Polyester film and manufacturing method thereof

A technology of polyester film and manufacturing method, applied in the field of polyester film, can solve the problems of reducing MD shrinkage rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0060] The measured maximum shrinkage stress: 10N (1.02kg=10 / 9.8kg)

[0061] Sample cross-sectional area: 1.5mm 2 (width 15mm, thickness 100μm)

[0062] Maximum shrinkage stress (kg / mm 2 ): 1.02kg / 1.5mm 2 =0.68kg / mm 2

[0063] 3) Tensile Strength / Elongation

[0064] Films were provided with a width of 15 mm, a gauge length of 50 mm, and a cross heating rate of 500 mm / min. The tensile properties of the films in MD and TD were measured using a multifunctional tensile testing machine (Instron, Tensile Test Machine).

[0065] 4) Evaluation of optical properties (haze measurement)

[0066] Haze measurements are based on ASTM D-1003. Seven sections including two edge sections and a center section were arbitrarily extracted from the polyester film. Next, the sections were cut from the sample to a size of 5 cm x 5 cm and inserted into a haze measurement system (Nippon Denshoku NDH 300A). Then, light having a wavelength of 555 nm was injected into the system, after which the ...

example 1

[0070] First, 100 mol% of terephthalic acid, 124 mol% of ethylene glycol as a diol component, and 0.05 mol of antimony trioxide as a catalyst based on an acid component were polycondensed by direct esterification to obtain an intrinsic viscosity of 0.64 dl / g of polyester, followed by polyester having an intrinsic viscosity of 0.64 dl / g was melt extruded at 275°C, followed by rapid cooling to provide a non-oriented sheet.

[0071] The non-oriented sheet is preheated by a set of rollers conveyed on the MD (MDO, Machine Direction Organization, longitudinal mechanism), and then, continuously, is oriented to 2.5 times by an IR heater zone heated to 760°C, Oriented by a factor of 1.3 by an IR heater zone heated to 650°C. Thus, the sheet was oriented in the MD with a total MD orientation of 3.25 times.

[0072] Immediately after MD orientation, the sheet was conveyed to a tenter frame, passed continuously through a preheat zone at 125°C, TD oriented to 3.5 times at 150°C, and then h...

