Ethylene-vinyl acetate copolymer composition, ethylene-vinyl acetate copolymer film and method for producing same

A technology of ethylene vinyl acetate and copolymer film, which is applied in the direction of chemical instruments and methods, flat products, and other household appliances, and can solve the problems of high adhesion of EVA composition, low surface smoothness of EVA film, and difficulty in forming, etc. , to achieve the effects of excellent adhesion, excellent film-forming properties, and excellent film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

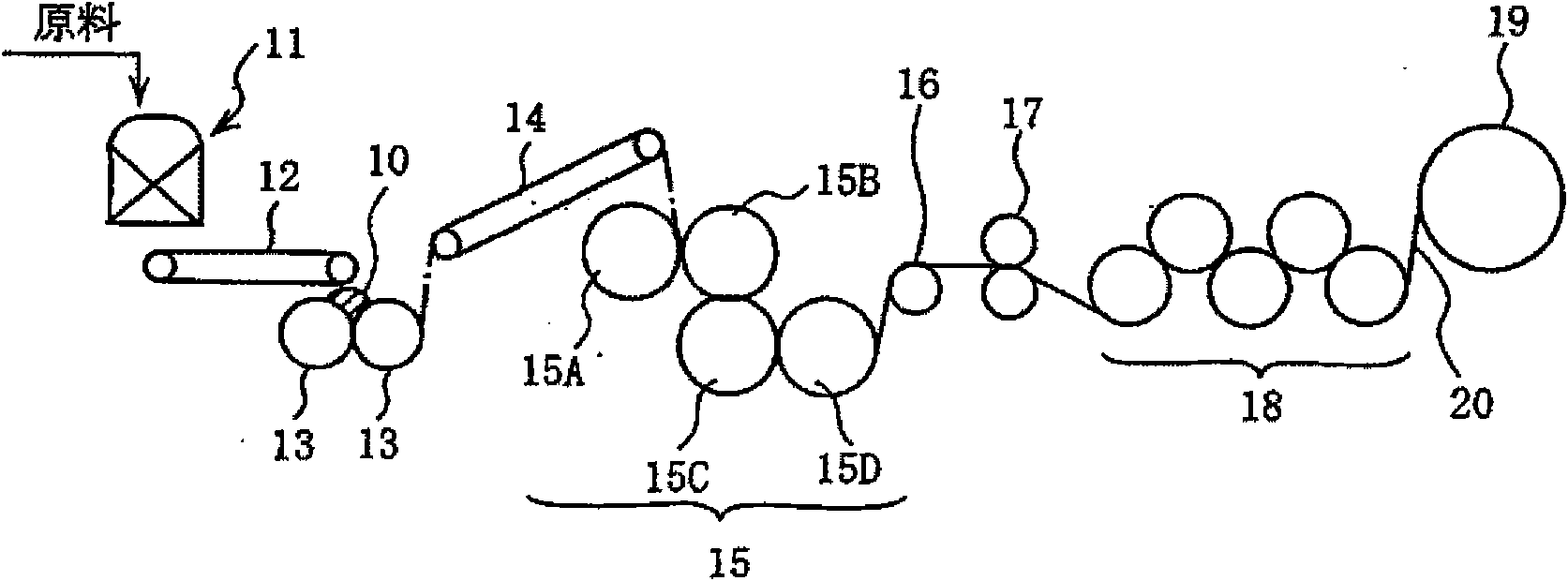

[0096] The EVA composition containing each material according to the following formulation was supplied to a roll mill, melted and kneaded at 60° C. for 10 minutes, and then calendered to produce an EVA film (thickness 0.4 mm). During calender molding, the temperature of the calender rolls was set at 64° C., and the rotational speed was set at 10 m / min.

[0097] The formulation of the EVA composition:

[0098] Ethylene-vinyl acetate copolymer (28 mass parts of vinyl acetate content relative to 100 mass parts of EVA) 100 mass parts

[0099] 3 parts by mass of crosslinking agent (tert-butyl peroxy-2-ethylhexyl carbonate)

[0100] 2 parts by mass of crosslinking aid (triallyl isocyanurate), and

[0101] Silane coupling agent (γ-methacryloxypropyltrimethoxysilane) 0.5 parts by mass

[0102] 0.01 parts by mass of lubricant (tri-n-octyl trimellitate).

Embodiment 2~5、 comparative example 1 and 2

[0104] Except having used the lubricant in the content shown in Table 1, it carried out similarly to Example 1, and produced the EVA film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com