High-efficiency and large-power vertical axis wind power generator

A wind turbine, vertical axis technology, applied in wind turbine components, wind turbines, wind turbine combinations, etc., can solve the problems of large wind energy loss, high blade damage rate, and poor wind resistance of the diversion device, and achieve the combination of Simple processing, high forming precision and strong wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

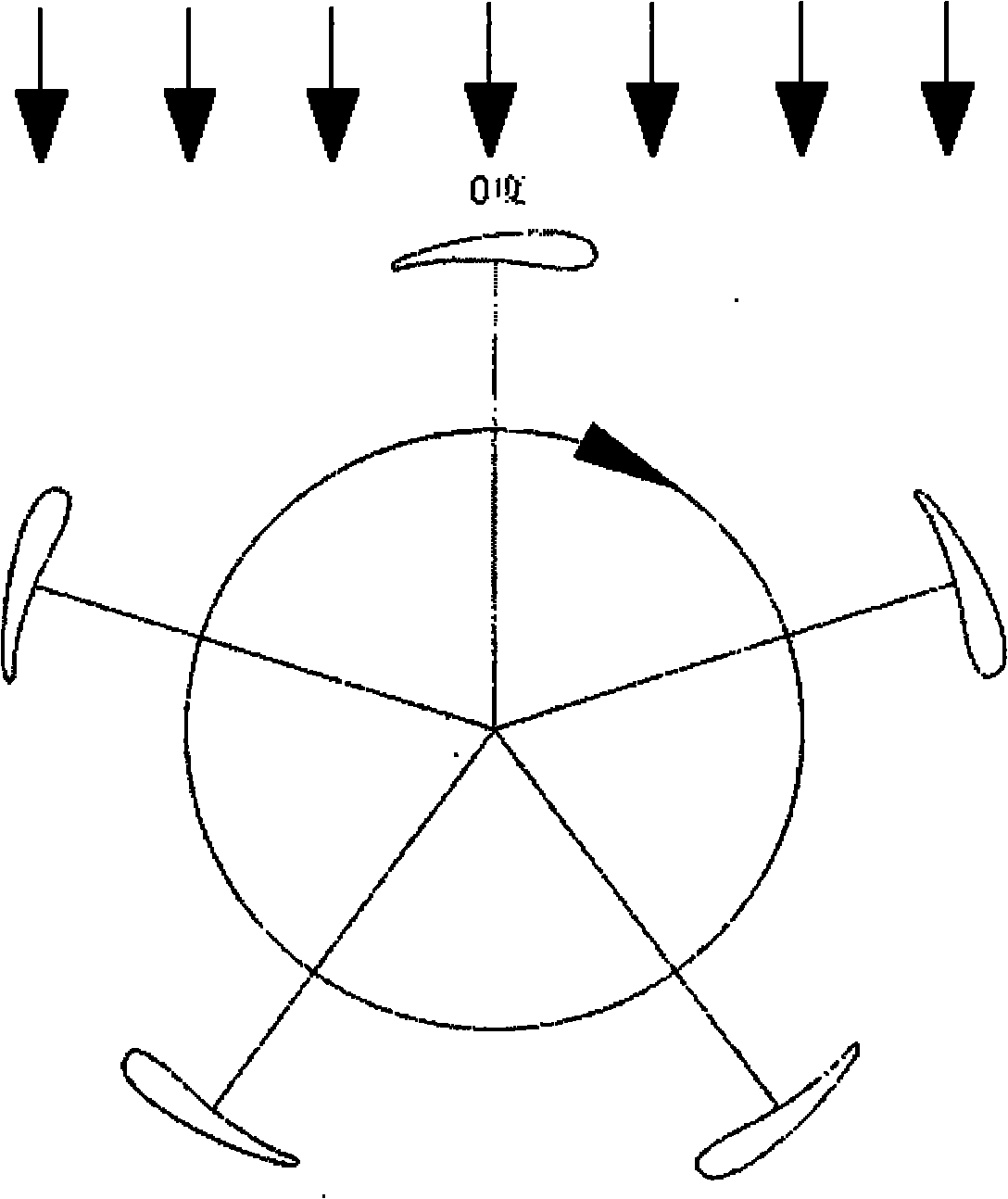

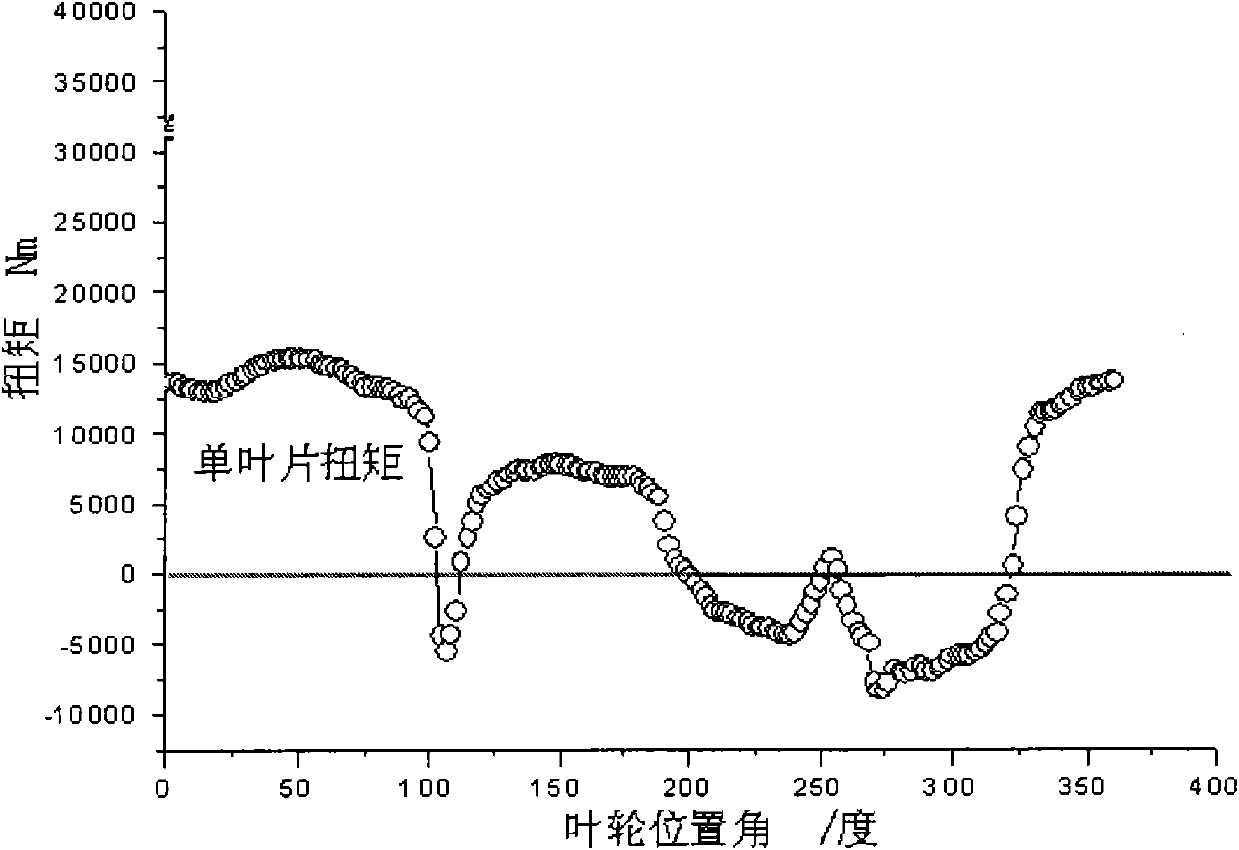

[0061] The high-efficiency and high-power vertical axis wind power generator provided by the present invention comprises a vertical blade wind wheel, which is rotatably fixed on a central tower column, and a plurality of blades are arranged on the wind wheel, and the wind