Fully automatic feeding, cutting and receiving equipment and its processing method

A fully automatic, material feeding technology, which is applied in other manufacturing equipment/tools, metal processing, metal processing equipment, etc., can solve the problems of unguaranteed material utilization rate, heavy clamping device, waste of resources, etc., to ensure material utilization rate, The effect of saving manpower and material resources and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

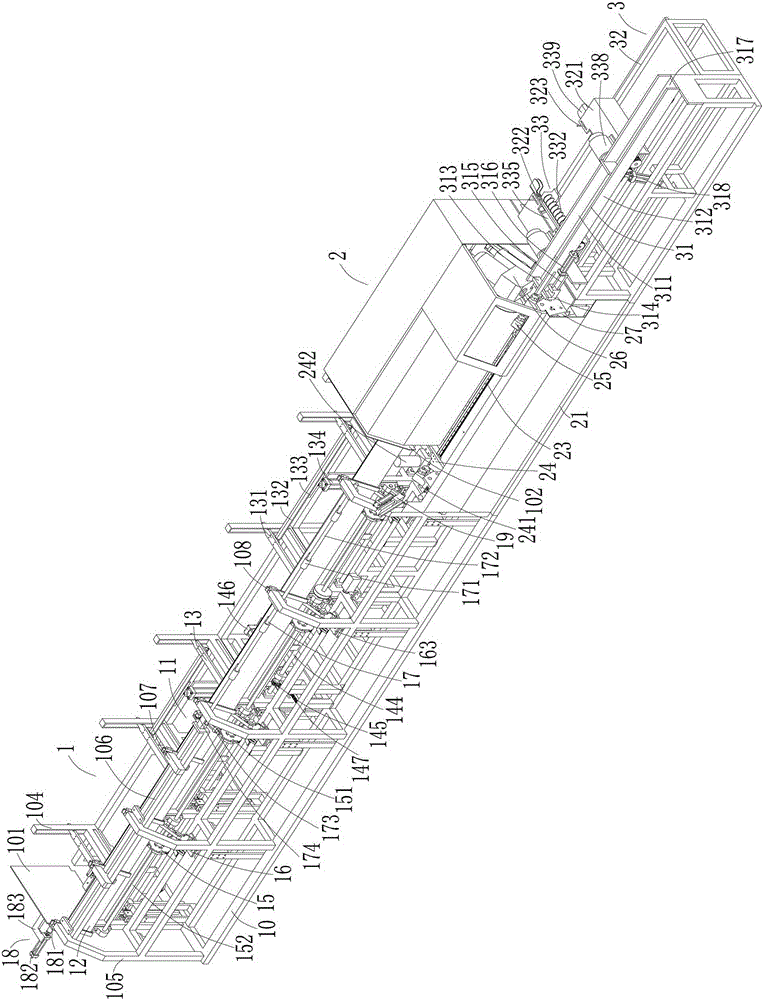

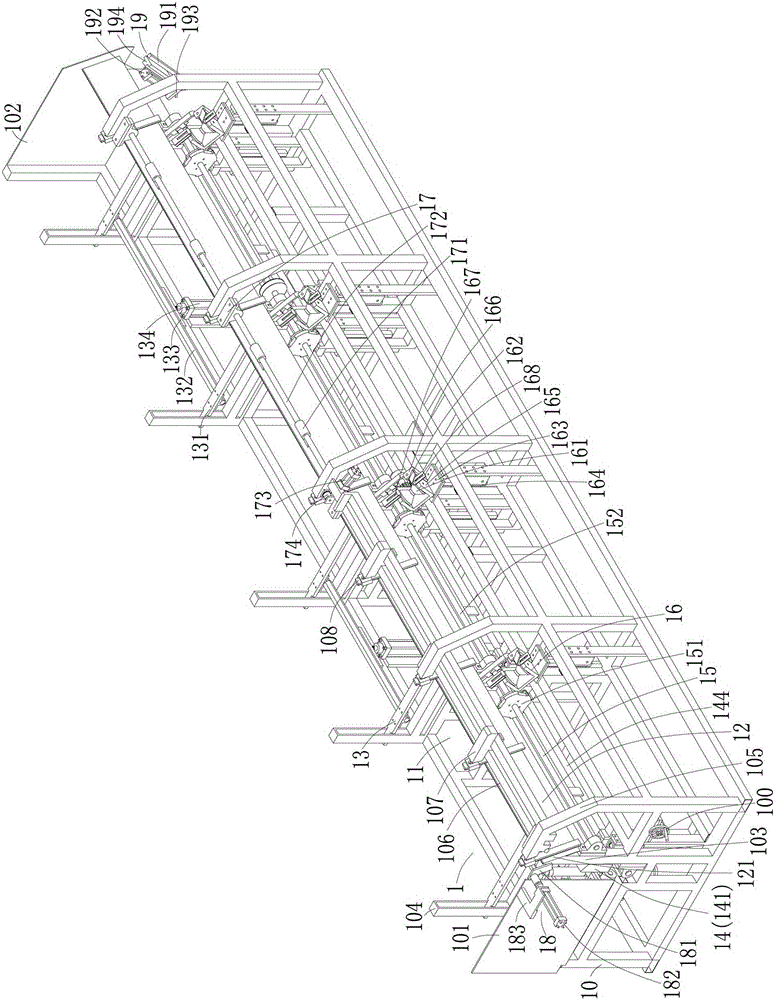

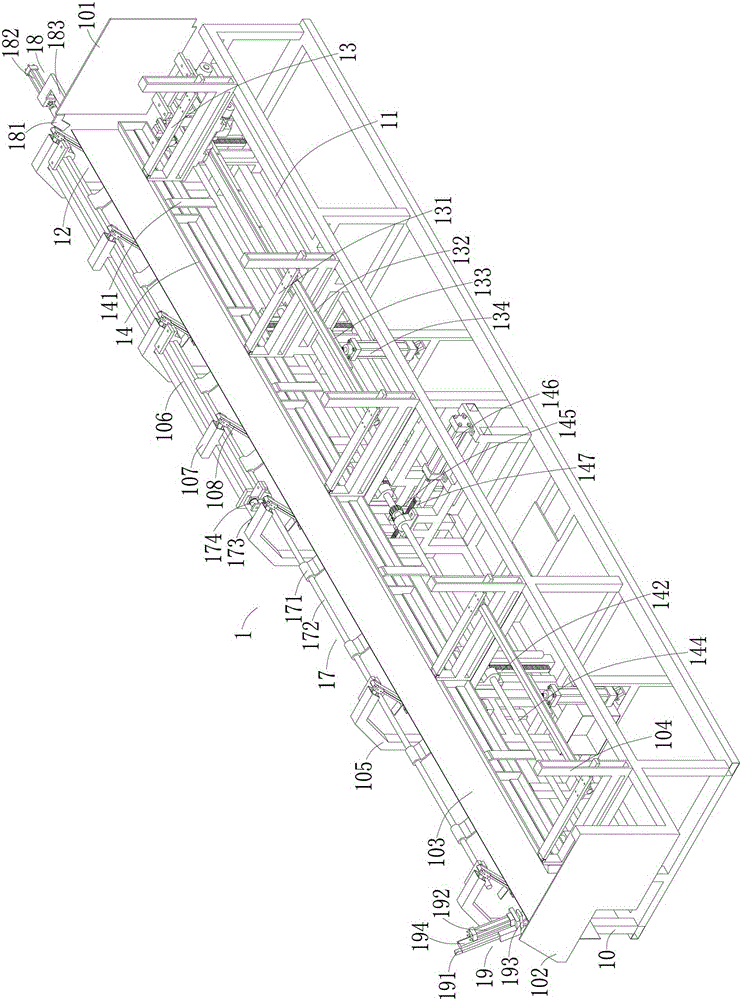

[0058] see Figure 1-10 As shown, the present invention relates to a fully automatic feeding, cutting and receiving equipment, which is composed of a feeding device 1, a pipe cutting device 2 and a recovery device 3 connected in sequence, and the feeding bracket 10 of the feeding device 1 is provided with a storage tank 11. Material trough 12, ejecting mechanism 13, pushing mechanism 14, material distributing mechanism 15 and unloading mechanism 16, the pipe cutting guide rail 23 at the front end of the hydraulic center 22 on the pipe cutting support 21 of the pipe cutting device 2 is provided with The feeding trolley 24 is provided with a split fixture 25 on one side of the pipe cutting guide rail 23, and the split fixture 25 and its rear end are provided with a pipe cutter 26. 172 is composed of a material shifting mechanism 17, and an alignment mechanism 18 is arranged at one end of the rear baffle plate 101 of the material feeding device 1 corresponding to the material shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com