Respirator for gear case

A technology of respirator and transmission box, which is applied in the field of respirator, can solve problems such as cost increase, and achieve the effects of convenient cleaning and replacement, high economic benefits, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

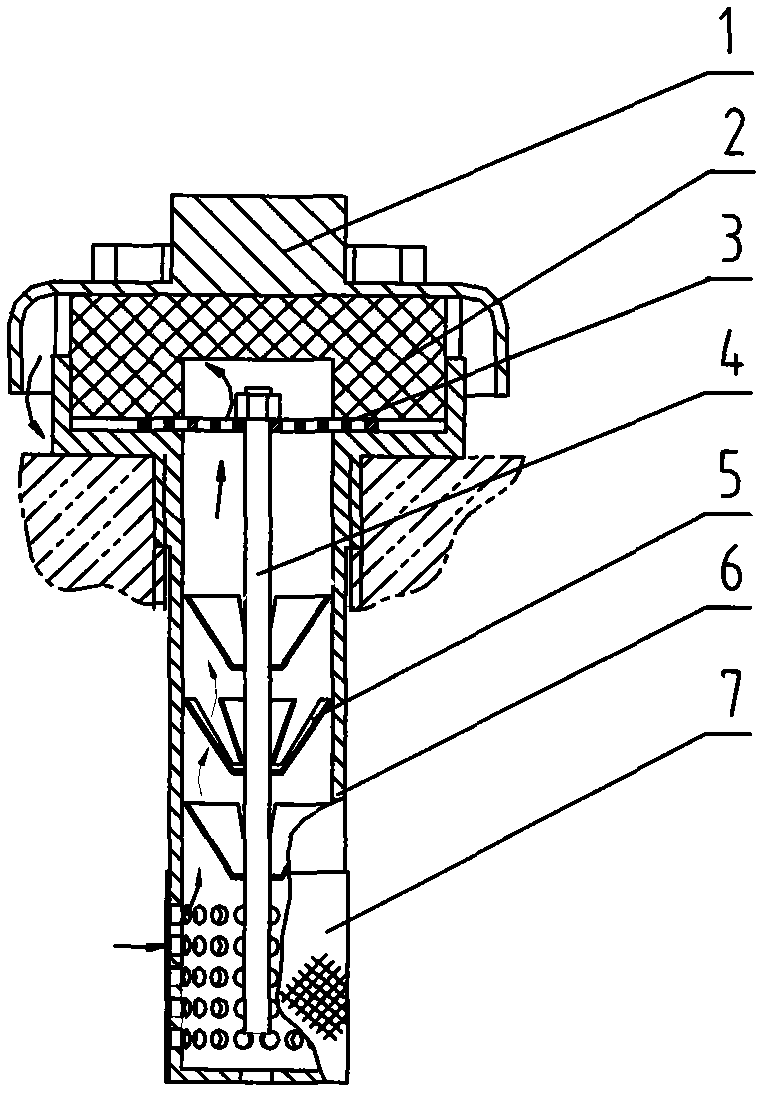

[0037] The respirator of the present invention can be used on the transmission case, and the respirator is fixed on the case body of the transmission case through threads (or flanges). The lower part of the respirator communicates with the interior of the transmission box, and the upper part communicates with the atmosphere outside the transmission box. The respirator is equipped with a filter element 2 inside, which can filter pollutant particles in the air and ensure that the liquid in the transmission box is not polluted.

