Method for detecting residual austenite in steel plate on line

A technology of residual austenite and detection method, which is applied in the field of detection, can solve the problems of inability to measure the carbon content of retained austenite, achieve the effects of shortening the measurement time, stabilizing the quality and reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

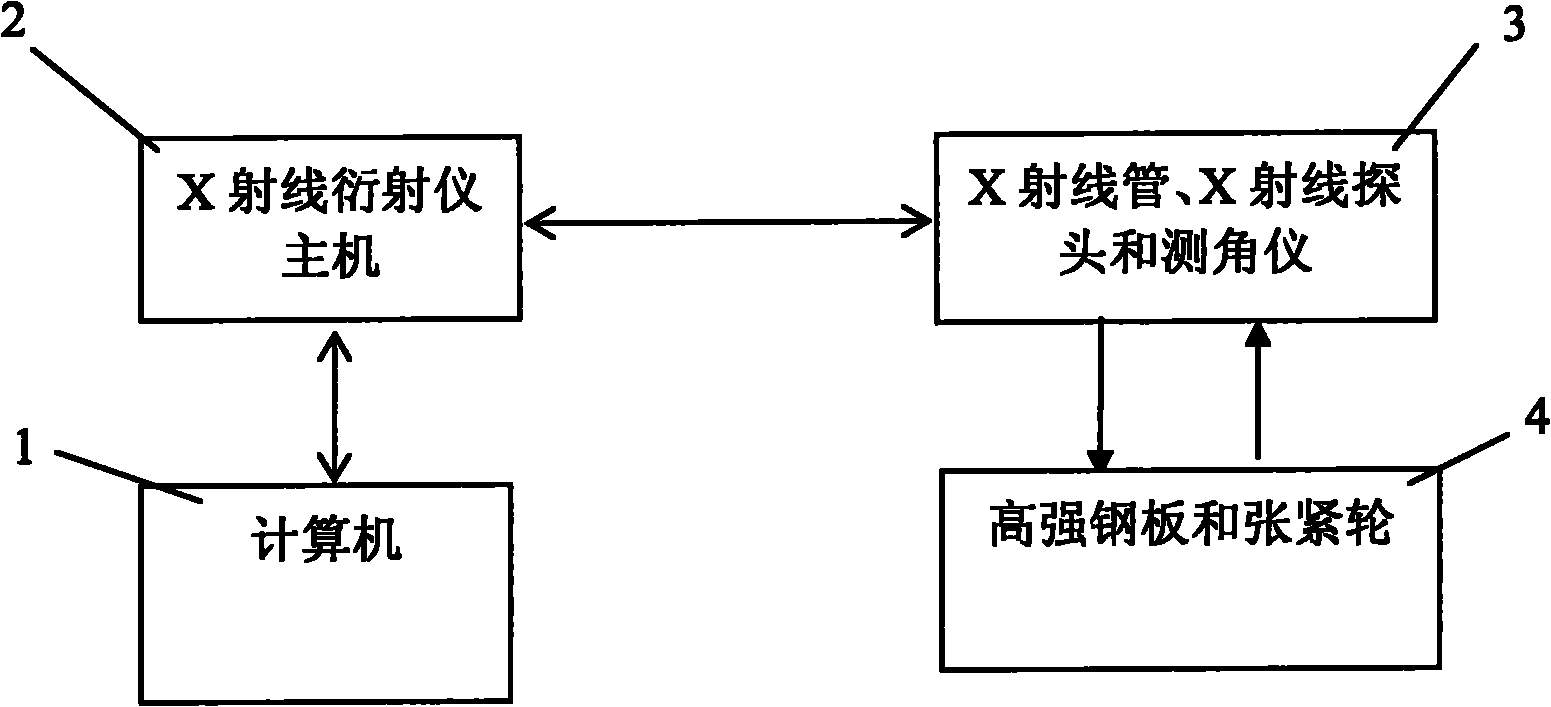

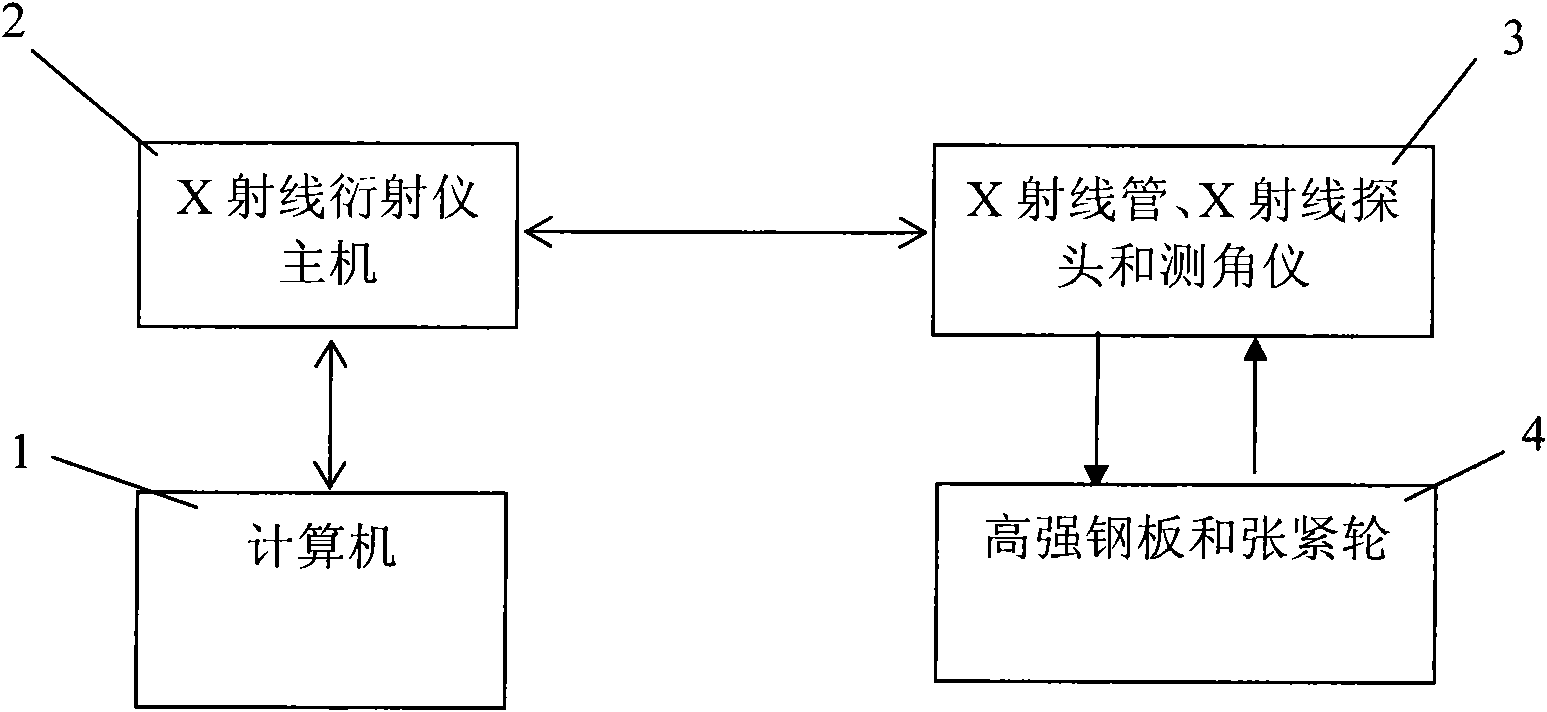

[0041] see figure 1 , the on-line detection method of residual austenite in the steel plate of the present invention, the computer 1 is mainly responsible for recording and processing the measurement data; the X-ray diffractometer host 2 provides high voltage for the X-ray tube and sends control commands to the goniometer 3; the X-ray tube Generate X-rays of a certain intensity, and the X-rays are irradiated through the slit to the surface 4 of the TRIP or Q&P high-strength steel strip running on the production line; the X-ray probe receives the X-ray diffraction signal generated on the surface of the steel strip.

[0042] 1) Test material

[0043] The thickness of the steel plate is about 1.2mm, and the test materials are TRIP and Q&P steel plates.

[0044] 2) Test process

[0045] (1) The running speed of the steel strip is controlled at 70-150 m / min;

[0046] (2) Adjust the distance between the X-ray tube, the X-ray probe and the steel strip surface, so as to be suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com