Method and device for reinforcing bridge by external pre-stressed strands under bridge

A technology of prestressed steel strands and external prestressing, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of hidden accidents, difficult construction, self-heavy and other problems, and achieve simple reinforcement structure, low reinforcement cost and high effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

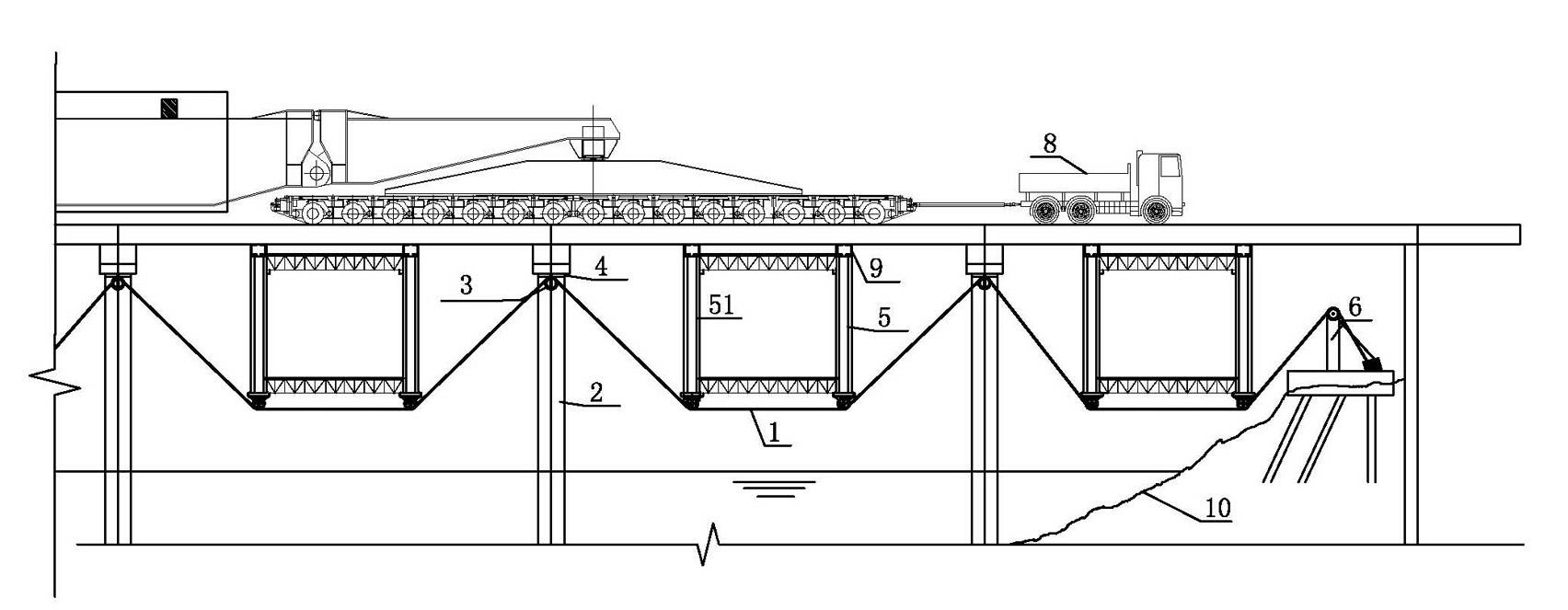

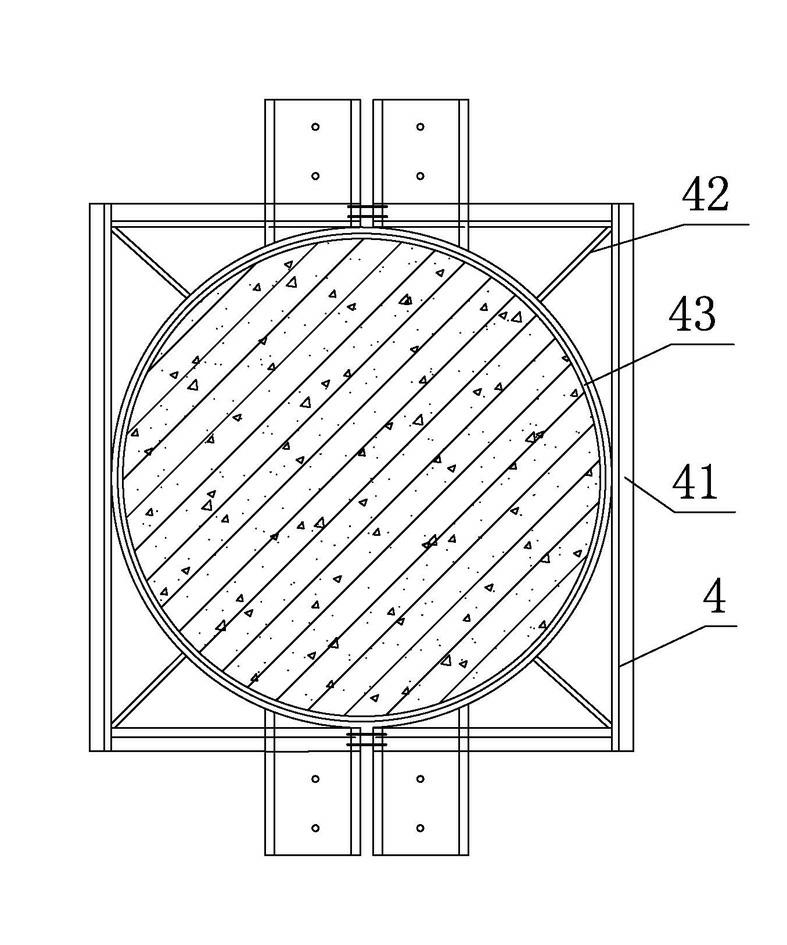

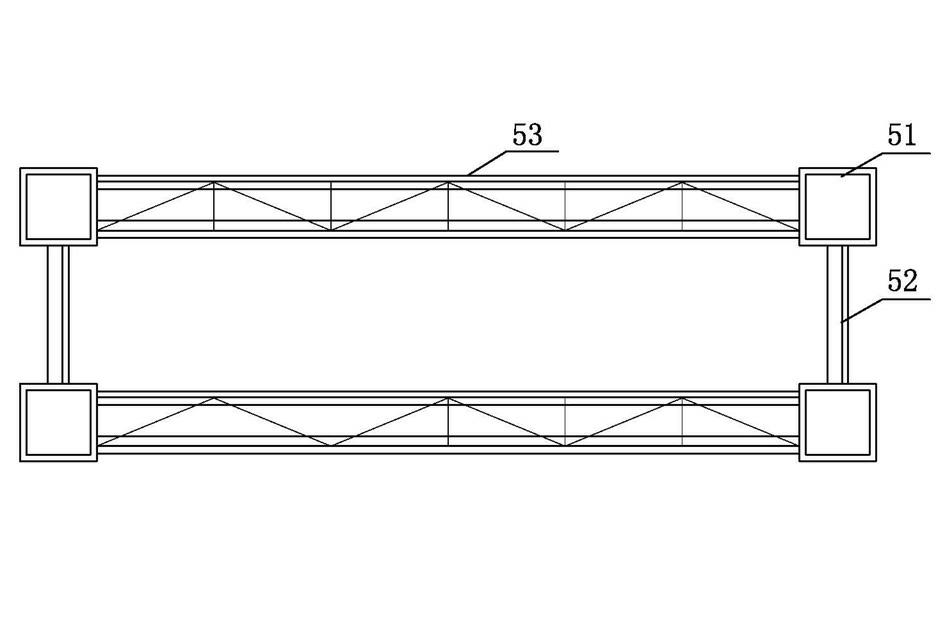

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings: the method for externally prestressed reinforced bridge under the bridge of the present invention, the method is: first install the steel hoop for fixing the prestressed steel strand on the top of the bridge pier , the steel hoop is lined with rubber sheets, and a small steel frame that can be tightly supported under the bridge deck is temporarily supported under the bridge deck between the two piers, and the prestressed steel strand is fixed on the steel hoop through a pulley, and then Fix it on the above-mentioned small steel frame, and finally fix the two ends of the prestressed steel strand on the tension support column and the support on the ground, and adjust the tension force of the prestressed steel strand to generate prestress Stretching, so that the small steel frame generates an upward lifting force on the bridge deck beam slab after being stressed.

[0016]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com