wheel and the tower A generator set is arranged between the columns, the stator part of the generator set is arranged around the tower column, the rotor part is arranged on the outer periphery of the stator part, and is fixedly connected with the hub of the wind wheel;

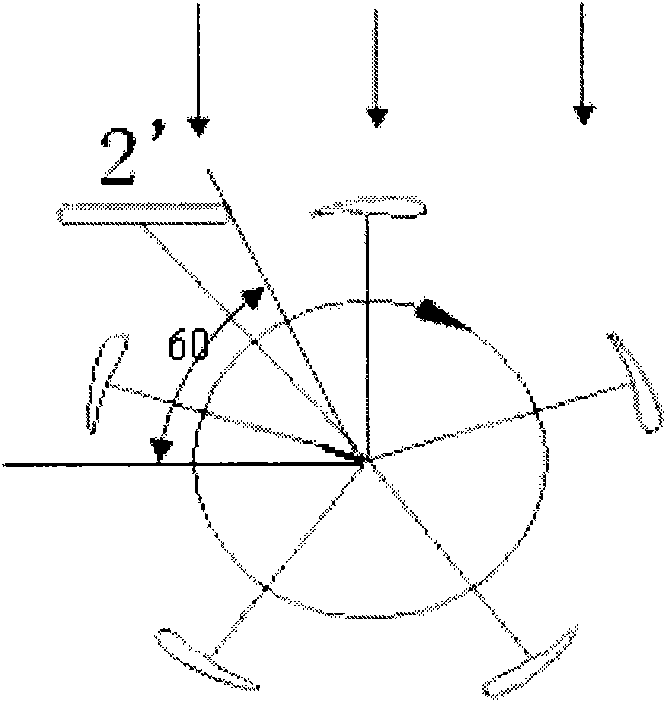

[0062] It also includes an energy booster wing, which is a windshield object, which is arranged on a support in a manner that does not block the rotation of the blades, and is located in front of the windward side of the wind wheel. The windshield surface corresponds to the blade on the windward side of the wind wheel that receives the incoming wind flow and is blocked from rotating, so that the side of the wind wheel that is blocked from rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com