Method for electrical detection on wire harnesses of different sizes and universal test fixture

A technology for electrical testing and general testing, applied to parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of increasing the number of testing jig management personnel and management difficulty, occupying storage space, and eliminating the need for production costs, etc. To achieve the effect of simple and rapid detection process, improve efficiency and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

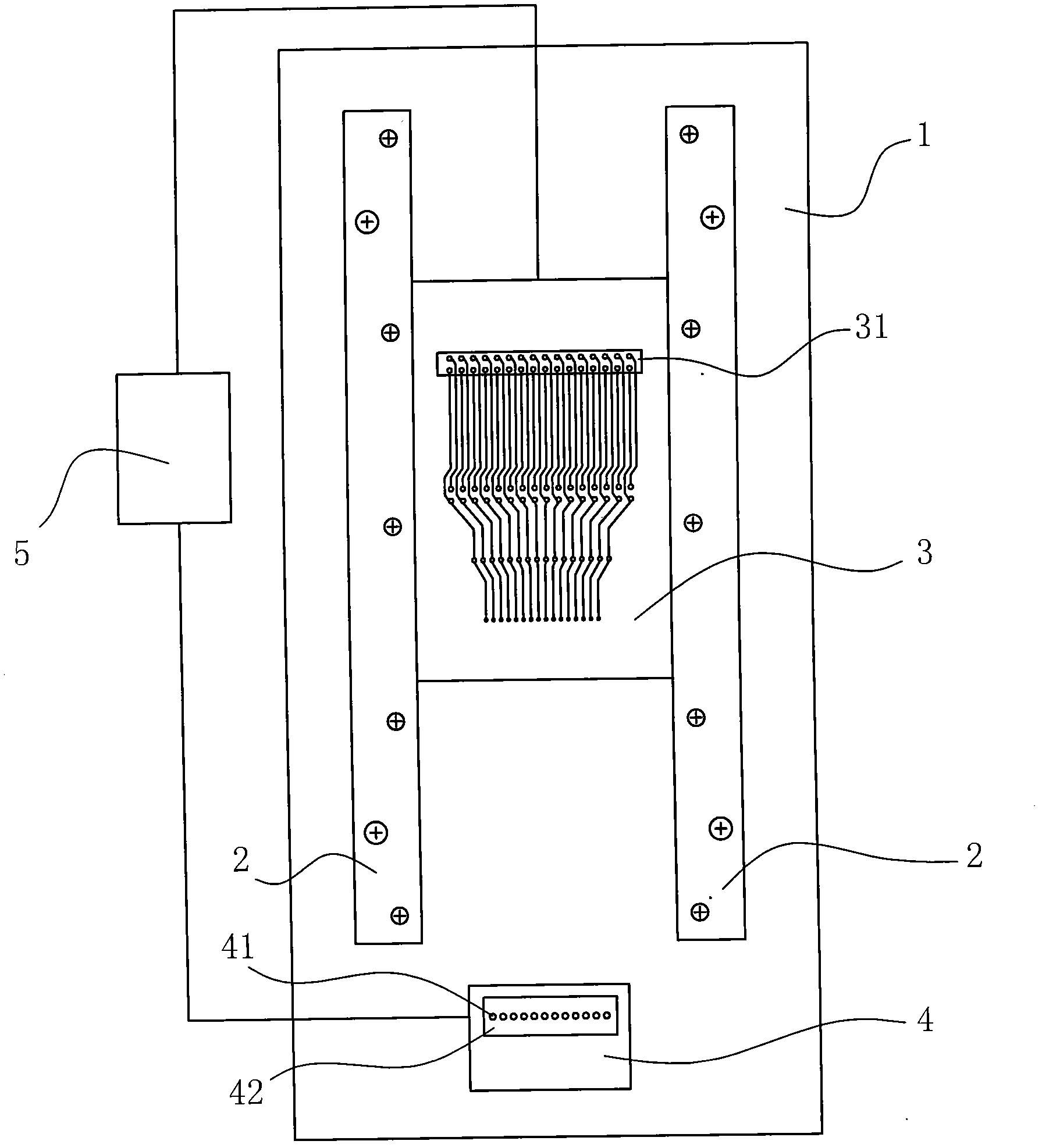

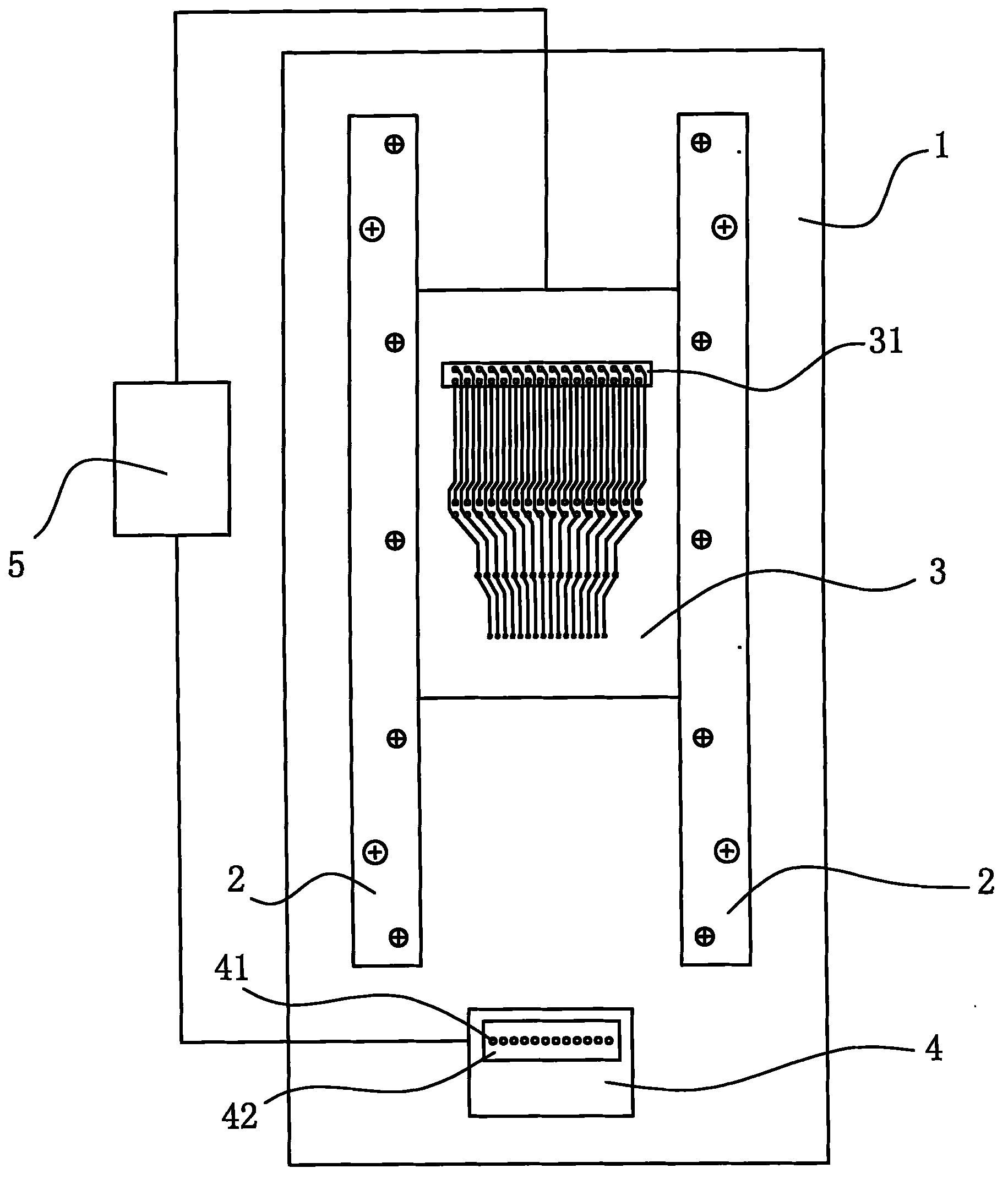

[0022] Example: see figure 1 , a method for electrical detection of wire harnesses of different specifications of the present invention, which comprises the following steps:

[0023] (1) Two slide rails 2 are arranged side by side on an installation and operation platform 1;

[0024] (2) Prepare a plurality of detection circuit boards 3, the size of the detection circuit boards 3 is the same, and a butt connector 31 is integrated on a detection circuit board 3 corresponding to the connector specification at one end of the wiring harness to be detected;

[0025] (3) Prepare an error-proof test device 4, and integrate a row of pins 41 in the error-proof test device 4. The pins 41 correspond to the jack-type connectors at the other end of the wire harnesses of different specifications, and can be used with a variety of different specifications. Jack connector docking;

[0026] (4) Select a corresponding detection circuit board 3 according to the wire harness connector specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com