Top modified transitional metal carbon hollow pipe material, and preparation method and application thereof

A transition metal and hollow tube technology, applied in the field of tobacco, can solve the problems of complex preparation methods and harsh preparation conditions, and achieve the effects of simple preparation methods, improved adsorption effect, and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

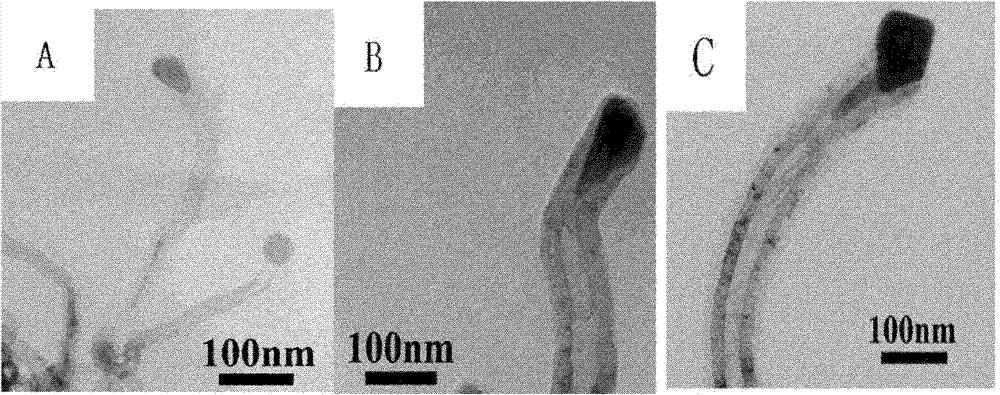

[0022] Synthesis of carbon hollow tubes modified with iron at the top: 25 grams of polyvinyl alcohol and 10 grams of ferric oxalate were uniformly mixed, placed in a stainless steel autoclave, sealed and placed in a high-temperature furnace. Keep at high temperature for 10 hours, after cooling to room temperature, first rinse with absolute ethanol, then rinse with distilled water to remove impurities, and then vacuum dry at 40°C for 4 hours to obtain a carbon hollow tube with iron modified on the top, the morphology is shown in figure 1 (A).

Embodiment 2

[0024] Synthesis of carbon hollow tubes modified with iron at the top: 50 grams of polyvinyl alcohol and 20 grams of ferric oxalate were uniformly mixed, placed in a stainless steel autoclave, sealed and placed in a high-temperature furnace. Keep at temperature for 15 hours, after cooling to room temperature, first rinse with absolute ethanol, then rinse with distilled water to remove impurities, and then vacuum dry at 40°C for 4 hours to obtain a carbon hollow tube with iron modified on the top.

Embodiment 3

[0026] Synthesis of carbon hollow tubes modified with iron at the top: 30 grams of polyethylene glycol and 12 grams of ferric oxalate were uniformly mixed, placed in a stainless steel autoclave, sealed and placed in a high-temperature furnace, heated from room temperature to 350 ° C within 30 minutes, and Keep at this temperature for 12 hours, after cooling to room temperature, first rinse with absolute ethanol, then rinse with distilled water to remove impurities, and then vacuum dry at 40°C for 4 hours to obtain a carbon hollow tube with iron-top modification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com