A kind of polyaryl sulfone amide-based porous membrane and its preparation method and application

A technology of polyarylsulfone amide and porous membrane, applied in polyarylsulfone amide-based porous membrane and its preparation method and application, in the field of chemical industry, to achieve the effects of uniform pore size distribution, excellent flame retardancy, and high temperature dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

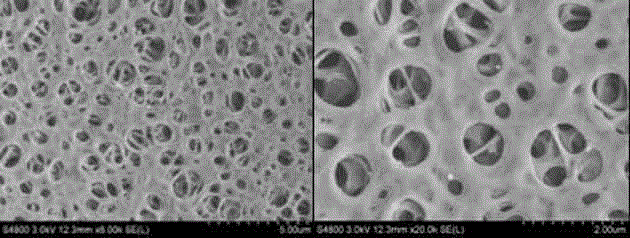

Image

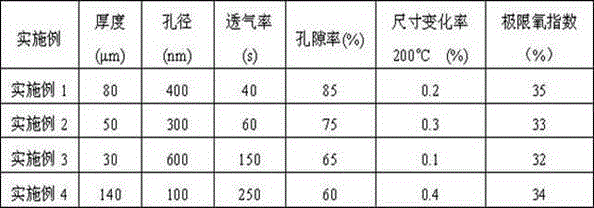

Examples

Embodiment 1

[0014] Add 6 g of polyarylsulfone amide, 1.5 g of n-butanol and 22.5 g of N, N-dimethylacetamide into a 100 mL reagent bottle, stir at 75 °C for 3 h, and prepare a uniform polyarylsulfone amide solution (casting solution), pour the obtained casting solution on a glass plate, and scrape it with a 300 μm scraper to form a solution film. After standing for a while, the glass plate with the solution membrane was immersed in a 75°C deionized water coagulation bath for 3 min to solidify and regenerate to obtain a polyarylsulfoneamide porous membrane.

Embodiment 2

[0016] Add 4.5 g of polyarylsulfoneamide, 1.5 g of polyvinylidene fluoride-hexafluoropropylene, 3 g of ethanol and 21 g of N-methylpyrrolidone into a 100 mL reagent bottle, stir at 60 °C for 5 h, and prepare a homogeneous mixed solution (casting solution). The obtained casting solution was poured onto a glass plate, and scraped with a 200 μm scraper to form a solution film. After standing still for a while, the above-mentioned glass plate with the solution membrane was immersed in a 30 °C methanol coagulation bath for 20 min to solidify and regenerate to obtain a polyarylsulfoneamide / polyvinylidene fluoride-hexafluoropropylene porous membrane.

Embodiment 3

[0018] Add 3 g polyarylsulfoneamide, 3 g polymethyl methacrylate, 4.5 g glycerol and 19.5 g tetrahydrofuran into a 100 mL reagent bottle, stir at 40 °C for 7 h, and prepare a uniform mixed solution (cast membrane fluid). The obtained casting solution was poured onto a glass plate, and scraped with a 400 μm scraper to form a solution film. After standing still for a while, the glass plate with the solution membrane was immersed in a 45 °C diethyl ether coagulation bath for 40 min to solidify and regenerate to obtain a polyaryl sulfone amide / polymethyl methacrylate porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com