Device and method for joint test of electric arc current density distribution and electric arc pressure distribution

A density distribution, arc current technology, used in arc welding equipment, manufacturing tools, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

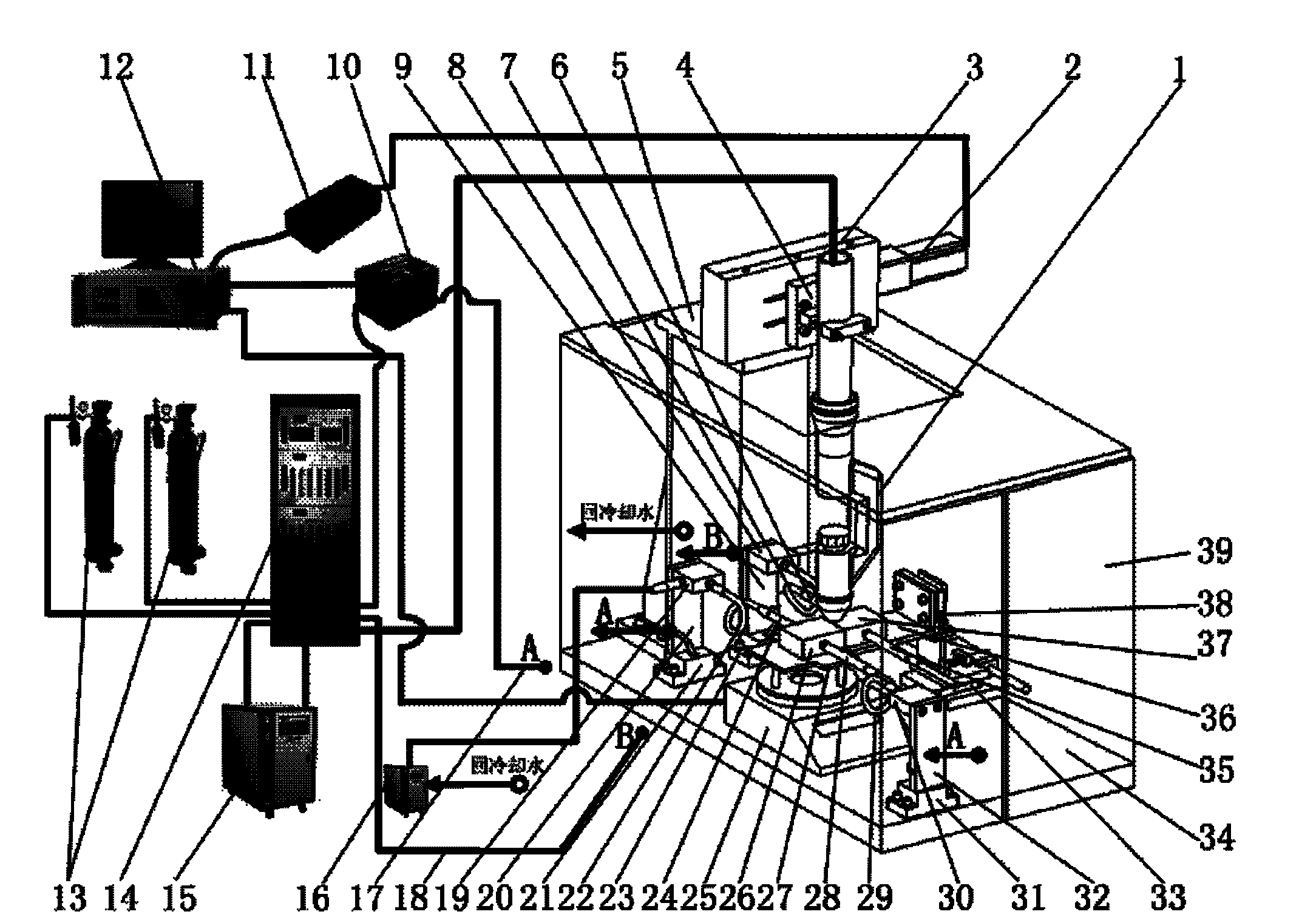

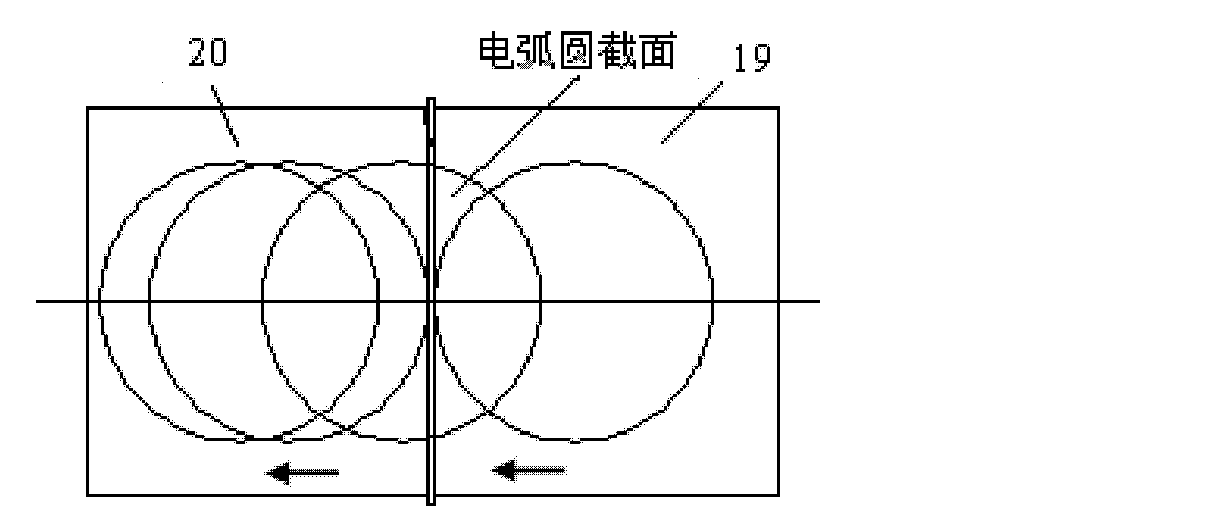

[0060] Concrete operation process of the present invention is described in detail in conjunction with accompanying drawing: as figure 1 As shown, the device of the present invention includes: a workbench 34, a support column 5 positioned on the workbench 34, a screw guide rail slider mechanism 3 fixed on the support column 5, a motor 2 connected to the lead screw, and a connecting plate 4 , the welding gun 1 fixed on the slider through the connecting plate 4, the three-dimensional adjustment mechanism 38 fixed on the workbench 34, the insulating support plate 36 fixed on the three-dimensional adjustment mechanism 38, and the right anode plate placed on the insulating support plate 36 37, the load cell 25 located on the workbench 34, the insulating support frame 27 and the left anode plate 26 placed on the load cell 25, the insulation seat I21, the insulation seat II23, and the insulation seat III31 fixed on the workbench 34, The aluminum support plate I20 fixed on the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com