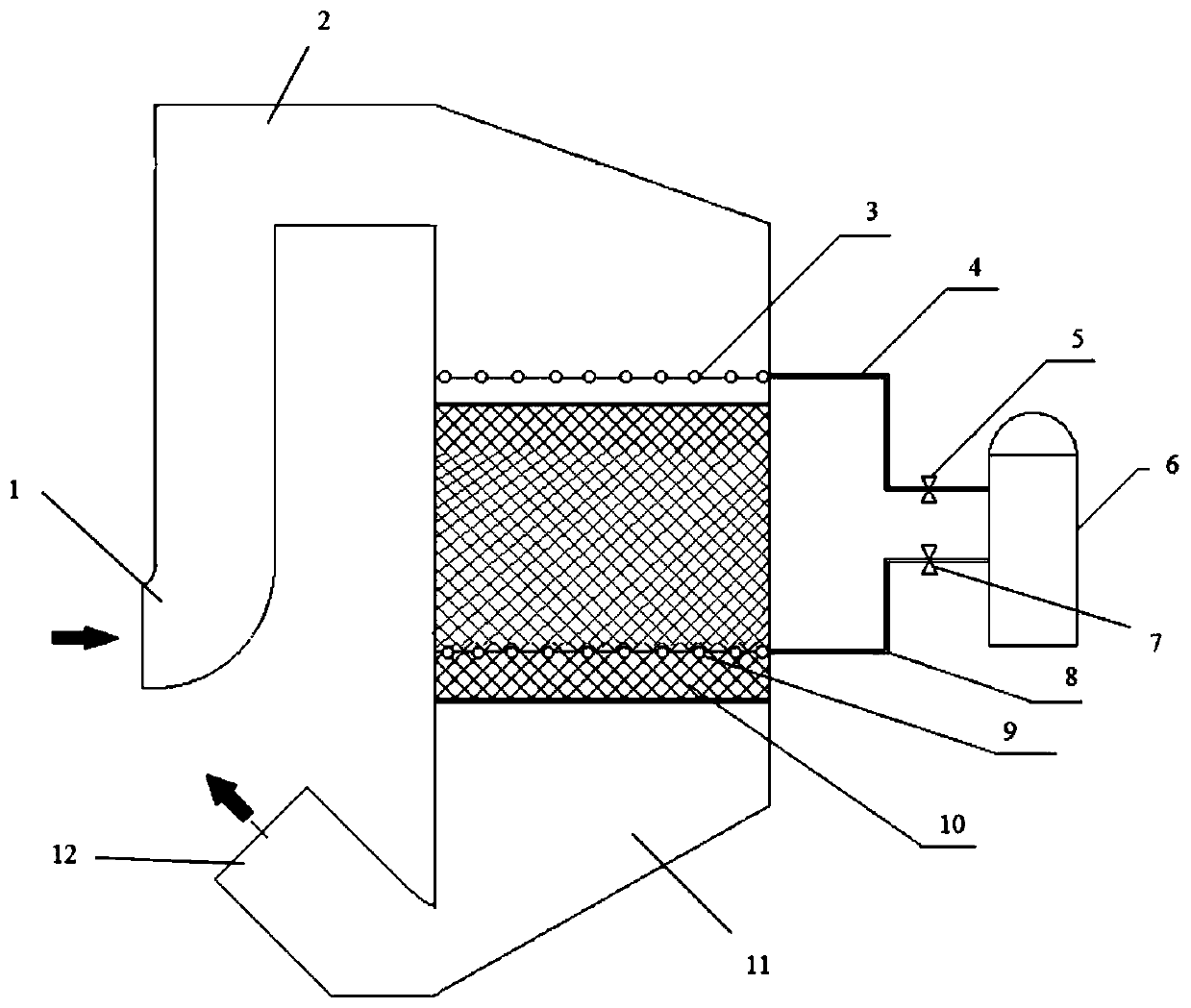

[0029] Such as figure 1As shown, this embodiment provides a catalytic device for in-situ activation of SCR catalysts using low-concentration ozone, including an SCR catalytic reaction device for flue gas purification and an ozone activation device for in-situ activation of SCR catalysts. The SCR The catalytic reaction device includes: a flue gas inlet 1, a flue gas inlet pipe 2, an SCR catalyst bed 10, a flue gas outlet channel 11, and a flue gas outlet 12; the ozone activation device includes: a first ozone injection port 3, a first Ozone pipeline 4, first control valve 5, ozone generator 6, second control valve 7, second ozone pipeline 8, second ozone injection port 9;

[0030] The first ozone injection port 3 is arranged inside the flue gas inlet pipe 2, and is located between the flue gas inlet pipe 2 and the SCR catalyst bed 10, and the second ozone injection port 8 is arranged inside the SCR catalyst bed 9;

[0031] The ozone generated by the ozone generator is introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com