Short-flow water purification process and device using immersed ultra-filtration membrane as core

An ultrafiltration membrane and immersion technology, which is applied in the field of short-flow water purification processes and devices with immersion ultrafiltration membranes as the core, can solve the problems of water source pollution, reduce the content of organic matter in effluent, etc., so as to solve water source pollution and ensure water supply. Safe, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

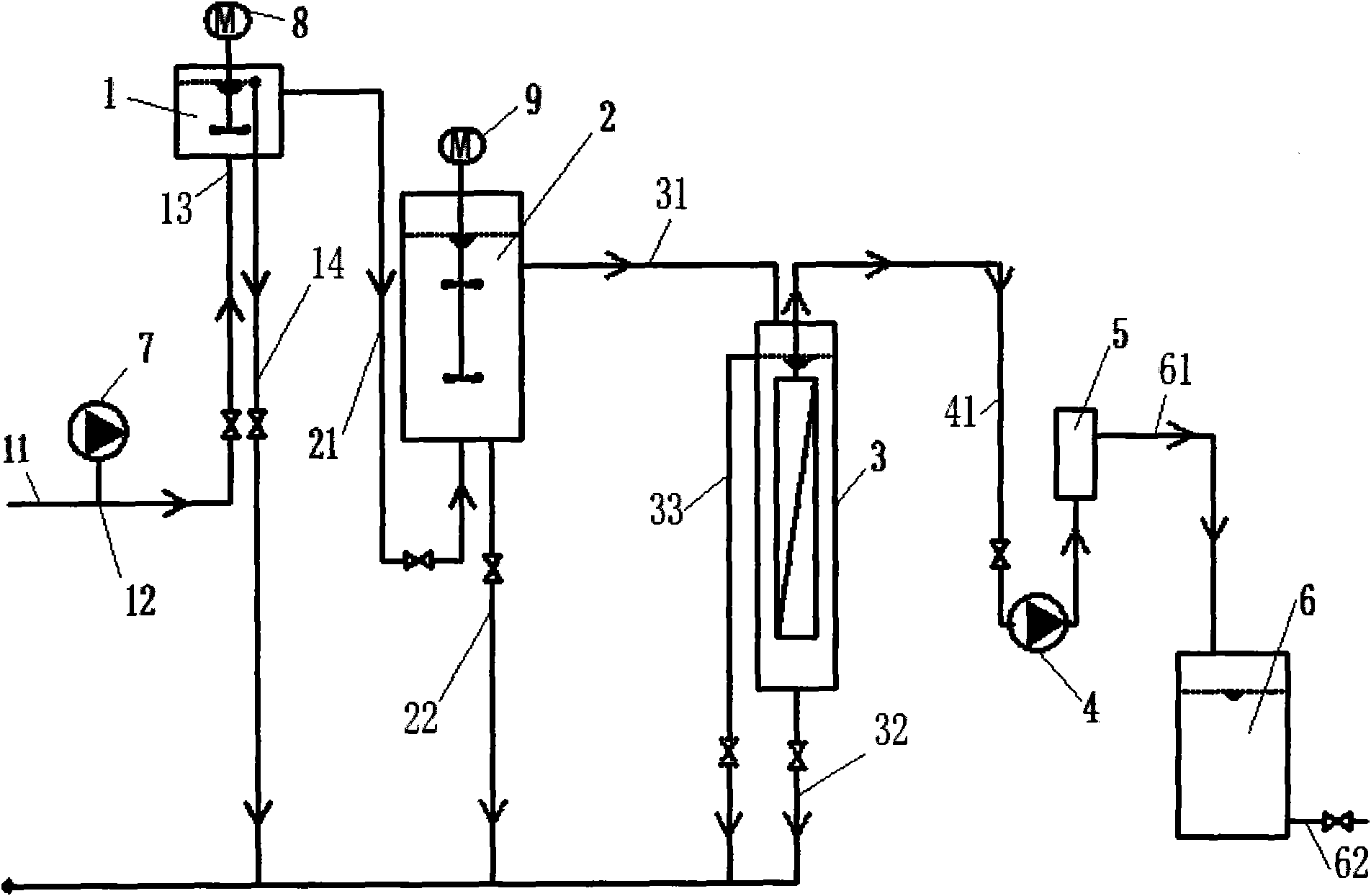

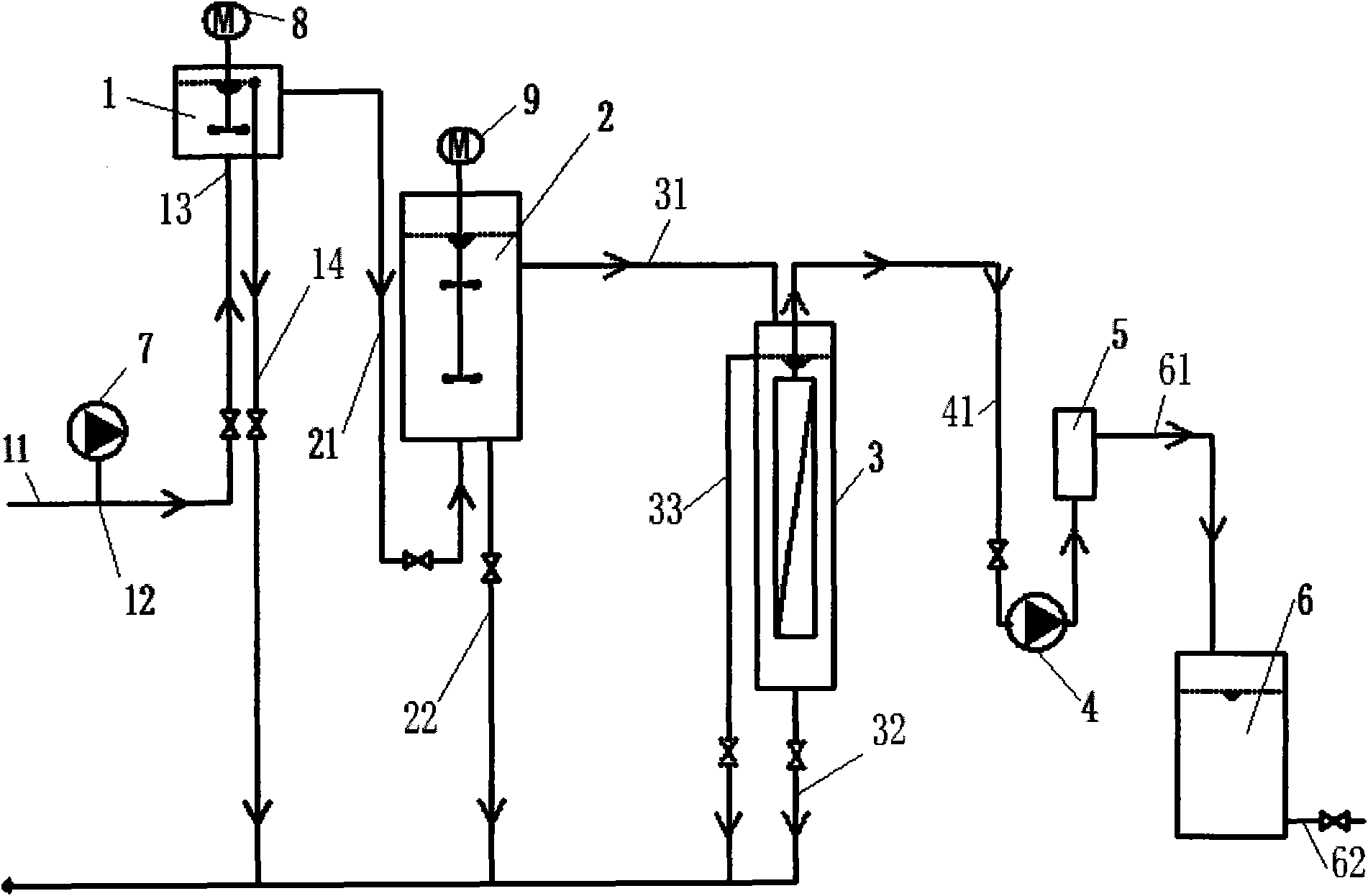

[0022] In the present invention, the short-process ultraviolet disinfection and oxidation raw water 11 with the submerged ultrafiltration membrane as the core enters from the bottom 13 of the mixing tank under pressurized conditions, and on the water inlet pipeline, a coagulant is added into the pipeline 12 through the dosing pump 7 . Stir with mixing agitator in the mixing tank 1 pool, the agitator rotating speed is 200 rev / min, and the average water retention time is 60 seconds, and the bottom of mixing tank 1 is provided with blowdown pipeline 14 simultaneously, regularly blowdown.

[0023] The outlet water from the mixing tank 1 is gravity flow, and flows into the flocculation tank 2 through the water inlet pipe 21 . The flocculation tank 2 is stirred with an agitator, the agitator rotating speed is 40 rpm, and the average water retention time is 10 minutes. The bottom of the flocculation tank 2 is provided with a sewage pipe 22 for regular sewage discharge.

[0024] The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap