Multishaft synchronous servo driving system and synchronous control method thereof

A servo-driven, multi-axis synchronization technology, which is applied in the direction of multiple motor speed adjustments, can solve the problems of low execution effect, low cost performance, and separation from centralized control methods, and achieve the effects of enhanced synchronization, high cost performance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

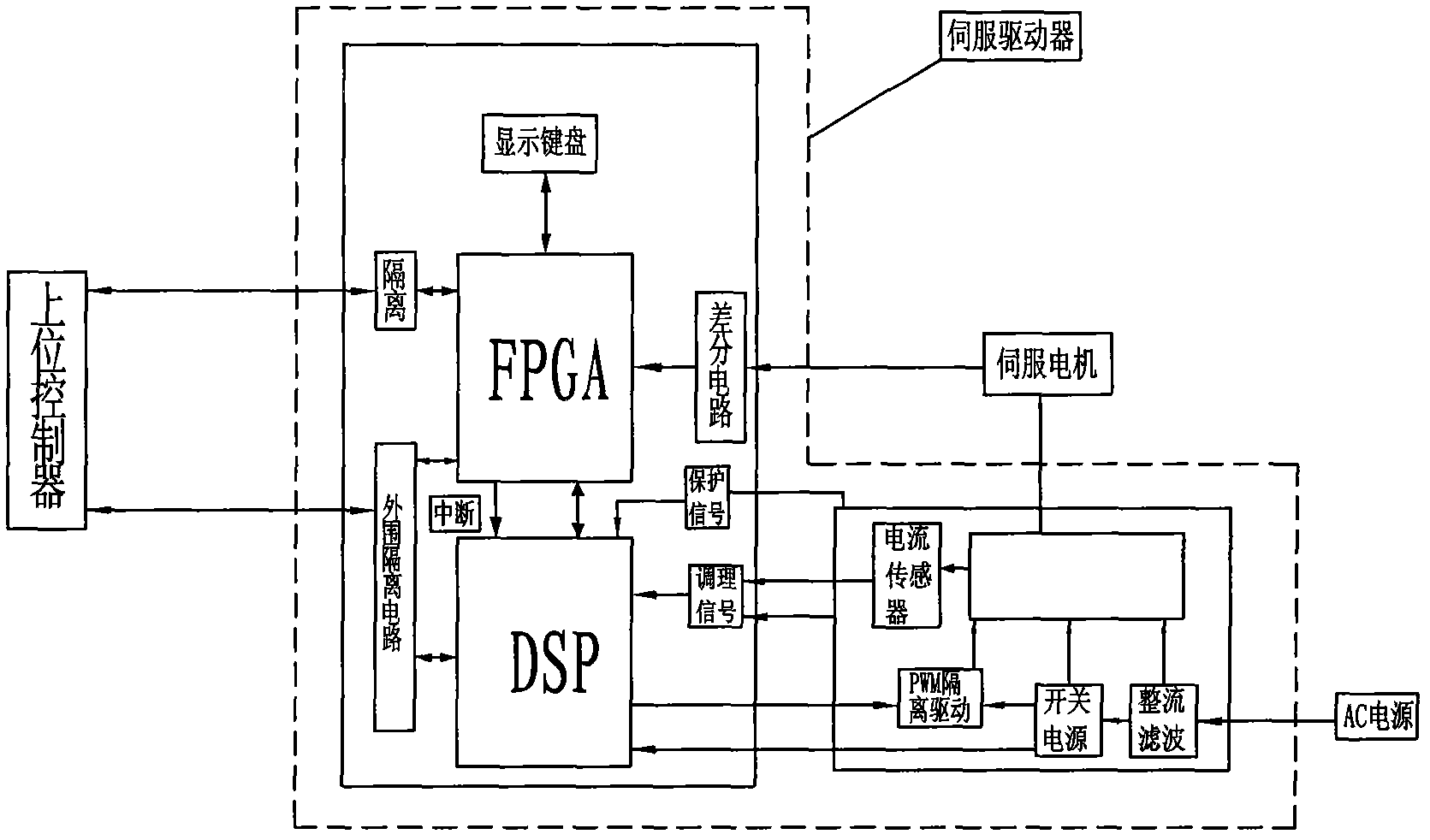

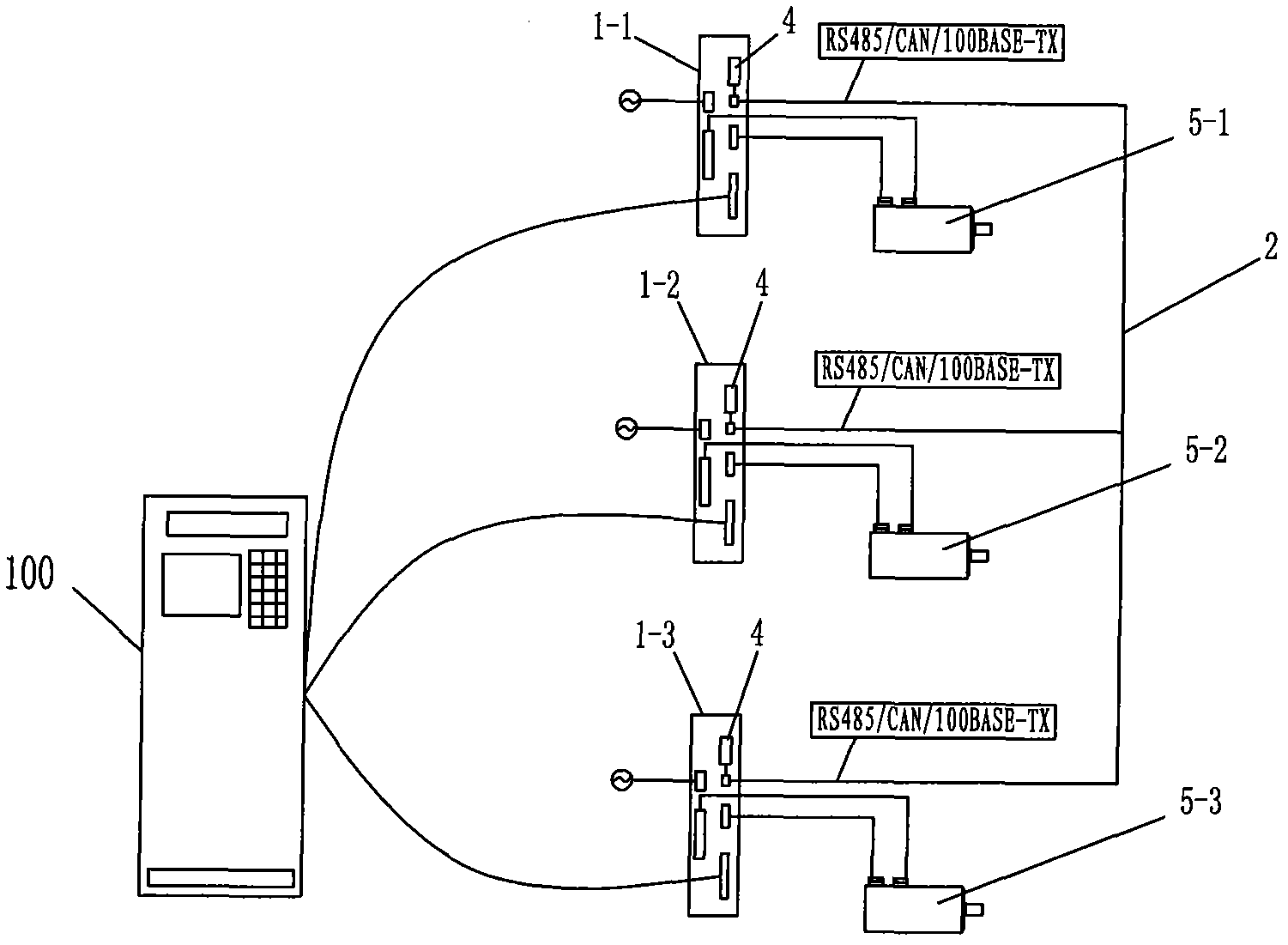

[0033] The multi-axis servo drive system of this embodiment is as image 3 As shown, it includes a host controller 100, three servo drivers 1-1, 1-2, 1-3 and three servo motors 5-1, 5-2, 5-3. This embodiment selects three a servo drive. The servo drive generally contains FPGA unit, DSP unit, current loop control loop unit, speed loop control loop unit, position loop control loop unit and auxiliary circuit; the input end of the servo drive is connected to the host controller, and its output end is connected to the servo drive. motor. All of the above are prior art, and other prior art will not be repeated here.