example 2-4

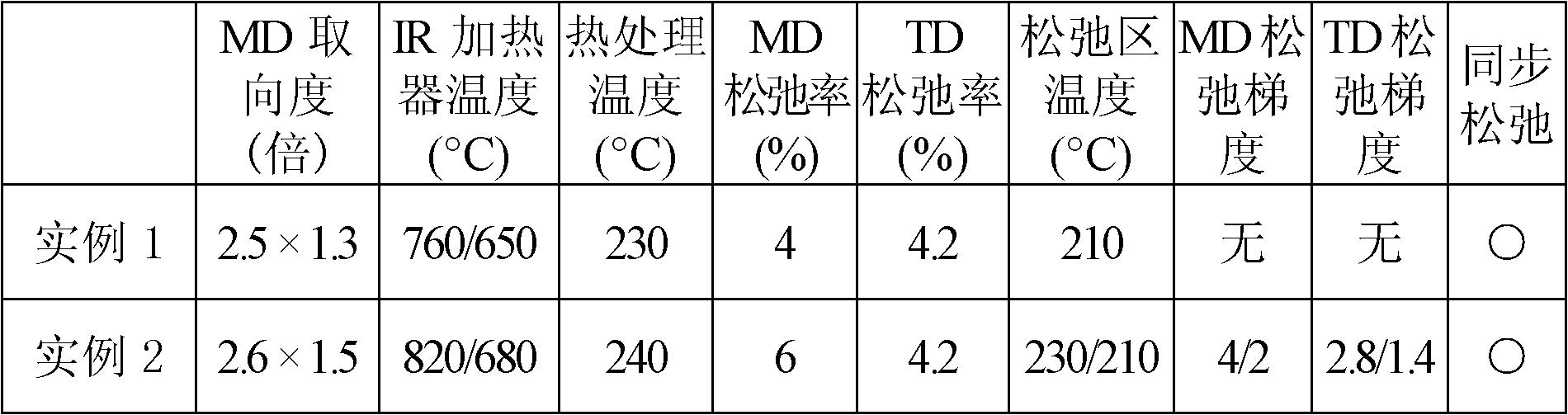

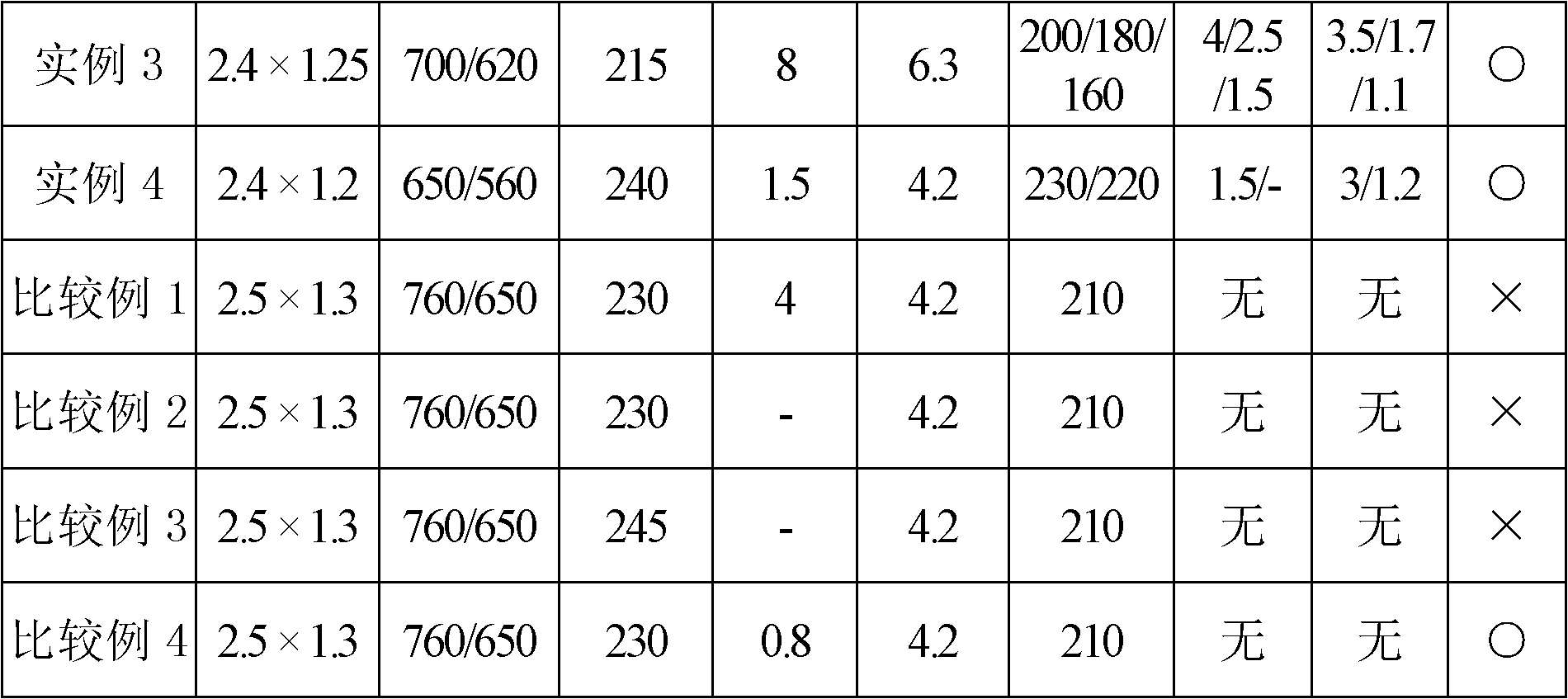

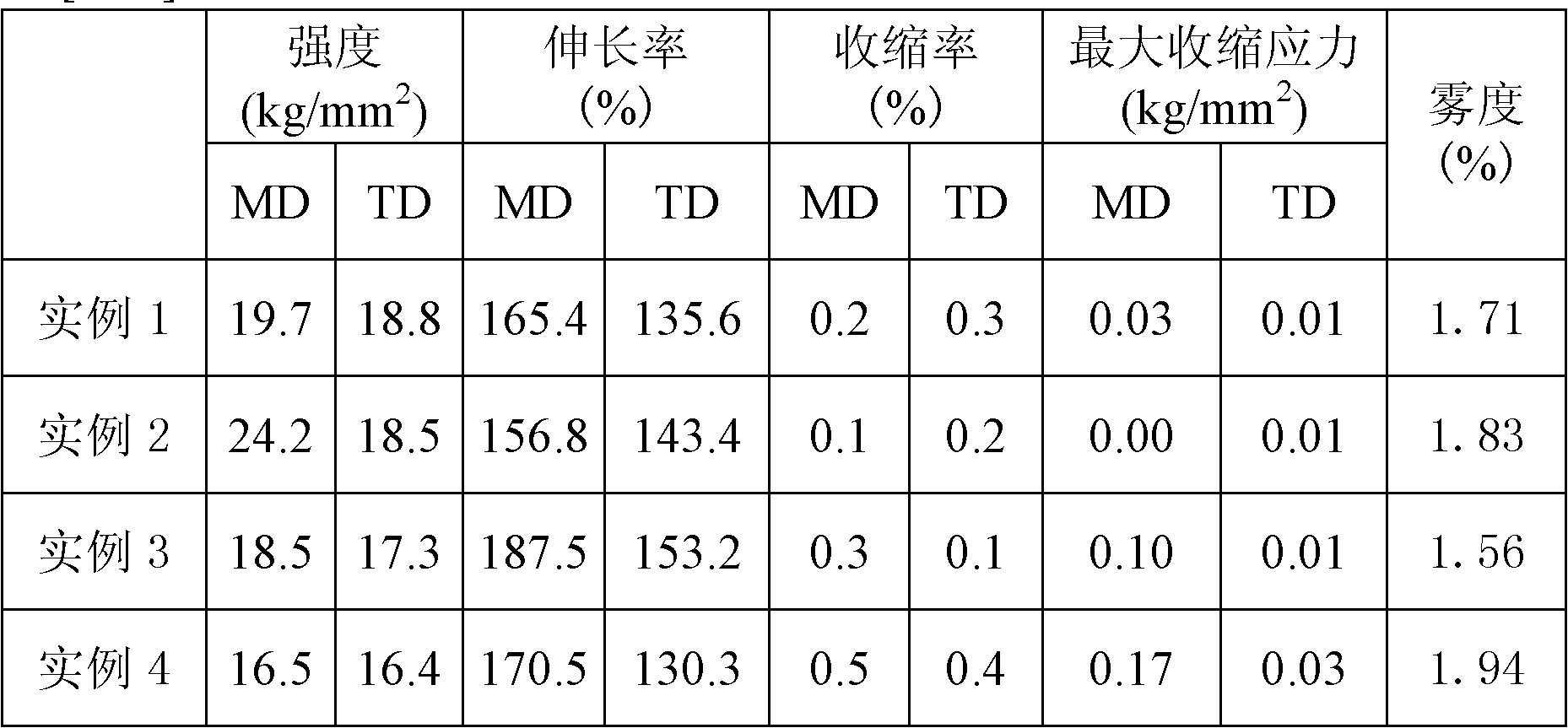

[0075] Except changing the MD orientation degree, IR heater zone temperature, heat treatment temperature, MD relaxation rate, TD relaxation rate, number of relaxation zones, relaxation temperature and MD / TD relaxation gradient in the relaxation zone, the same method as described in Example 1 The method obtains non-oriented sheets and thus obtains different films. The changed conditions are shown in Table 1 in detail. The properties of the films are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear shrinkage | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com