Groove broacher for commutator of direct current motor

A DC motor and commutator technology, applied in the direction of current collector maintenance, etc., can solve the problems of large quality fluctuation, long maintenance time, low operation efficiency, etc., and achieve the effects of low manufacturing cost, reduced labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

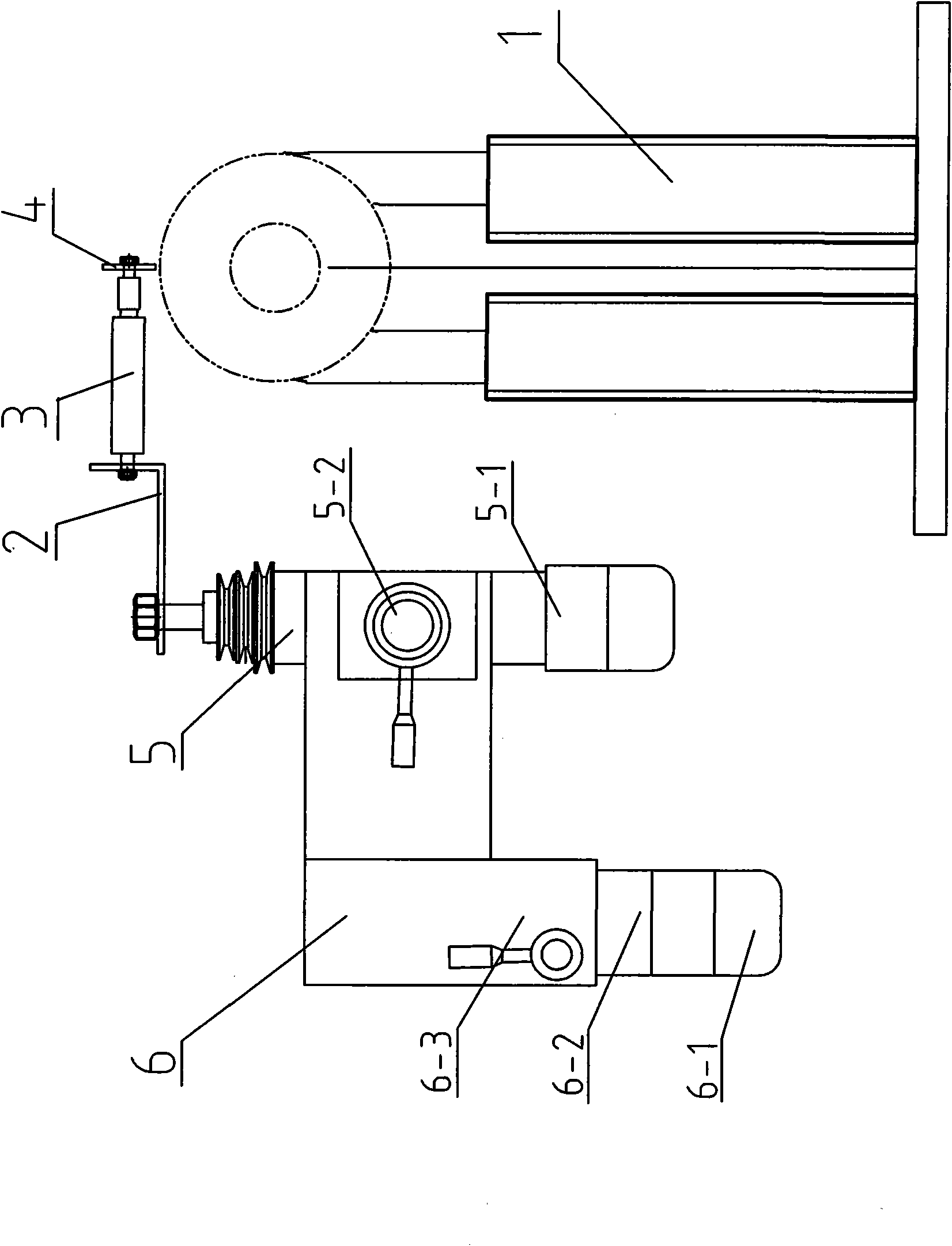

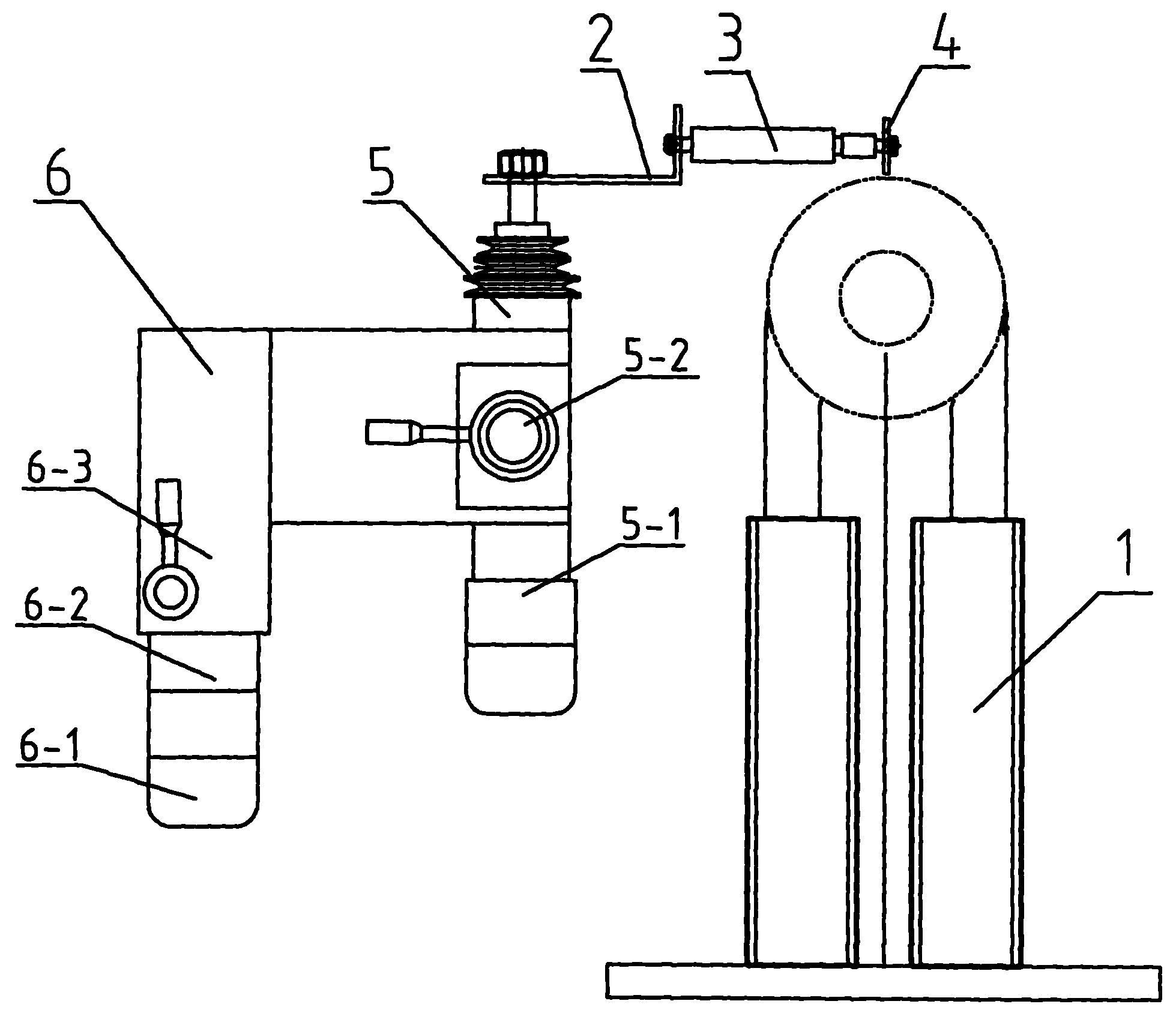

[0012] as attached figure 1 As shown, a DC motor commutator slotting machine includes a rotor bracket 1, a pneumatic motor 3 arranged on the cutting frame 2, a cutting tool 4 connected with the pneumatic motor 3, and a mechanism for controlling the cutting frame 2 to move up and down. Adjust the controller 5 up and down, and control the front and rear adjustment controller 6 that the cutting frame 2 moves forward and backward.

[0013] The up and down adjustment controller 5 includes a positioning lever handle 5-1 and a positioning gear set 5-2.

[0014] The front and rear adjustment controller 6 includes a motor 6-1, a transmission mechanism 6-2 and a walking guide rail 6-2.

[0015] After the DC motor commutator that needs to be overhauled is processed by a lathe, it is placed on the rotor support 1 and the mica sheet groove that needs to be cut is placed on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com