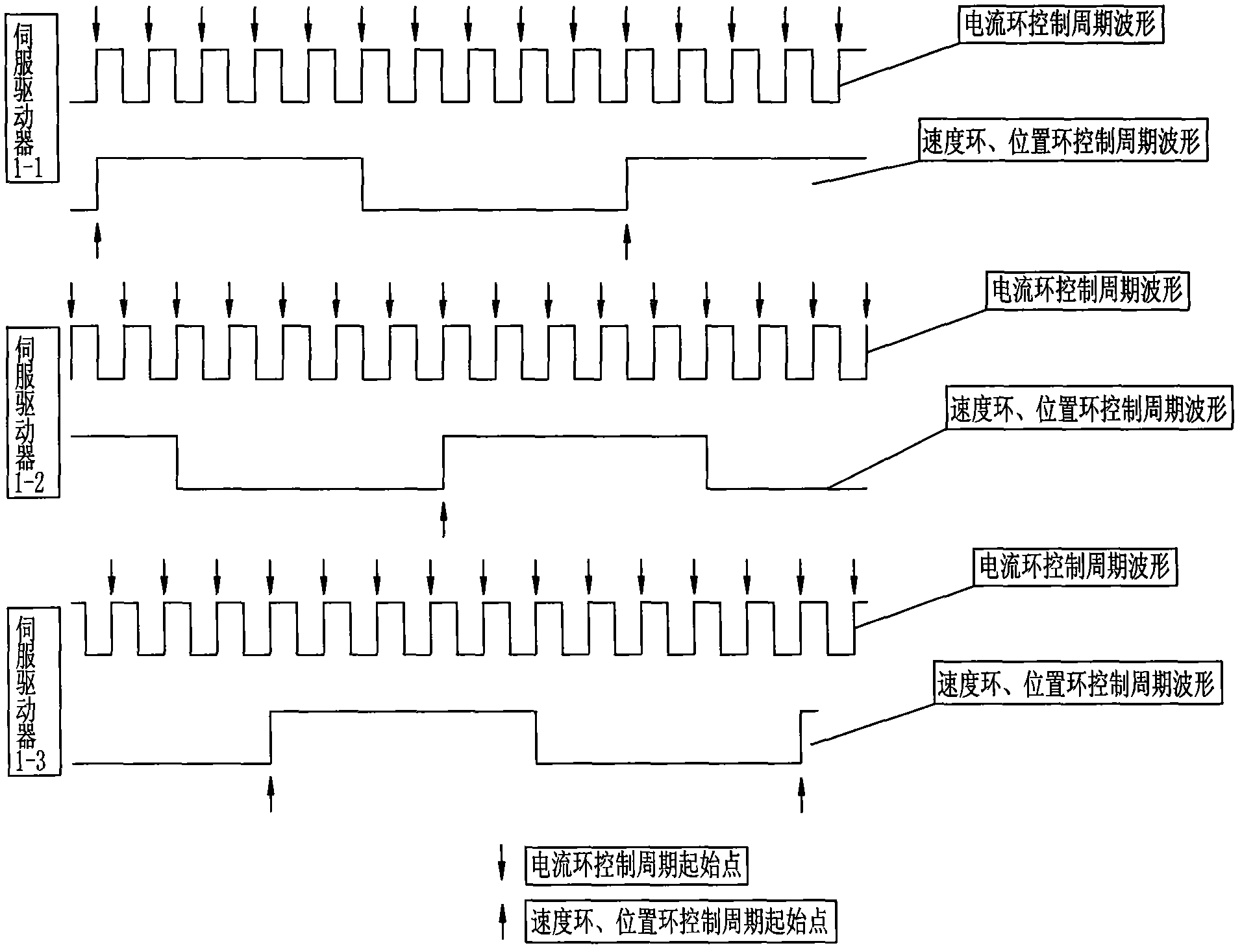

[0034] Three servo drives 1-1, 1-2, 1-3 all contain Synchronous interrupt processing module 4 and the three servo drives 1-1, 1-2, 1-3 are connected to each other with a synchronous communication bus 2, and one of the servo drives 1-1 is to connect it Synchronous interrupt processing module 4 is set to regularly send synchronous signals to the synchronous communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com