a thermoplastic composition

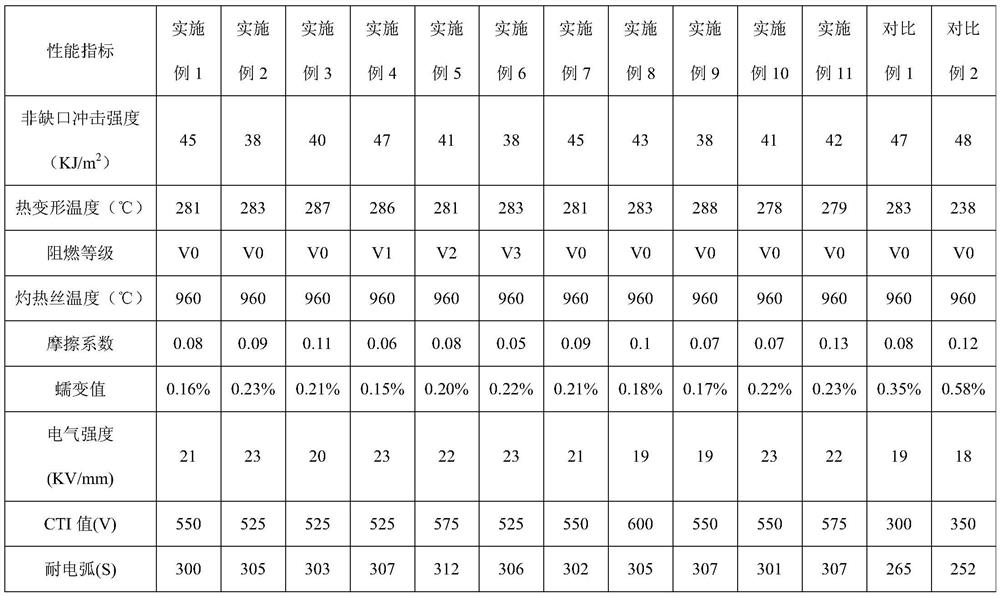

A technology of thermoplastic composition and thermoplastic resin, which is applied in the field of thermoplastic composition, can solve problems such as poor CTI value and arc resistance, limit the application of thermoplastic materials, and poor dimensional stability at high temperature, so as to save manual trimming process and flame retardancy Excellent performance and high temperature dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

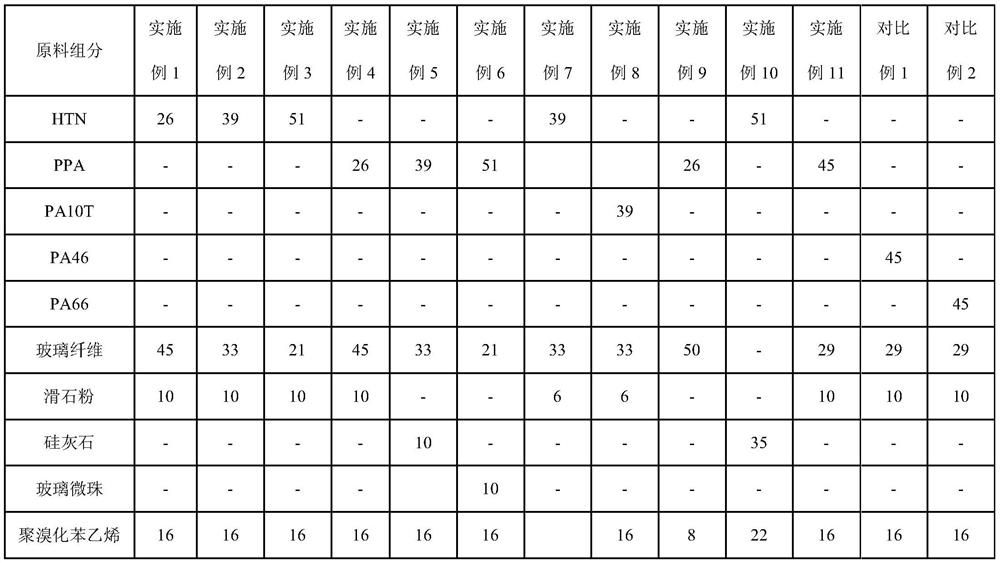

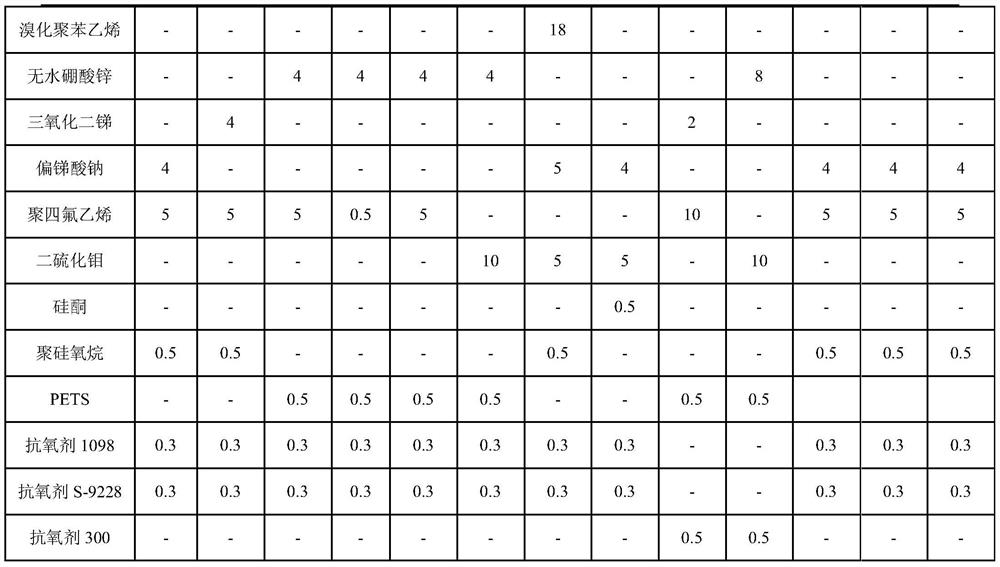

[0038] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0039] Examples of raw materials

[0040] HTN resin, melting point Tm=305°C, glass transition temperature Tg=135°C, water absorption=0.43%;

[0041] PPA resin, melting point Tm=310°C, glass transition temperature Tg=124°C, water absorption=0.24%;

[0042] PA10T resin, melting point Tm=316°C, glass transition temperature Tg=135°C, water absorption=0.12%;

[0043] PA46 resin, melting point Tm=290°C, glass transition temperature Tg=78°C, water absorption=3.7%;

[0044] PA66 resin, melting point Tm=262°C, glass transition temperature Tg=47°C, water absorption=1.3%;

[0045] Glass fiber: short glass fiber with a diameter of 5-23 μm;

[0046] Inorganic mineral powder: talcum powder, wollastonite, glass microspheres;

[0047...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com