Auxiliary detection device and method for ultraviolet laser interference fringe

An ultraviolet laser and auxiliary detection technology, which is applied in the exposure device, optics, and optical components of the photographic plate-making process. The effect of shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

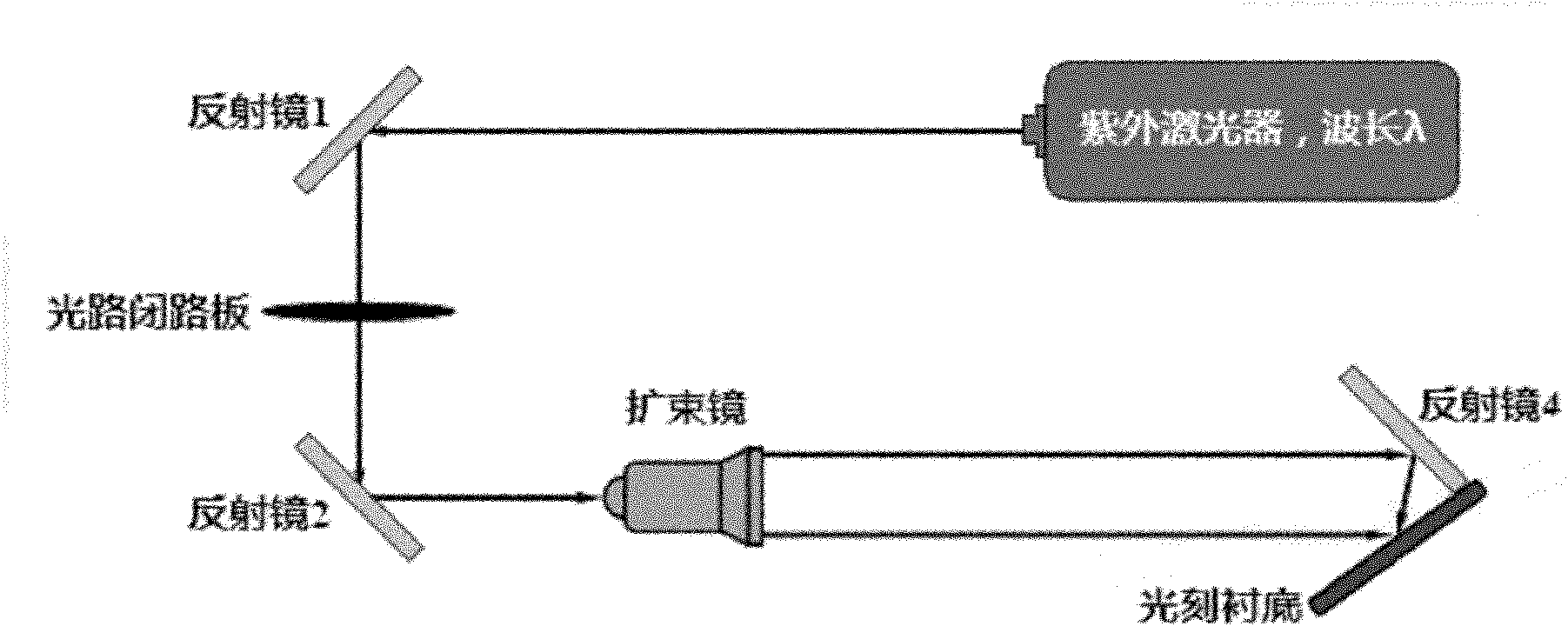

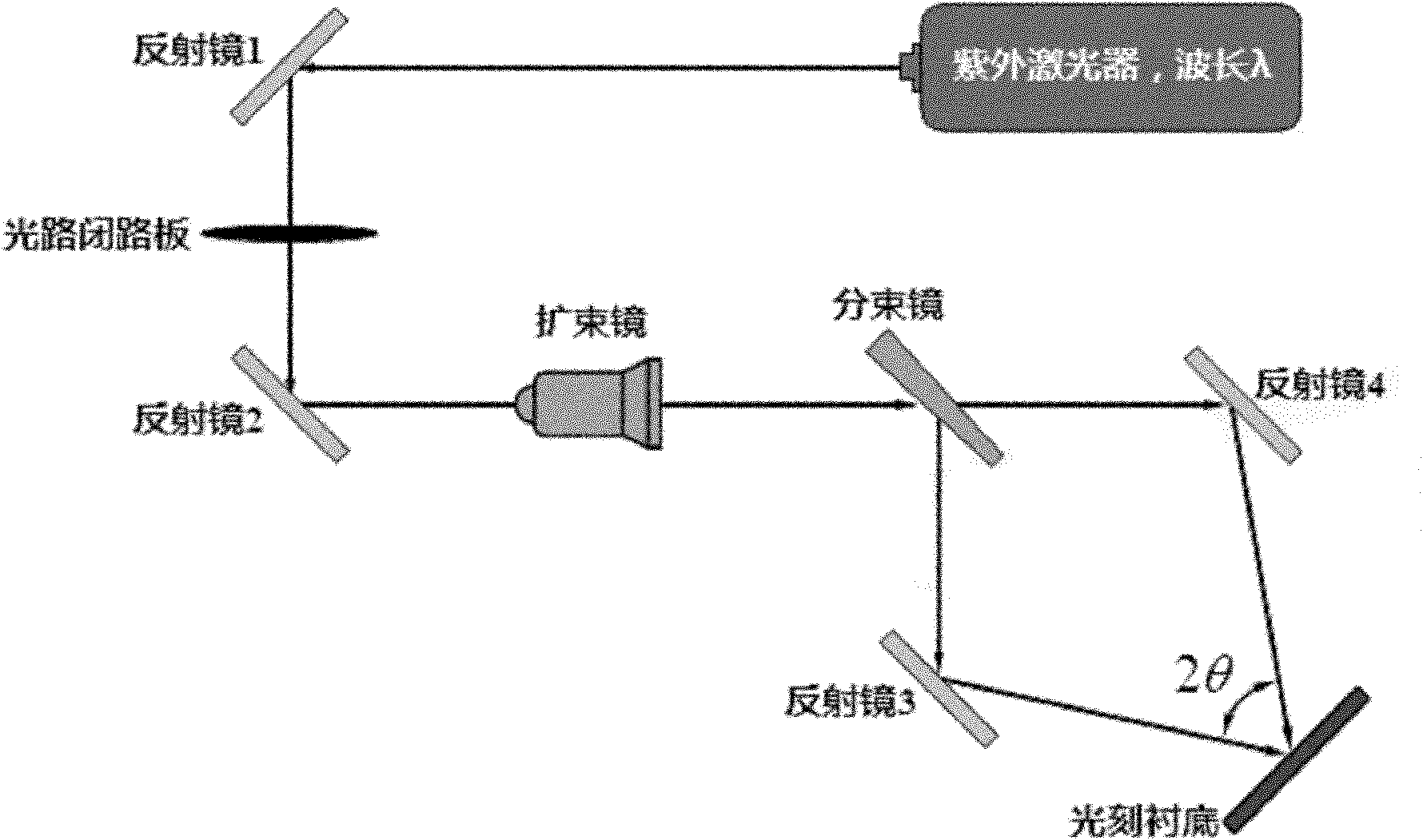

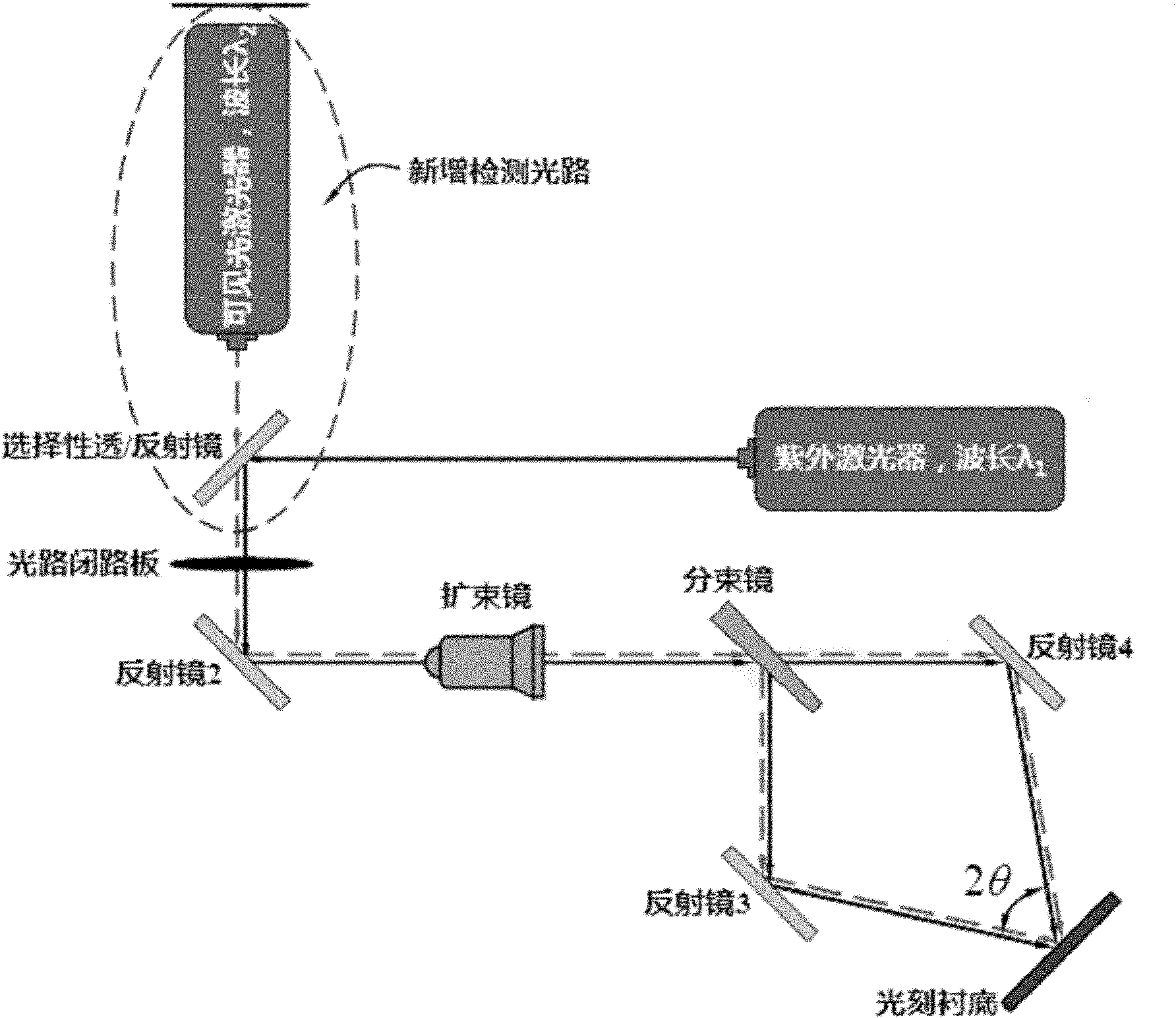

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

[0026] In an exemplary embodiment of the present invention, an auxiliary detection device for ultraviolet laser interference fringes is applied in an ultraviolet laser holographic lithography system, including: a visible light laser and an auxiliary detection optical path. The visible light laser is used to generate an auxiliary detection laser in the visible light band, and the wavelength of the auxiliary detection laser satisfies a preset relationship with the wavelength of the ultraviolet laser; the auxiliary detection optical path is used for the auxiliary detection laser in the ultraviolet laser holographic lithography system. Through the passage, the two sub-optical paths of the auxiliary detection optical path are respectively paralle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com