Ferritic stainless steel sheet for egr coolers

A technology of EGR cooler and stainless steel plate, which is applied in the direction of adding non-fuel substances to the charging system, machine/engine, fuel, etc., can solve the problems of formability and other problems, and achieve the effect of excellent brazeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

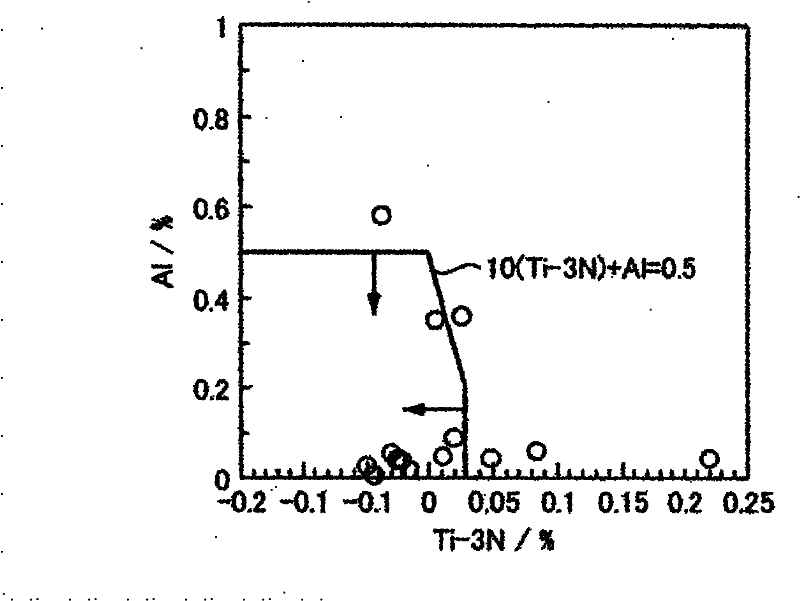

[0062] For the EGR cooler, brazability due to Ni or Cu is required. Therefore, the inventors of the present invention have earnestly studied the influence of alloy elements on brazeability. As a result, it was found that, as shown in the following formulas (1) and (2), in ferritic stainless steel sheets, Ti, which is often added for the purpose of improving workability or intergranular corrosion resistance, and Ti for the purpose of deoxidation On the other hand, Al to be added has an upper limit that can ensure good brazeability.

[0063] Ti-3N≤0.03 (1)

[0064] 10(Ti-3N)+Al≤0.5 (2)

[0065] To obtain good brazing properties, the molten solder needs to be wetted and spread on the surface of the stainless steel plate, but the surface film formed on the stainless steel plate under the brazing atmosphere affects the wettability. In addition, in the brazing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com