Anticreep carbon crystal heating fin for floor heating

An anti-leakage and heating chip technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve problems such as large leakage current, tripping, personal safety hazards, etc., and achieve the effect of convenient production, broad application prospects and simple modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

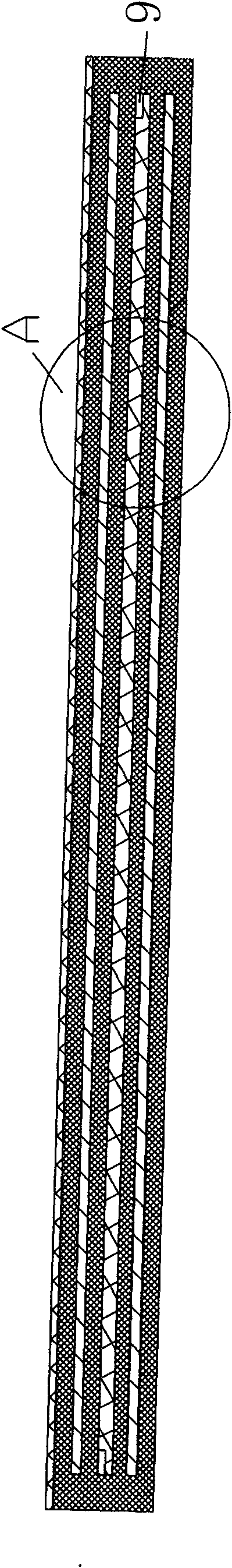

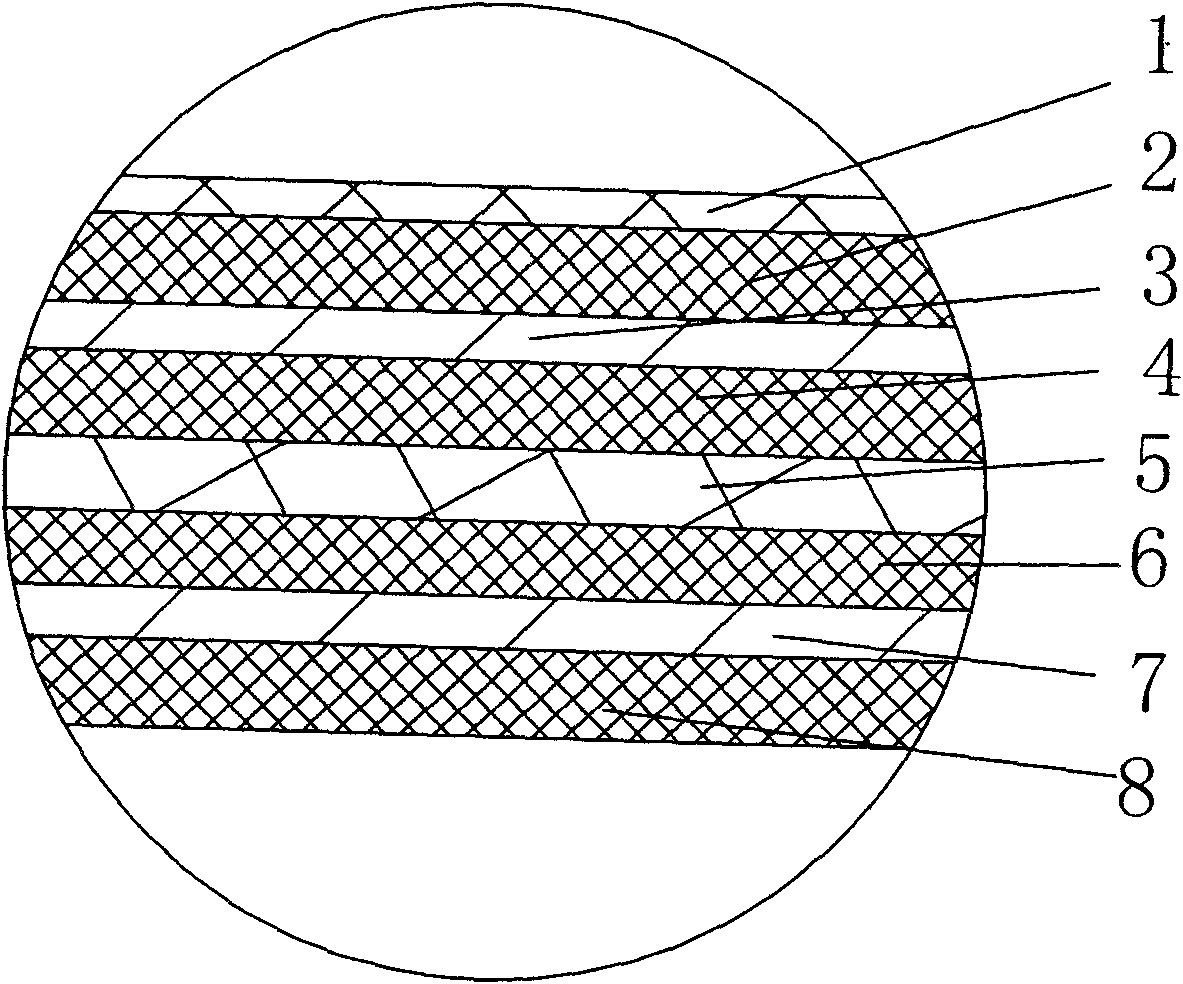

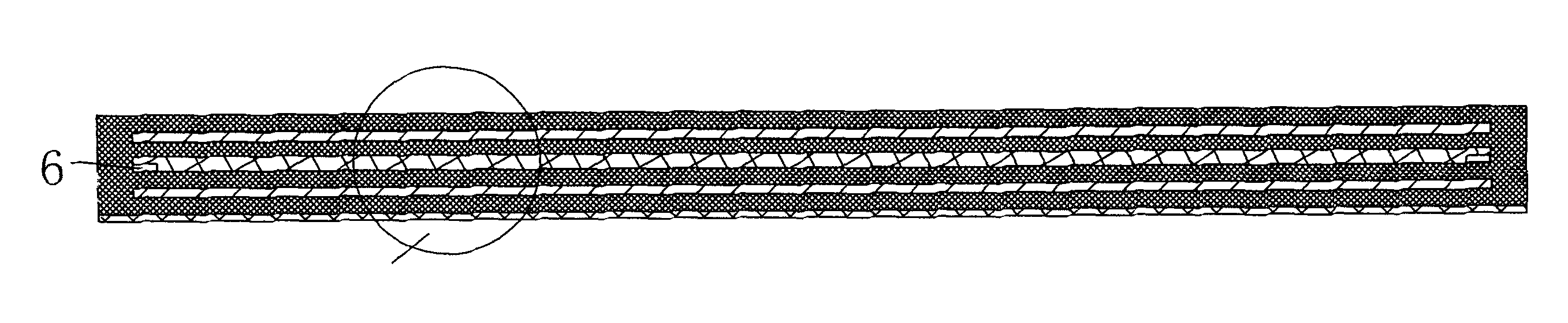

Image

Examples

Embodiment Construction

[0011] In the carbon crystal heating sheet of the present invention, the full name of the carbon crystal is carbon microcrystal, which is a crystal structure of carbon element. Carbon crystal and far-infrared emitter are mixed into carbon crystal conductive paste, which is printed or coated on the substrate, and after high-temperature drying and curing, it becomes a carbon crystal heating layer (usually the substrate is a flexible film); both ends of the carbon crystal heating layer After connecting the wires separately, it can be energized and heated. The electrothermal conversion rate of the carbon crystal heating sheet is as high as 99.8%, and 100% of the electrical energy input can be converted into about 65% of infrared radiation energy and 35% of conductive heat energy. In recent years, carbon crystal heating elements have become a new generation of heating elements.

[0012] After in-depth research, the applicant found that the reason for the leakage current of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com