Essential service water pump for nuclear power station

A nuclear power plant, an important technology, applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve the problems of low heat dissipation efficiency of bearings, failure to prevent liquid backflow, troublesome replacement and maintenance, etc., to achieve replacement Convenient and fast, avoiding the medium entering the ball bearing and increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a detailed description through specific examples and in conjunction with the accompanying drawings:

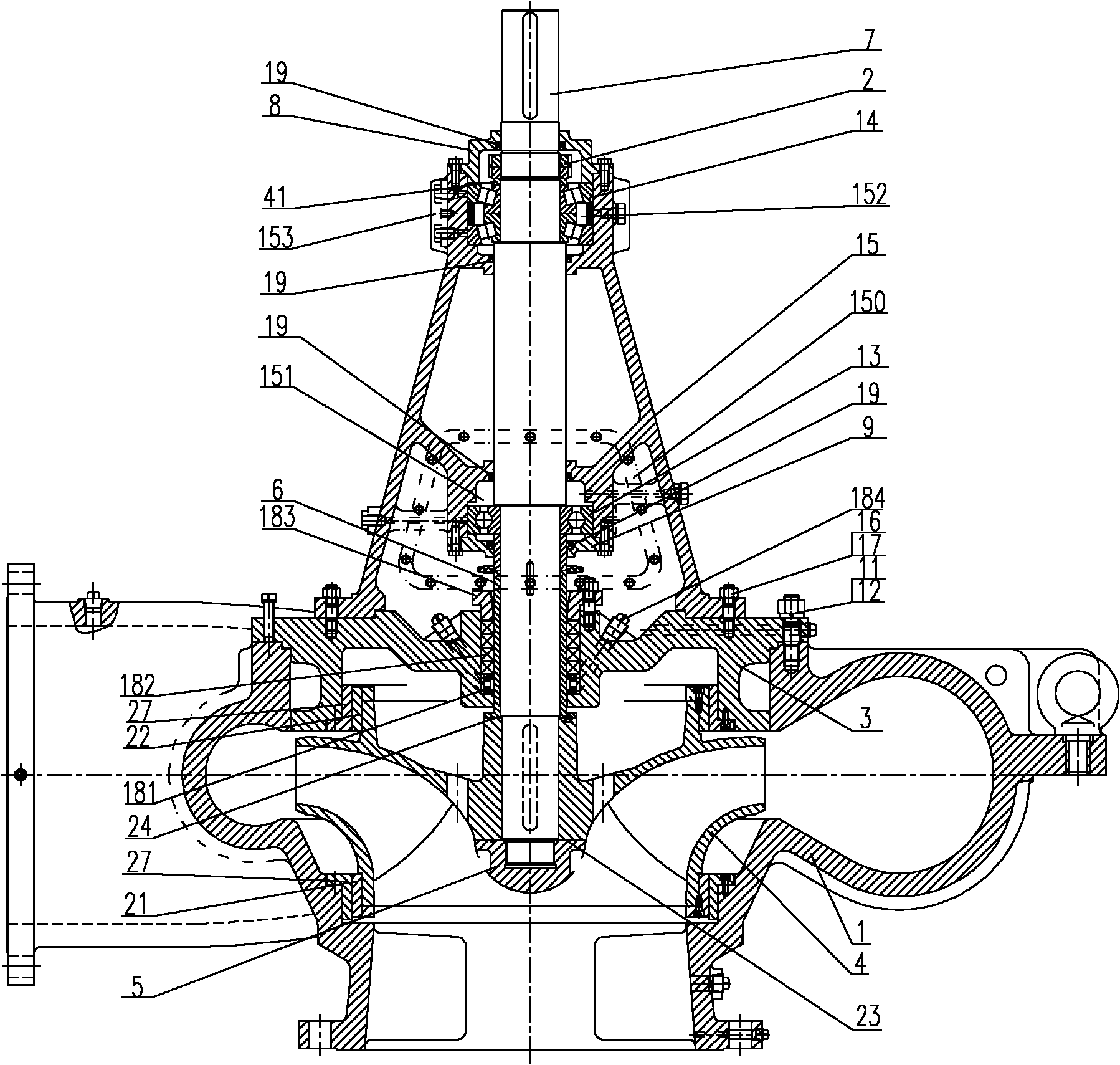

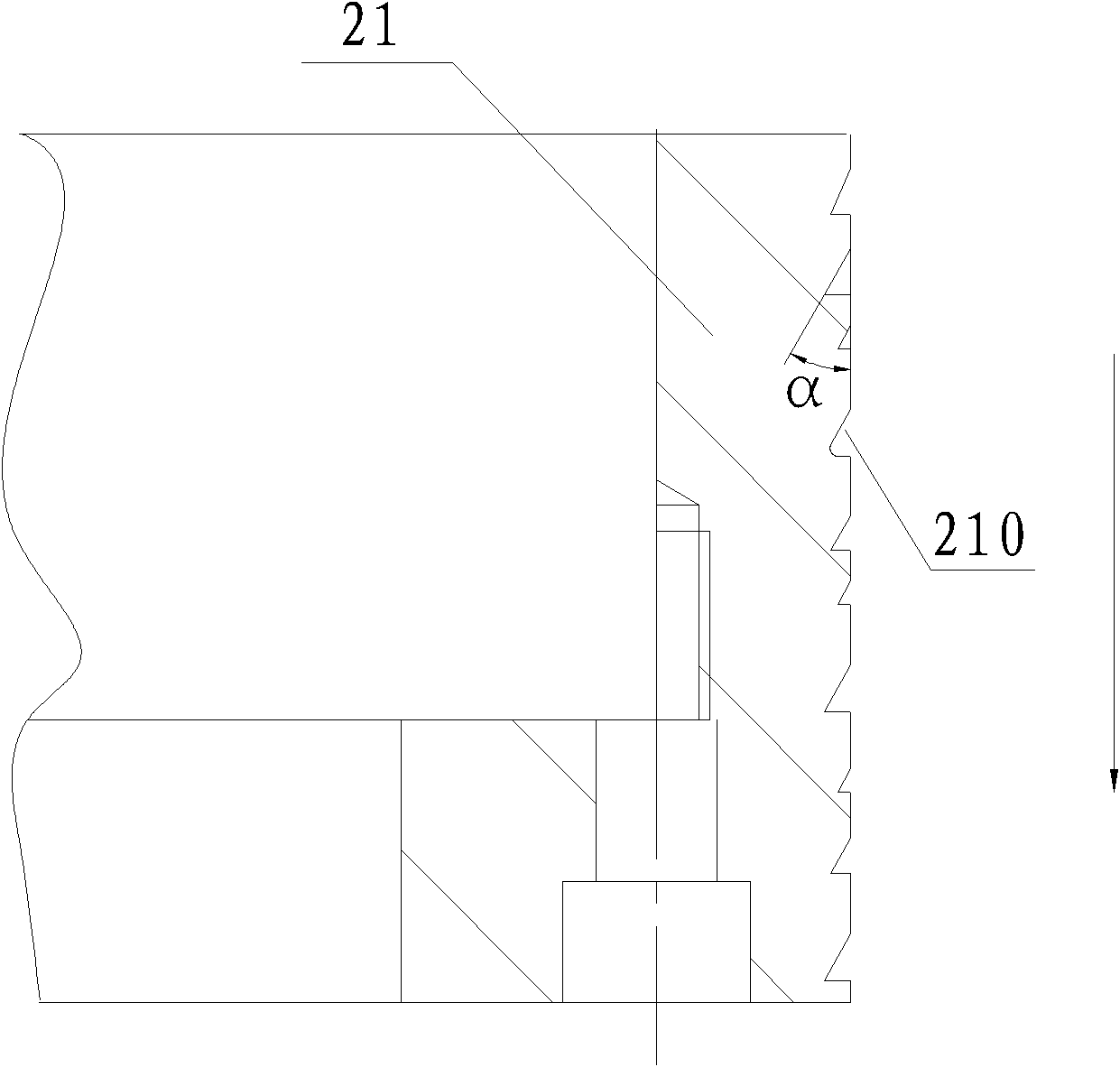

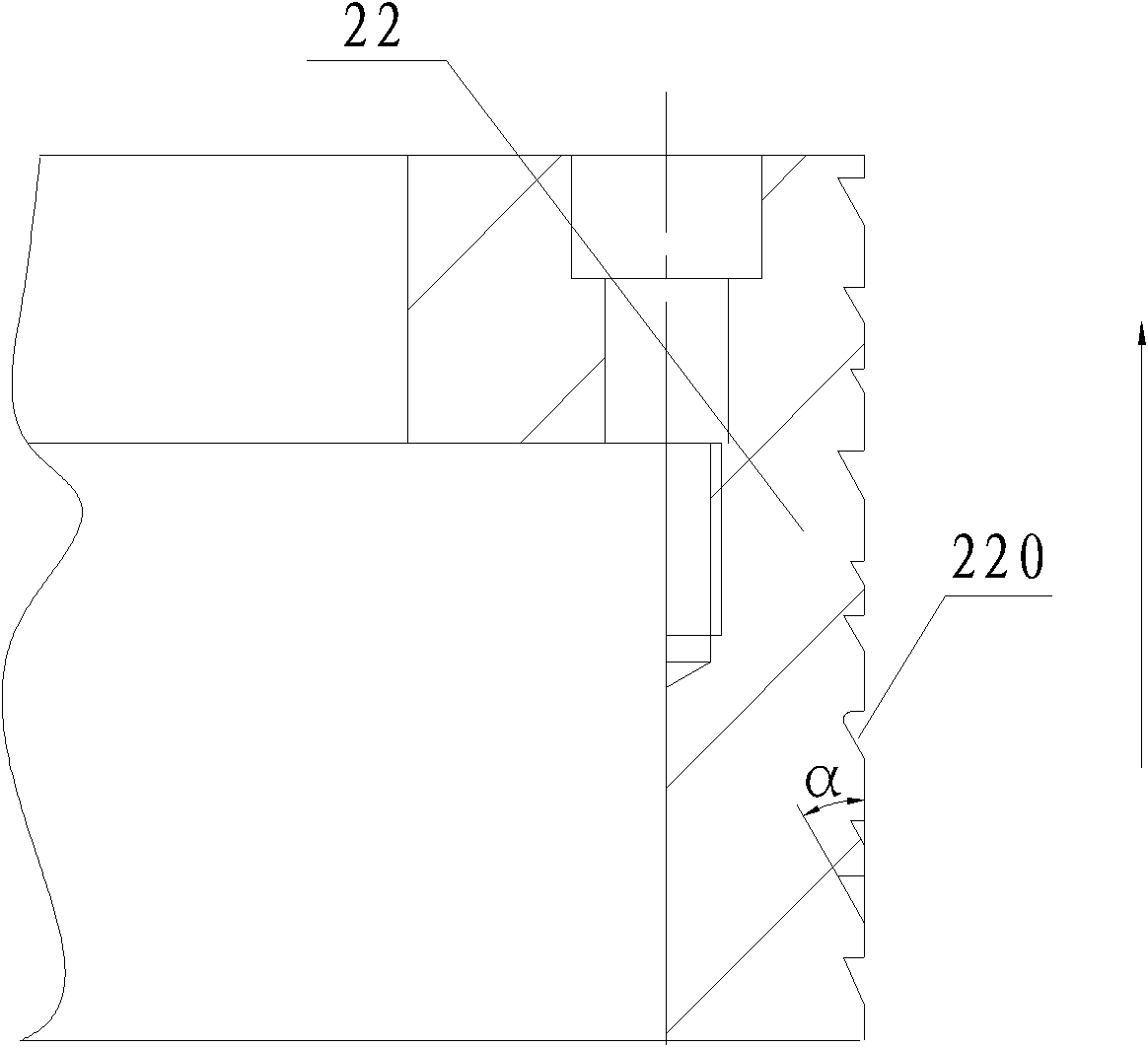

[0027] see figure 2 , an important service water pump of the present invention, comprising a stator assembly, a rotor assembly, a bearing assembly and a shaft seal assembly. The stator assembly includes a pump body 1, a pump cover 3 and front and rear sealing rings 21, 22; the rotor assembly includes a pump shaft 7, an impeller 4, an impeller nut 5 and a shaft sleeve 6; the bearing assembly includes a bearing body 15. Several bearings and upper and lower bearing glands 8 and 9; the shaft seal assembly includes pump body seal 18 and bearing oil seal. in:

[0028] The inner cavity of the pump body 1 has a volute structure;

[0029] A stuffing cavity 30 is provided on the upper end surface of the inner edge of the pump cover 3, and the outer edge of the pump cover 3 is mounted on the upper end surface of the pump body 1 and installed on the pump body 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com