Method for improving excavating control characteristic and leveling operation characteristic of excavator

An operation characteristic and excavator technology, applied in the field of excavator operation control, improving excavator operation characteristics and leveling operation characteristics, can solve the inconsistency between the bucket speed and the composite movement of the boom and stick, and increase the design and adjustment of pipelines. Problems such as complexity and difficulty, occupying the limited control pipeline of the control valve, etc., achieve the effect of increasing the function of fast reciprocating motion, improving labor efficiency, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

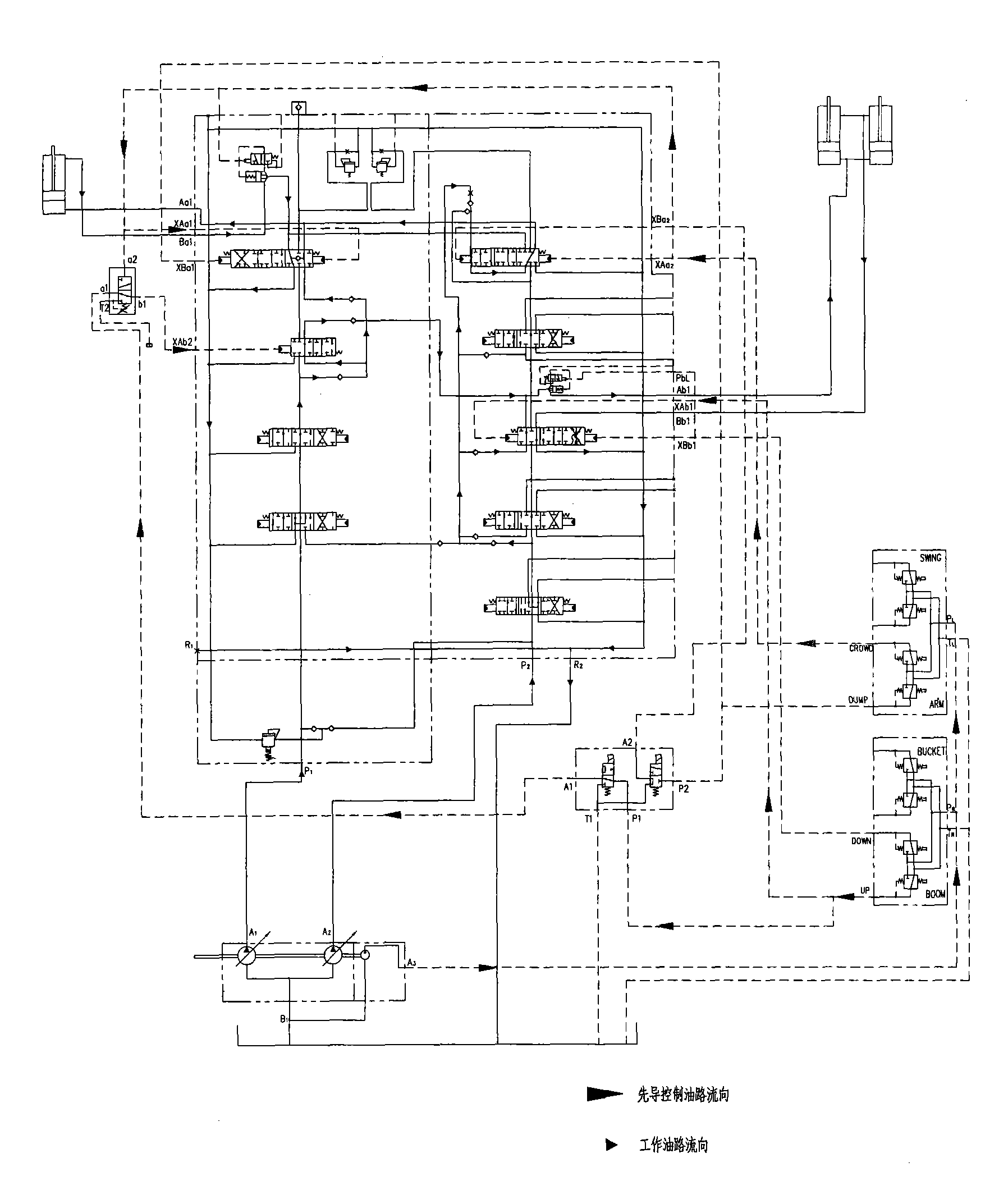

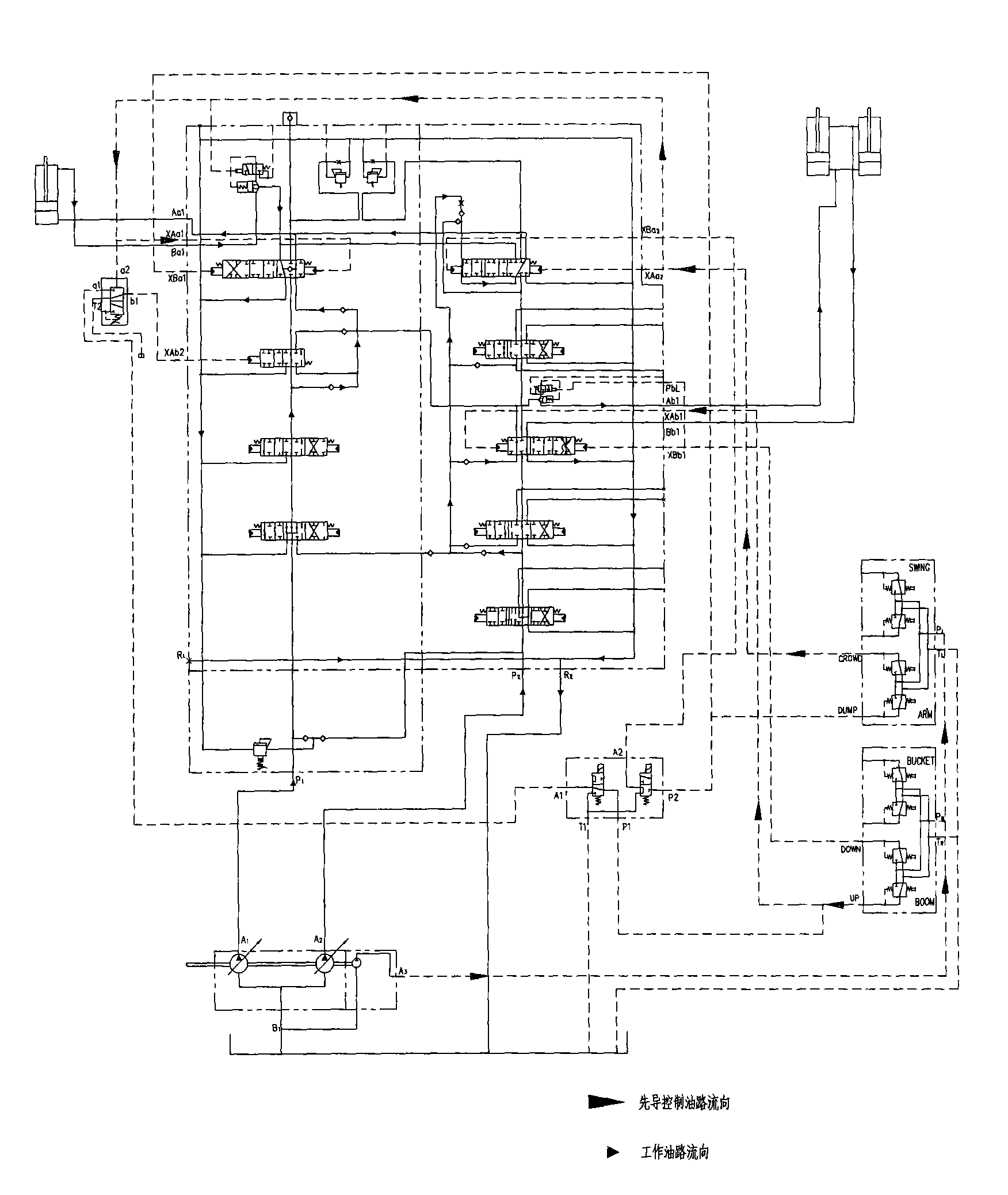

[0021] Embodiment one: if figure 1 , figure 2 and image 3 As shown, in the "standard excavation mode" when the hydraulic control reversing valve 7 is not reversing, the operator controls the right control handle valve 5 to connect the boom lifting pilot control circuit, and the hydraulic oil enters the right side from the hydraulic oil tank 3 through the gear pump 2. The control handle valve 5 is supplied to the oil control inlet port P1 of the solenoid valve group 4 through the BOOM UP port. At this time, the P1 oil circuit of the solenoid valve group 4 is connected to the oil control output port A1, and the pilot oil flows into the hydraulic control port through the oil control output port A1. Oil control input port a1 of reversing valve 7. Since the hydraulic control reversing valve 7 has not reached the pressure condition required for reversing at this time, the oil control input port a1 of the hydraulic control reversing valve 7 is connected with the oil control outpu...

Embodiment 2

[0025] Embodiment two: if figure 1 , Figure 4 and Figure 5 As shown, when entering the "leveling operation mode", the solenoid valve group 4 will change direction after receiving the direction change instruction signal.

[0026] When carrying out the compound action operation of boom lifting and stick digging, control the right control handle valve 5 to make the boom lifting pilot control circuit communicated, the hydraulic oil enters the control right control handle valve 5 from the hydraulic oil tank 3 through the gear pump 2, and then passes through From the BOOM UP end to the control end XAb1 of the multi-way valve group 8, the P of the double hydraulic pump 1 after the spool is reversed 2 Working oil is supplied independently to realize boom lifting (boom oil cylinder 10 stretches out). After the working oil in the rod cavity of the boom cylinder 10 flows back through the multi-way valve group 8, it passes through the R 2 The end returns to the hydraulic oil tank 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com