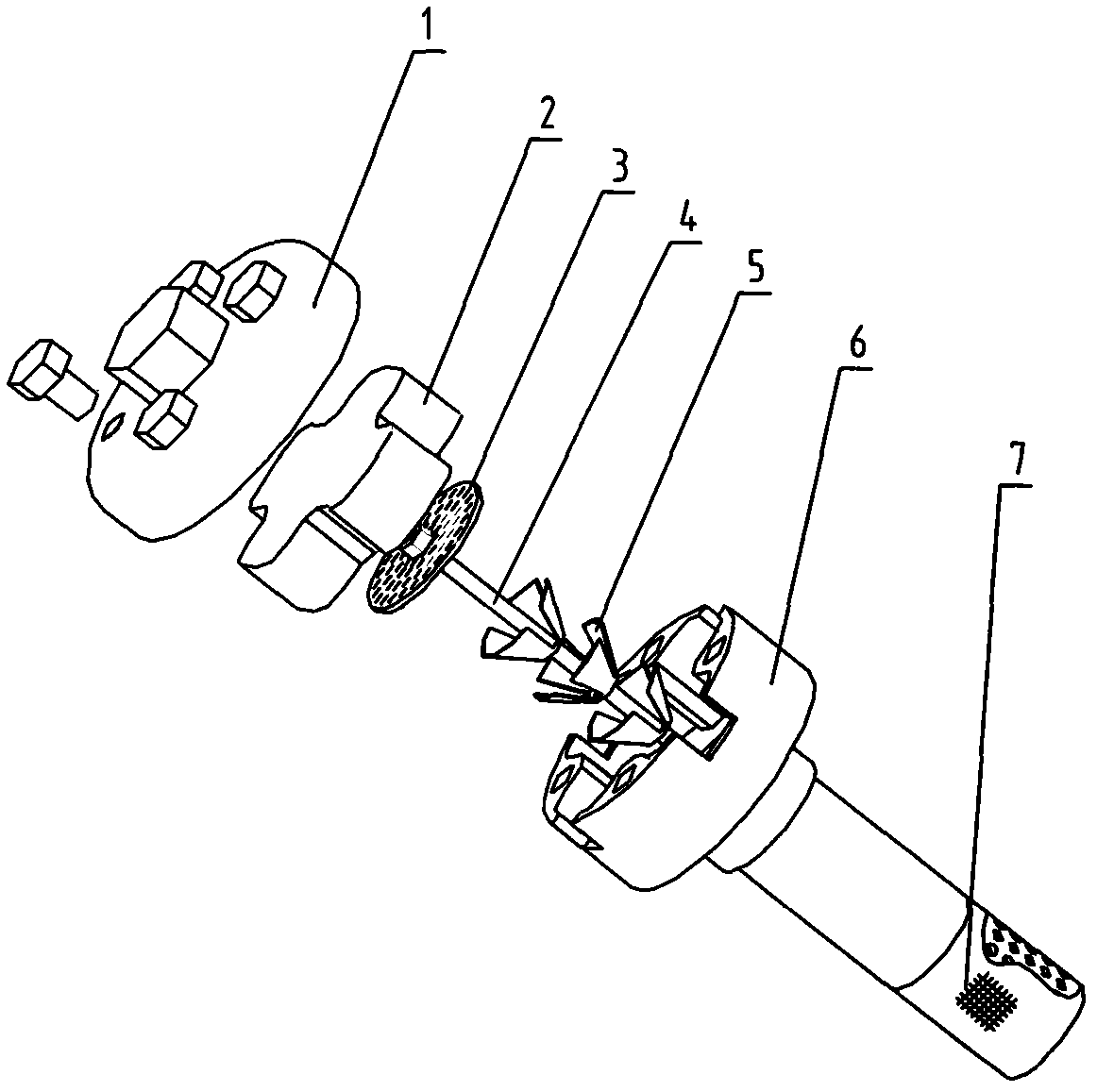

[0038] A respirator used for a transmission box of the present invention has a simple and practical structure. Its main components include: respirator cover 1, filter element 2, filter plate 3, positioning shaft 4, oil retainer 5, respirator body 6 and oil retainer 7, such as figure 1 shown. The filter plate 3 and the positioning shaft 4 are connected by threads and nuts, and the positioning shaft 4 and several oil baffles 5 are fixed together by means...

Embodiment 2

[0040] The oil mist or oil foam splashed due to the agitation of the gears in the transmission box first enters the interior of the respirator through the oil retaining net 7 and the rows of small holes in the lower part of the respirator body 6, such as figure 2 As shown, the fineness of the rows of small holes at the bottom of the respirator body 6 is 0.1mm-5mm. Oil retaining screen 7 and the rows of small holes at the bottom of respirator body 6 block most of the splashed oil outside the respirator, allowing air to enter. The oil retaining net 7 and the multi-row small holes at the bottom of the respirator body 6 can break most of the oil foam bubbles, and the oil of the broken oil foam will be blocked outside the respirator to allow air to enter. The oil retaining net 7 is made of metal wire It is composed of mesh or plastic mesh, and the fineness of metal mesh or plastic mesh is 0.01mm-5mm.

[0041] The gas entering the interior of the respirator moves upwards and encou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com