Rolling bearing arrangement and wind turbine equipped therewith

A technology of wind power generation equipment and rolling bearings, applied in wind power generation, bearings, ball bearings, etc., can solve problems such as wear, large expenditure, and single rolling element stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

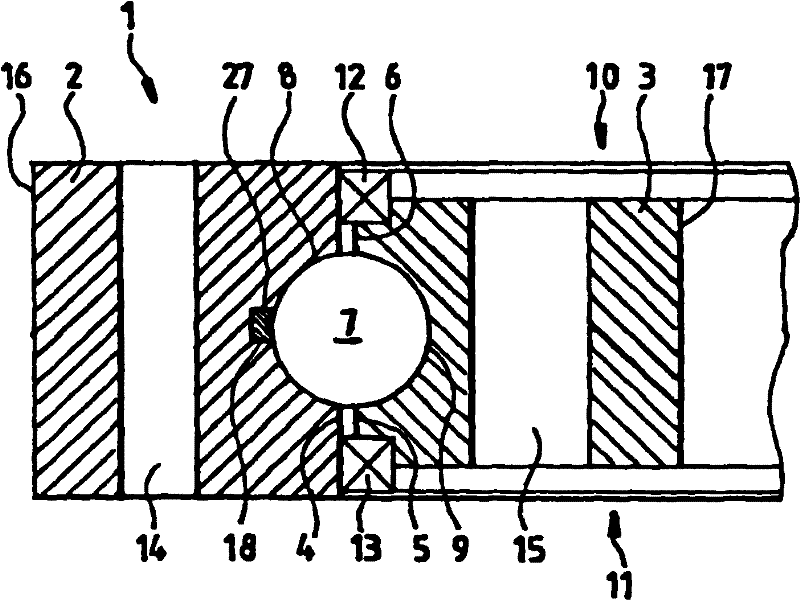

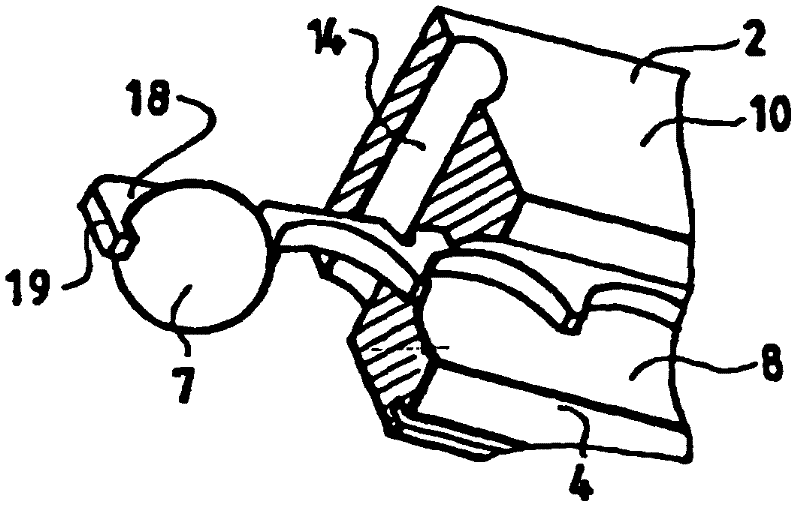

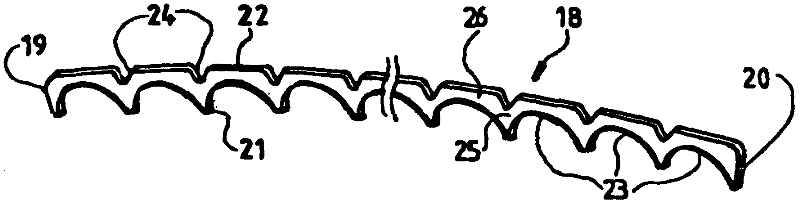

[0047] The rolling bearing 1 shown as an example in the drawing is used for the rotatable connection of a first plant or machine part to a foundation or a second plant or machine part. For this purpose, the rolling bearing 1 has two annular connecting elements 2 , 3 .

[0048] through according to figure 1 The cross-section of the rolling bearing 1 makes the internal structure of the rolling bearing 1 recognizable. A typical construction of a radial bearing can be identified, wherein the first connecting element 2 is designed as a planar outer ring (connecting element 2 in figure 1 can be seen on the left side of the center), while the second connecting element 3 is configured as an inner ring 3 concentrically arranged in the outer ring 2 ( figure 1 center on the right). The two connecting elements 2 , 3 each have an approximately rectangular cross section. Between the inner casing 4 of the outer connecting element 2 and the outer casing 5 of the inner connecting element 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com