Ultra wide band electromagnetic band gap structure for suppressing ground bounce noise of high speed circuit/microwave circuit

An electromagnetic bandgap, broadband technology, applied in circuits, printed circuit components, electrical components, etc., can solve problems such as damage to power integrity, achieve good power integrity, achieve power integrity, and suppress ground bounce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

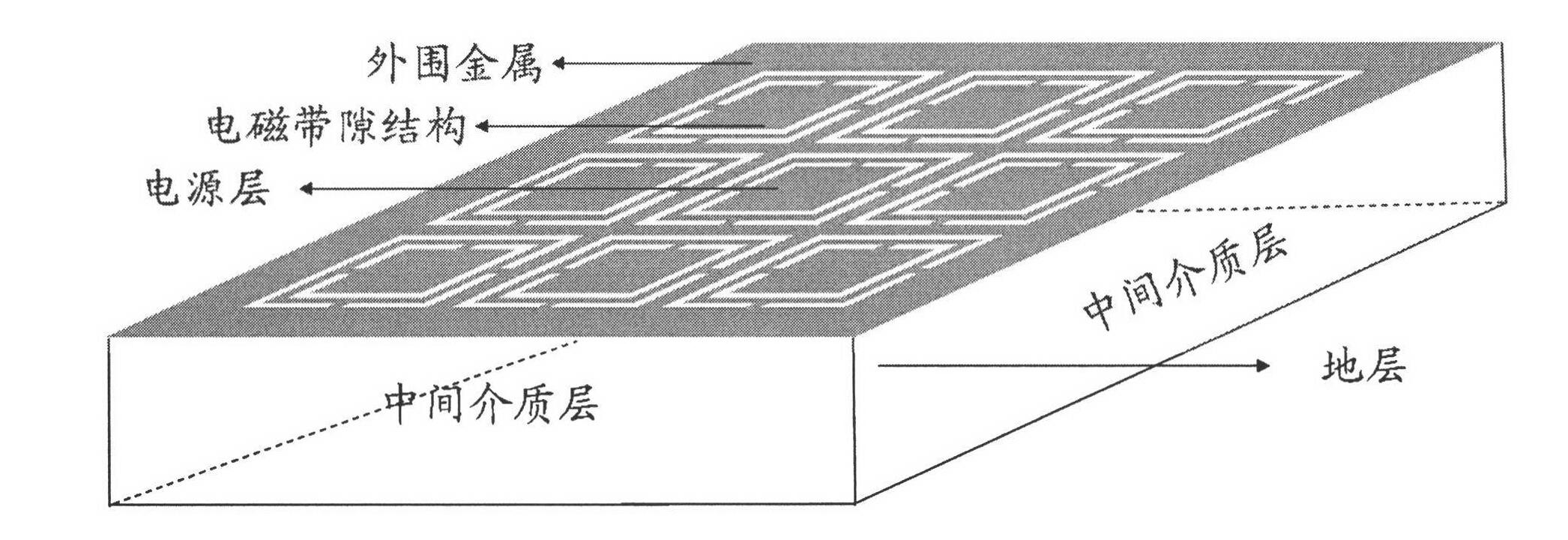

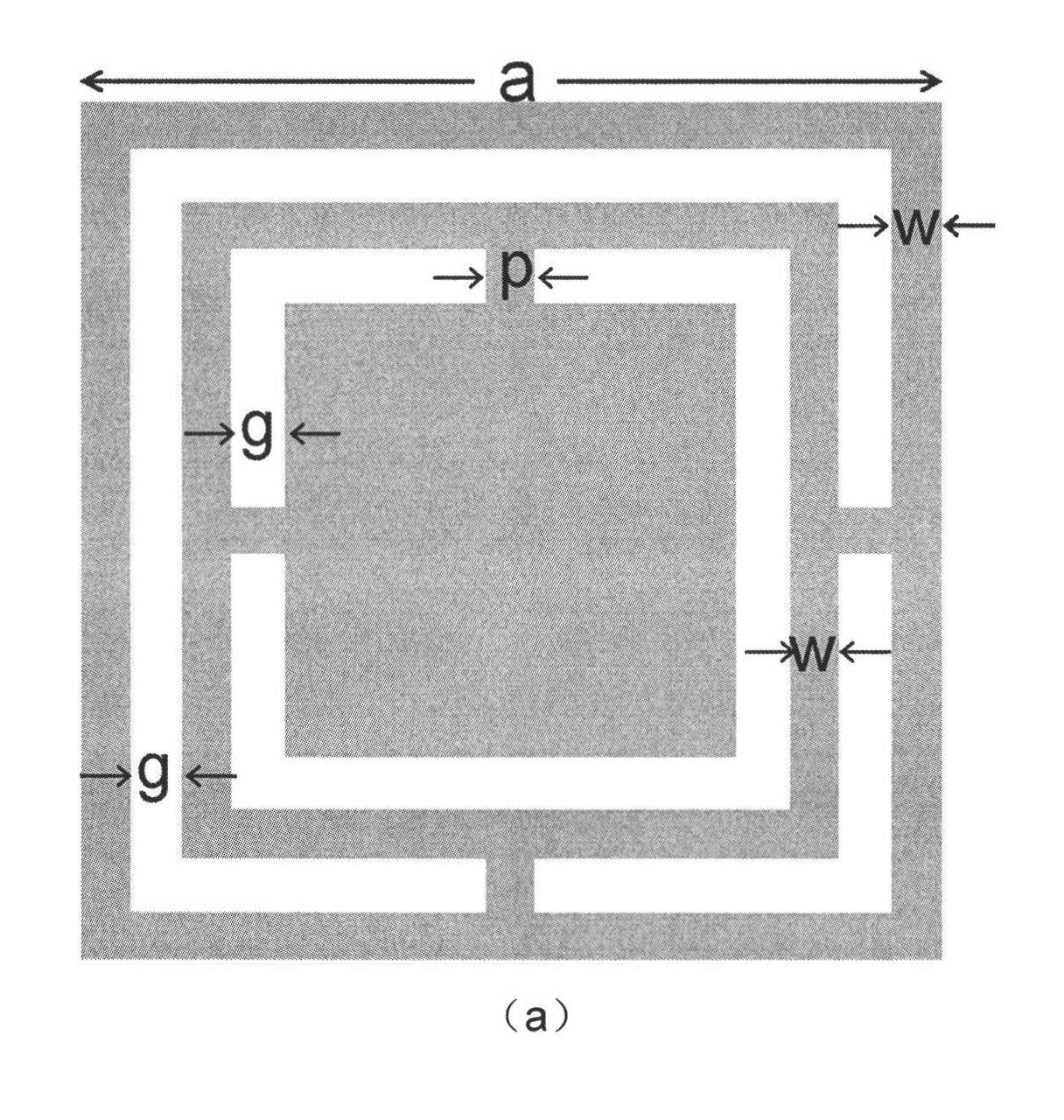

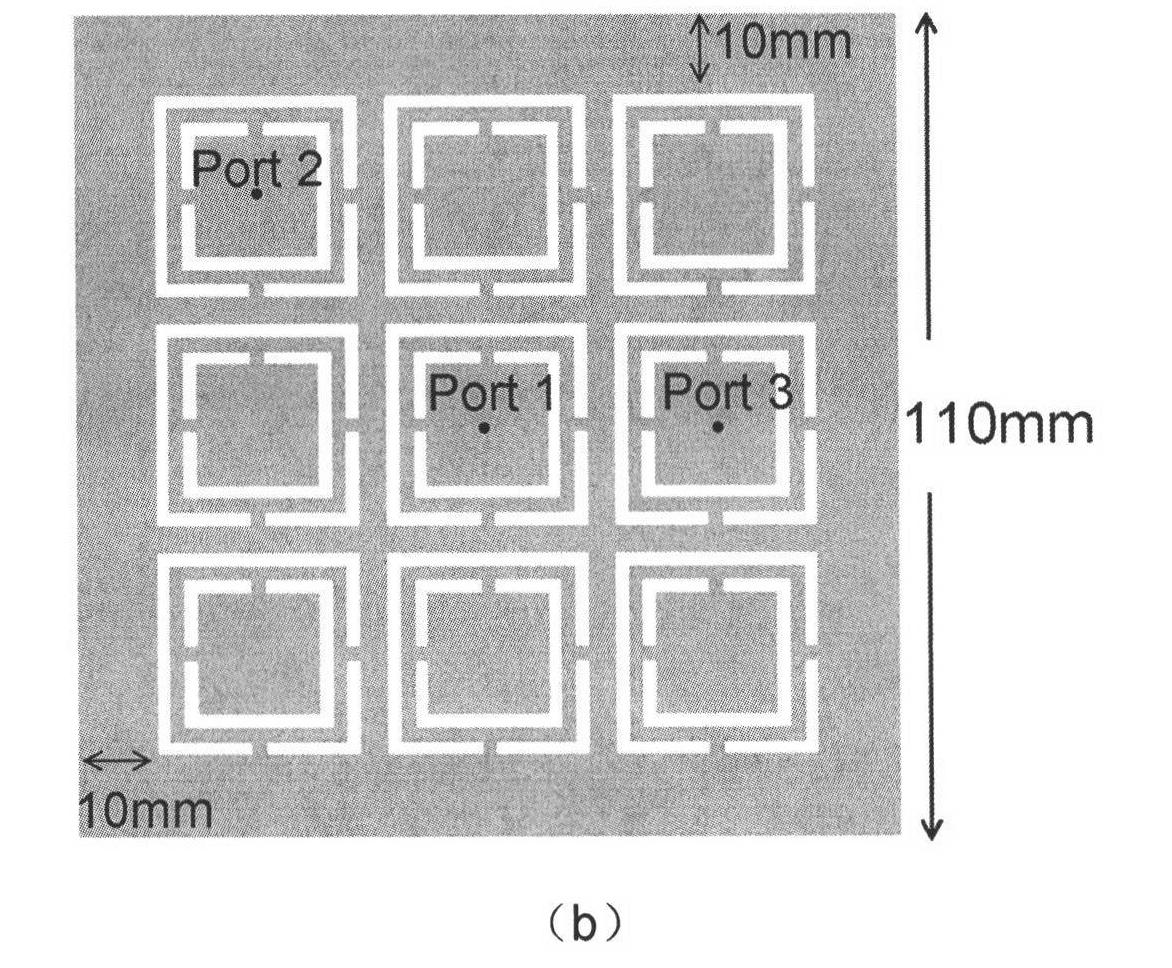

[0010] Firstly, a sample with a three-layer structure as proposed in the technical scheme needs to be prepared. The middle is a dielectric plate, the material can be selected such as polytetrafluoroethylene, FR4, Roger series and other dielectrics, the upper and lower layers are copper-clad, one side is continuous, and the other side needs to be etched into such as figure 2 electromagnetic bandgap structure.

[0011] After the processing is completed, it needs to be verified by specific experiments. When it is confirmed that it can achieve an insertion loss lower than -30dB for any two ports in a certain frequency band, it can be used as an ordinary high-speed circuit / microwave circuit. Replacement of power planes for suppression of ground bounce noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com