Reinforced and toughened polycarboxylate water reducer, preparation method and preparation device

A polycarboxylic acid-based, reinforced and toughened technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of water reducer product quality deterioration, accelerated polymer deterioration, and water reducer Poor work performance and other problems, to achieve the effect of convenient construction, saving reaction time, low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

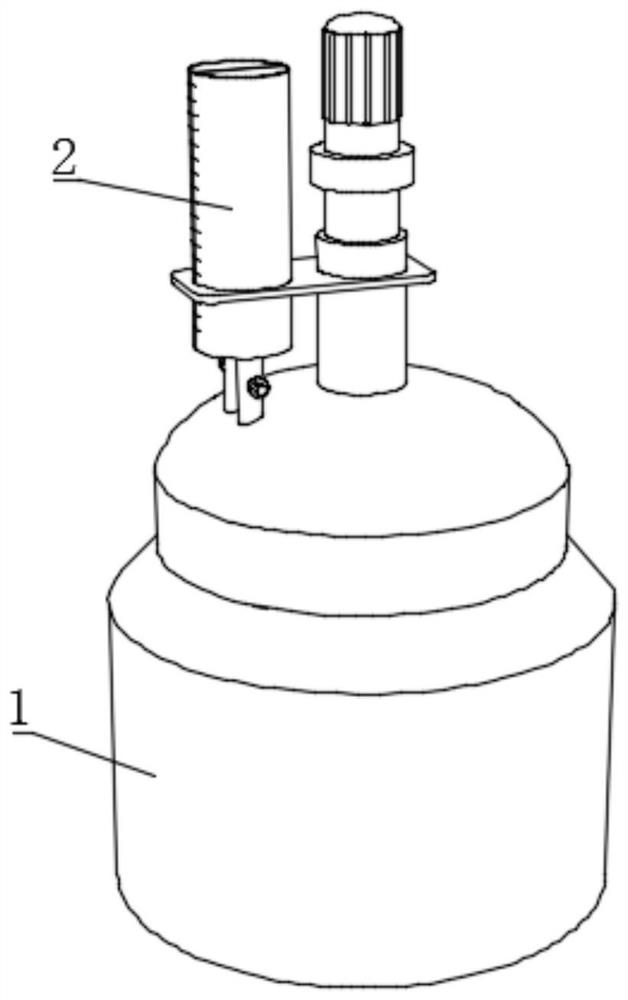

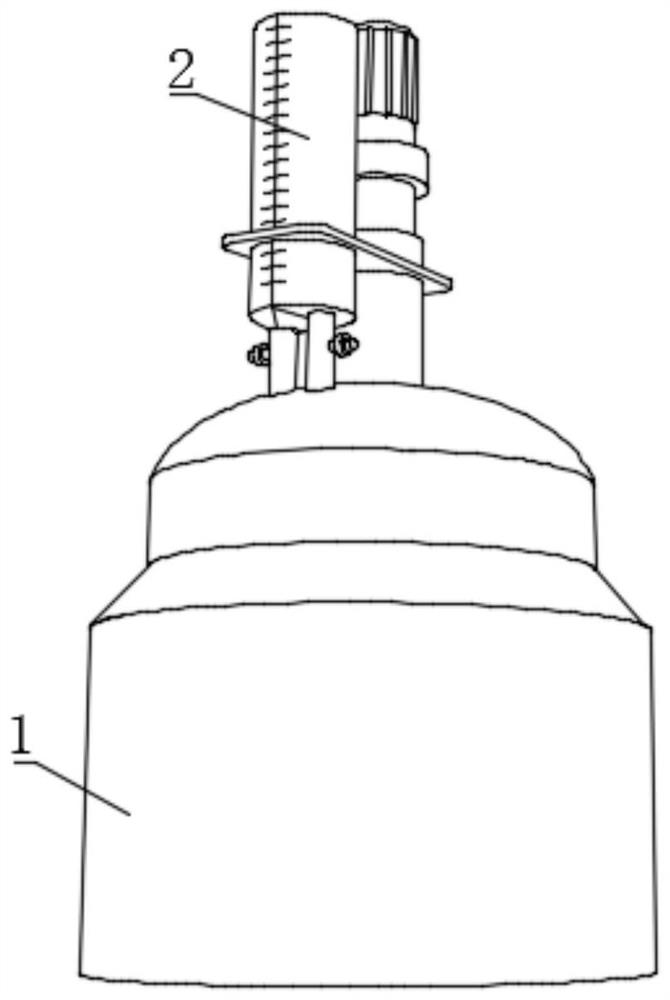

Image

Examples

Embodiment

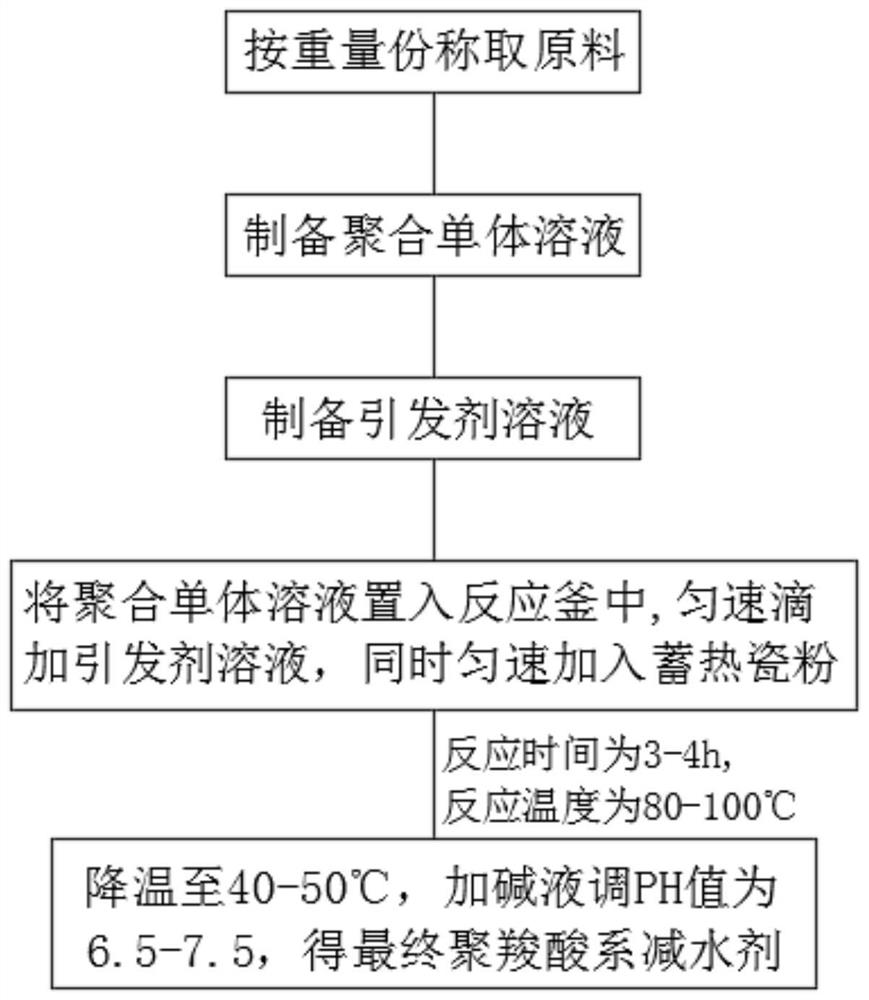

[0052] see figure 1 , a method for preparing a reinforced and toughened polycarboxylate water reducer, comprising the following steps:

[0053] The first step, take by weight 20 parts of methacrylic acid, 15 parts of acrylic acid, 10 parts of ethyl acrylate, 10 parts of hydroxyethyl acrylate, 10 parts of sodium allyl sulfonate, 8 parts of methyl methacrylate, 5 parts of allyl polyoxyethylene ether, 0.5 parts of initiator, 3 parts of thermal storage porcelain powder, and 1 part of molecular weight regulator;

[0054] The second step: mix methacrylic acid, acrylic acid, ethyl acrylate, hydroxyethyl acrylate, sodium allyl sulfonate, methyl methacrylate, allyl polyoxyethylene ether, molecular weight regulator and deionized water, Making a polymerized monomer solution with a content of 50% by mass percentage;

[0055] The third step: the initiator is mixed with water to make an initiator solution with a content of 10% by mass percentage;

[0056] The initiator is selected from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com